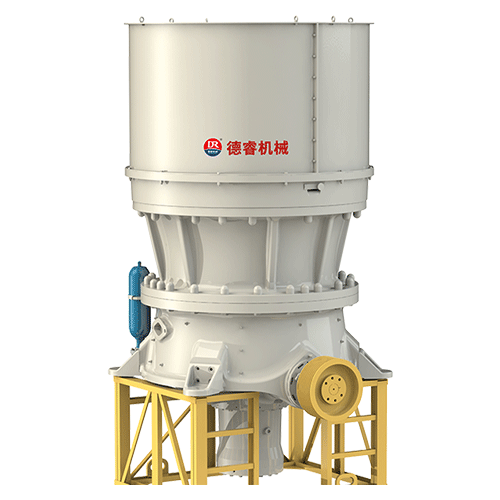

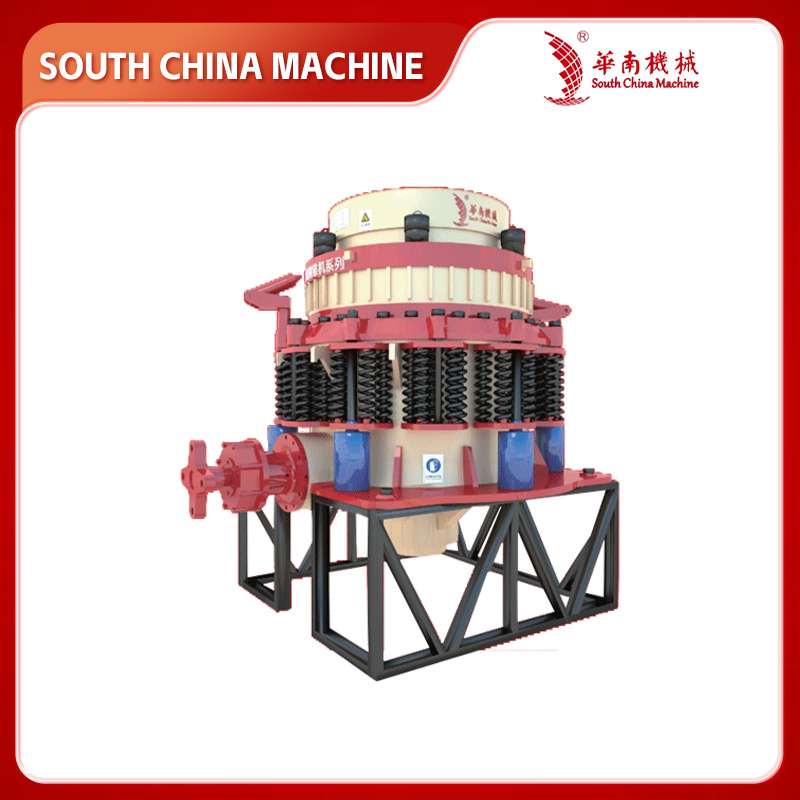

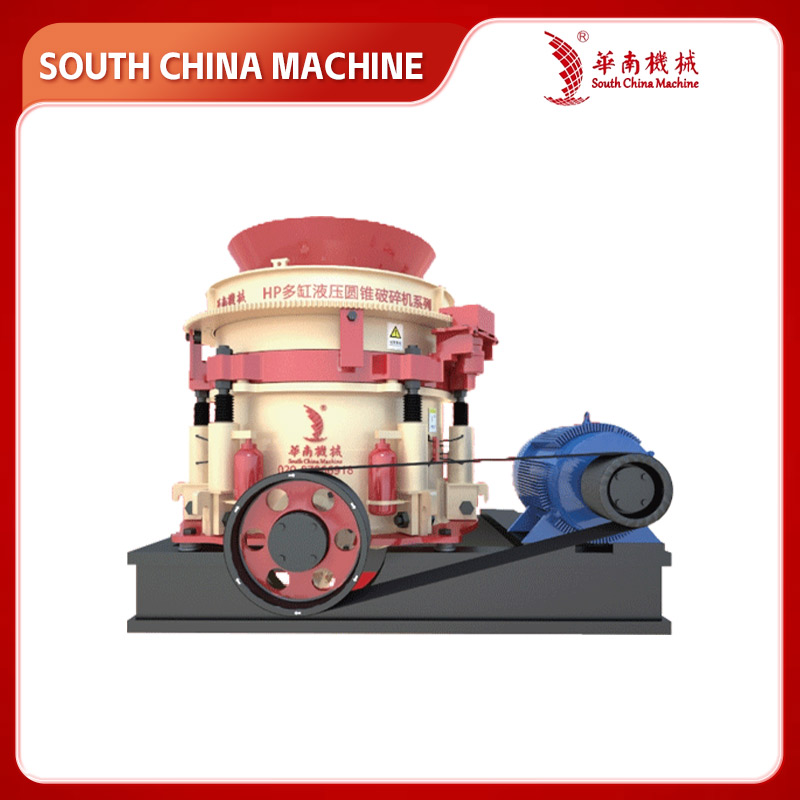

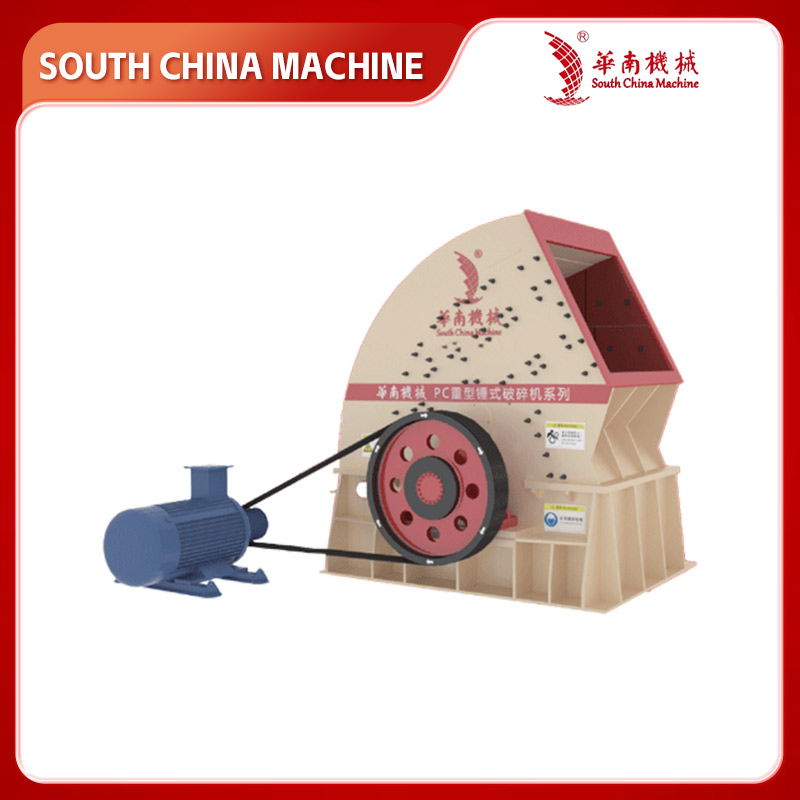

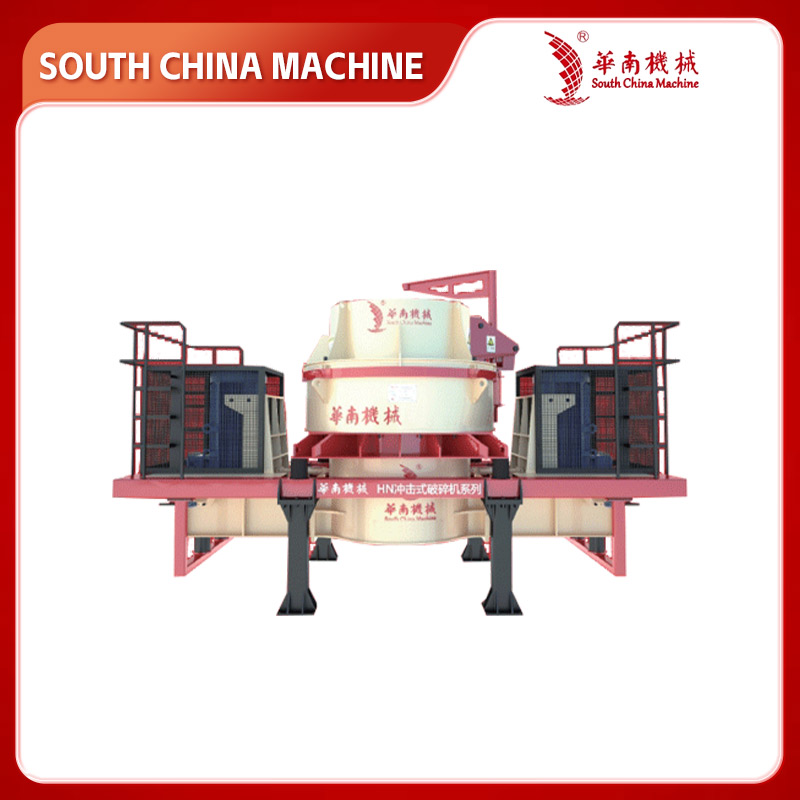

S/H SINGLE-CYLINDER HYDRAULIC CONE CRUSHER SERIES

S/H Series Single-Cylinder Hydraulic Cone Crusher is suitable for crushing raw materials in industries such as metallurgy, construction, road building, chemical engineering, and silicate production. It can efficiently process various ores and rocks of medium hardness and above, featuring large crushing ratio, high efficiency, low energy consumption, and uniform product size, making it ideal for intermediate and fine crushing of minerals and rocks.

PRODUCT FEATURES

1.Oil Lubrication System – Advanced and reliable, extending service life.

2.Simple Maintenance & Easy Operation – User-friendly design for convenient upkeep.

3.Advanced Hydraulic Technology – Provides overload protection and hydraulic discharge adjustment, simplifying the crusher structure and reducing weight.

4.Longer Crushing Chamber – Ensures high crushing ratio, efficiency, low power consumption, and uniform particle size, suitable for secondary & tertiary crushing.

5.Intelligent Control System – Supports automatic foreign object ejection, chamber clearing, and self-adjusting discharge setting.

TECHNICALSPECIFICATIONS

| A vaniety of crushing chamber types are avalable: :EEF=ultrafne, F=extra-fine, EFX=quasi-fne, F=fine, MF=medium fine, M=medium, MC=medium coarse, C=coarse, CX=quasi-coarse, EC= extra-thick | ||||||||||||

| Motor installation power (kw) |

Maximum feed size (mm) |

standard production capacity(t/h) under tight side discharge port CSS(mm) | ||||||||||

| 4 | 6 | 8 | 10 | 13 | 16 | 19 | 22 | |||||

| H crusher | H90 | 90 | EC | 135 | 46 | 50~85 | 54~92 | 58~99 | 62~105 | |||

| C | 90 | 43~53 | 46~89 | 50~96 | 54~103 | 57~110 | ||||||

| M | 65 | 36~44 | 38~74 | 41~80 | 45~76 | 48~59 | ||||||

| MF | 50 | 36 | 38~67 | 40~71 | 44~68 | 47~53 | ||||||

| F | 38 | 27~34 | 29~50 | 31~54 | 32~57 | 35~48 | 38 | |||||

| EF | 29 | 30~40(80% fineness less than 4.5~5.5mm) | ||||||||||

| H160 | 160 | EC | 185 | 69~108 | 75~150 | 80~161 | 86~171 | |||||

| C | 145 | 66~131 | 71~142 | 76~152 | 81~162 | |||||||

| MC | 115 | 57 | 62~140 | 67~151 | 72~162 | 77~173 | ||||||

| M | 90 | 64~84 | 69~131 | 75~142 | 80~152 | 86~162 | ||||||

| MF | 75 | 61 | 65~106 | 70~115 | 76~124 | 81~126 | 87~114 | |||||

| F | 50 | 48~78 | 51~83 | 54~88 | 59~96 | 63~103 | 68~105 | 72~95 | ||||

| EF | 35 | 70~90(80% fineness less than 5-5.6mm) | ||||||||||

| H250 | 250 | EC | 215 | 114~200 | 122~276 | 131~294 | ||||||

| C | 175 | 101 | 109~218 | 117~292 | 125~312 | |||||||

| MC | 140 | 97~122 | 105~262 | 113~282 | 120~301 | |||||||

| M | 110 | 117~187 | 126~278 | 136~298 | 145~318 | |||||||

| MF | 85 | 114 | 124~227 | 134~245 | 144-263 | 153~281 | ||||||

| F | 70 | 90~135 | 96~176 | 104~191 | 112~206 | 120~221 | 129~236 | |||||

| EF | 38 | 100-125(80% fineness less than 5~7.5mm) | ||||||||||

| H315 | 315 | EC | 275 | 177 | 190~338 | 203~436 | ||||||

| CX | 245 | 74~194 | 187-374 | 200~488 | ||||||||

| C | 215 | 171~190 | 184~367 | 196~480 | ||||||||

| MC | 175 | 162~253 | 1/4~426 | 186~455 | ||||||||

| M | 135 | 197~295 | 211~440 | 226~470 | ||||||||

| MF | 115 | 192 | 207~369 | 222~396 | 237~423 | |||||||

| F | 85 | 195~304 | 210~328 | 225~352 | 241~376 | |||||||

| EF | 65 | 211~293 | 227~316 | 244~298 | 261~290 | |||||||

| H500 | 500 | EC | 300 | 448~588 | ||||||||

| C | 240 | 406 | 433~636 | |||||||||

| MC | 195 | 380~440 | 406~723 | |||||||||

| M | 155 | 400~563 | 428~786 | |||||||||

| MF | 100 | 379~424 | 407~716 | 434~765 | ||||||||

| F | 90 | 357~395 | 385~656 | 414~704 | 442~752 | |||||||

| EF | 80 | 280~405 | 304~517 | 328~558 | 352~598 | 376~639 | ||||||

| CH880 | 600 | EC | 370 | |||||||||

| C | 330 | |||||||||||

| MC | 260 | 541 | ||||||||||

| M | 195 | 552~613 | ||||||||||

| MF | 130 | 514 | 549~933 | |||||||||

| F | 120 | 531 | 570~832 | 609~888 | ||||||||

| EFX | 100 | 401~502 | 433~631 | 465~678 | 496~724 | |||||||

| EF | 85 | 364~420 | 395~532 | 426~574 | 458~616 | 489~658 | ||||||

| EEF | 75 | 309~356 | 328~441 | 356~479 | 384~517 | 412~554 | 440~592 | |||||

| There are standard crushing chamber types to choose from: MC=medium coarse, C=coarse, EC= extra-thick Standard production capacity (t/h) under tight side discharge port CSS(mm) | ||||||||||||

| S crusher | Motor installation power (kw) |

Maximum feed size (mm) |

19 | 22 | 25 | 29 | 32 | 35 | 38 | 41 | ||

| S90 | 90 | EC | 240 | 85 | 92~115 | 101~158 | 107~168 | 114~143 | 121 | |||

| C | 200 | 70 | 76~95 | 82~128 | 90~112 | 96 | ||||||

| S160 | 160 | EC | 360 | 126 | 138~173 | 147~230 | 156~293 | 165~310 | 174~327 | |||

| C | 300 | 108 | 116~145 | 127~199 | 135~254 | 144~270 | 152~285 | 161~301 | ||||

| MC | 235 | 91 | 98~123 | 106~166 | 116~218 | 124~232 | 131~246 | 139~261 | 147-275 | |||

| S250 | 250 | EC | 450 | 267 | 282~353 | 298~446 | ||||||

| C | 400 | 225 | 239~299 | 254~381 | 269~484 | 284~511 | ||||||

| MC | 300 | 195 | 214~67 | 228~342 | 242~435 | 256~461 | 270~486 | |||||

| S315 | 315 | EC | 560 | 349 | ||||||||

| C | 500 | 318 | 336~420 | |||||||||

| A vaniety of crushing chamber types are avalable: :EEF=ultrafne, F=extra-fine, EFX=quasi-fne, F=fine, MF=medium fine, M=medium, MC=medium coarse, C=coarse, CX=quasi-coarse, EC= extra-thick | ||||||||||||

| H crusher | Motor installation power (kw) |

Maximum feed size (mm) |

standard production capacity(t/h) under tight side discharge port CSS(mm) | |||||||||

| 25 | 32 | 38 | 44 | 51 | 57 | 64 | 70 | |||||

| H90 | 90 | EC | 135 | 66~112 | 76~128 | |||||||

| C | 90 | 61~118 | 70 | |||||||||

| M | 65 | |||||||||||

| MF | 50 | |||||||||||

| F | 38 | |||||||||||

| EF | 29 | 30~40(80% fineness less than 4.5~5.5mm) | ||||||||||

| H160 | 160 | EC | 185 | 91~182 | 104~208 | 115~208 | ||||||

| C | 145 | 86~173 | 98~197 | 109~150 | ||||||||

| MC | 115 | 82~184 | 93~145 | |||||||||

| M | 90 | 91~154 | 104 | |||||||||

| MF | 75 | 92 | ||||||||||

| F | 50 | 77 | ||||||||||

| EF | 35 | 70-90(80% fineness less than 5-5.6mm) | ||||||||||

| H250 | 250 | EC | 215 | 139~313 | 159~357 | 175~395 | 192~384 | |||||

| C | 175 | 133~332 | 151~378 | 167~335 | 183~229 | |||||||

| MC | 140 | 128~320 | 146~328 | 161~242 | ||||||||

| M | 110 | 154~339 | 176~281 | 194 | ||||||||

| MF | 85 | 163~299 | 186~248 | |||||||||

| F | 70 | 137~251 | 156~208 | |||||||||

| EF | 38 | 100~125(80% fineness less than 6~7.5mm) | ||||||||||

| H315 | 315 | EC | 275 | 216~464 | 246~547 | 272~605 | 298~662 | 382~511 | ||||

| CX | 245 | 212~519 | 242-592 | 268~654 | 293~521 | 323~359 | ||||||

| C | 215 | 209~510 | 238~582 | 263~643 | 288~512 | 317~353 | ||||||

| MC | 175 | 198~484 | 226~552 | 249~499 | 732~364 | |||||||

| M | 135 | 240~500 | 274~502 | 302~403 | ||||||||

| MF | 115 | 252~450 | 287~451 | 318~363 | ||||||||

| F | 85 | 256~400 | 292~401 | 323 | ||||||||

| EF | 65 | |||||||||||

| H500 | 500 | EC | 300 | 477~849 | 544~968 | 601~1070 | 658~1172 | 725~1291 | 782~1393 | 849~1512 | 906~1331 | |

| C | 240 | 461~893 | 525~1018 | 581~1125 | 636~1232 | 700~1357 | 756~1464 | 820~1461 | 876~1286 | |||

| MC | 195 | 432~837 | 492~954 | 544~1055 | 596~1155 | 657~1272 | 708~1373 | 769~1370 | 821~1206 | |||

| M | 155 | 455~836 | 519~953 | 573~1054 | 628~1154 | 692~1271 | 746~1372 | 310~1248 | 865~1098 | |||

| MF | 100 | 462~814 | 527~928 | 592~942 | 638~789 | 702 | ||||||

| F | 90 | 470~800 | 535~912 | 592~857 | 649~718 | |||||||

| EF | 80 | 400~680 | 455~775 | 503~728 | 551~669 | |||||||

| H880 | 600 | EC | 370 | 480~640 | 547~1277 | 605~1411 | 662~1546 | 730~1702 | 787~1837 | 854~1994 | 912-2128 | |

| C | 330 | 540~772 | 616~1232 | 681~1362 | 746~1492 | 821~1643 | 886~1773 | 962~1924 | 1027~1613 | |||

| MC | 260 | 576~864 | 657~1231 | 726~1361 | 795~1490 | 876~1642 | 945~1771 | 1025~1538 | 1094~1231 | |||

| M | 195 | 587~1043 | 669~1189 | 739~1314 | 810~1440 | 892~1586 | 962~1604 | 1045~1393 | 1115 | |||

| MF | 130 | 584~993 | 666~1132 | 736~1251 | 806~1370 | 888~1420 | 958~1245 | |||||

| F | 120 | 648~945 | 739~985 | 816~885 | ||||||||

| EFX | 100 | 528~770 | 602~803 | 665~721 | ||||||||

| EF | 85 | 520~700 | 593~798 | 655~882 | 718~883 | 790 | ||||||

| EEF | 75 | 468~630 | 543~575 | |||||||||

| There are standard crushing chamber types to choose from: MC=medium coarse, C=coarse, EC= extra-thick Standard production capacity (t/h) under tight side discharge port CSS(mm) | |||||||||||||

| S crusher | Motor installation power (kw) |

Maximum feed size (mm) |

44 | 48 | 51 | 54 | 60 | 64 | 70×1.6 | 76 | 83 | ||

| S90 | 90 | EC | 240 | ||||||||||

| C | 200 | ||||||||||||

| S160 | 160 | EC | 360 | 183~344 | 196~306 | 205~256 | 214 | ||||||

| C | 300 | 169~264 | 108 | ||||||||||

| MC | 235 | 154~241 | 165 | ||||||||||

| S250 | 250 | EC | 450 | 313~563 | 334~601 | 349~524 | 365~456 | ||||||

| C | 400 | 298~448 | 318~398 | 338 | |||||||||

| MC | 300 | 284~426 | 303~378 | 317 | |||||||||

| S315 | 315 | EC | 560 | 368~460 | 392~588 | 410~718 | 428~856 | 465~929 | 89~987 | 525~1050 | 562~983 | 604 | |

| C | 500 | 353~618 | 376~753 | 394~788 | 411~823 | 446~892 | 469~822 | 504~631 | |||||

单缸液压圆锥破碎机2.png)