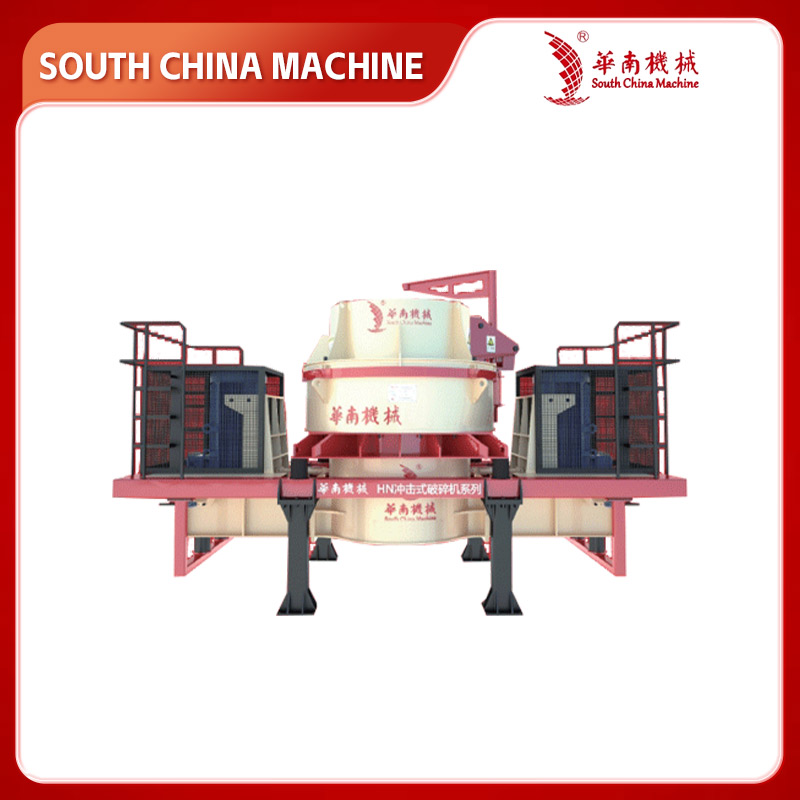

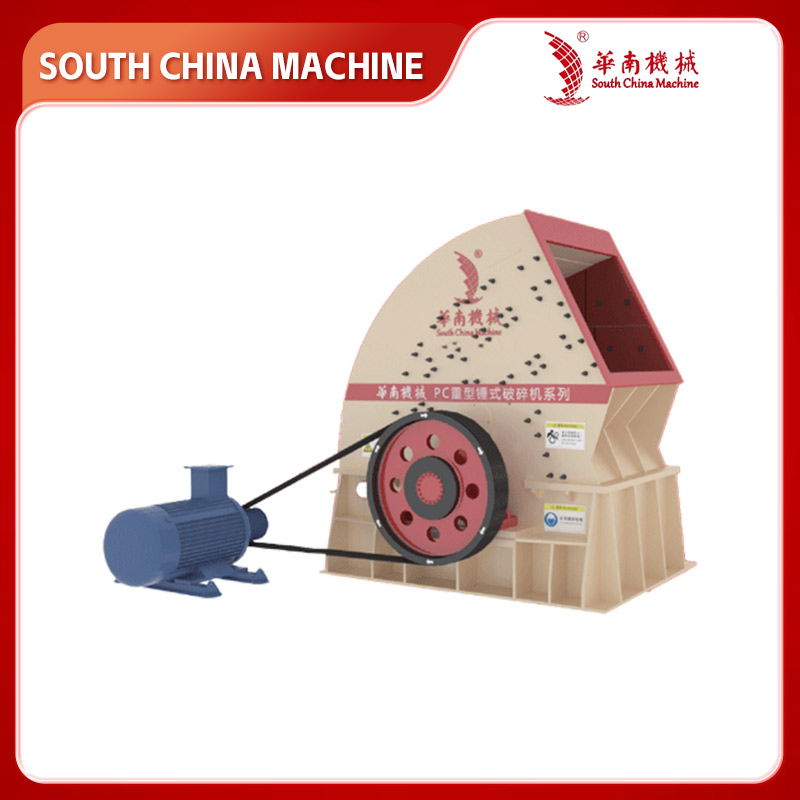

HN IMPACT CRUSHER SERIES

HN Impact Crusher is a high-energy, low-consumption equipment developed by our company with international advanced standards. It incorporates cutting-edge technology from similar products of American Barmac Company, building upon our extensive experience in designing and manufacturing mining machinery. Its performance plays an irreplaceable role among various fine crushing equipment for ores. The vertical shaft impact crusher has a long history of design and production in China, featuring high reliability, easy operation, installation, and maintenance. It supports multiple crushing modes (rock-on-rock and rock-on-iron) to meet different user requirements for crushing. Various components are available, with key parts sourced from internationally renowned brands. It offers a wide range of material suitability and is characterized by energy efficiency, environmental friendliness, and the need for no additional accessories. It is widely used in high-quality artificial sand production and aggregate shaping, as well as fine and ultra-fine crushing in industries such as cement pre-grinding and refractory materials, processing materials like granite, basalt, limestone, quartzite, gneiss, cement clinker, concrete aggregates, ceramic raw materials, iron ore, gold ore, copper ore, corundum, bauxite, and silica.

PRODUCT FEATURES

1.Raw materials fall into the feed hopper and enter the rotor through the central inlet. The high-speed rotor accelerates the materials and ejects them at 60–75 m/s. The materials are crushed upon impact with the crushing cavity lining, and the final product is discharged through the outlet.

2.Materials drop into the feed hopper, where they are split into two streams by a specially designed plate. One stream enters the rotor through the center of the plate, while the other stream falls along the outer edge of the plate. This ensures continuous and repeated crushing of the materials.

3.Fully hydraulic system: Includes hydraulic opening for maintenance cover, two-side motor adjustment, and hydraulic jacking for the crushing chamber.

TECHNICAL SPECIFICATIONS

| Model | Maximum feed size(mm) | Linear Velocity (m/s) |

Capacity(t/h) |

Motor power(kw) |

Overall dimensions(mm) |

| HN6000 | 40 | 60-89 | 53-240 | 160 | 3600×1970×3290 |

| HN7000 | 40 | 60-89 | 80-430 | 250 | 3910×2180×3810 |

| HN7500 | 40 | 60-89 | 100-450 | 132×2 | 5000×2180×3810 |

| HN8000 | 40 | 60-89 | 188-520 | 160×2 | 5200×2540×3910 |

| HN8500 | 40 | 60-89 | 230-550 | 200×2 | 5200×2540×3910 |

| HN9000 | 50 | 60-89 | 275-600 | 250×2 | 5810×2540×3910 |

| HN9500 | 50 | 60-89 | 290-650 | 280×2 | 5810×2540×3910 |

| HN10000 | 50 | 60-89 | 320-720 | 315×2 | 5810×2540×3910 |

APPLICATION CASES

8HL.png)