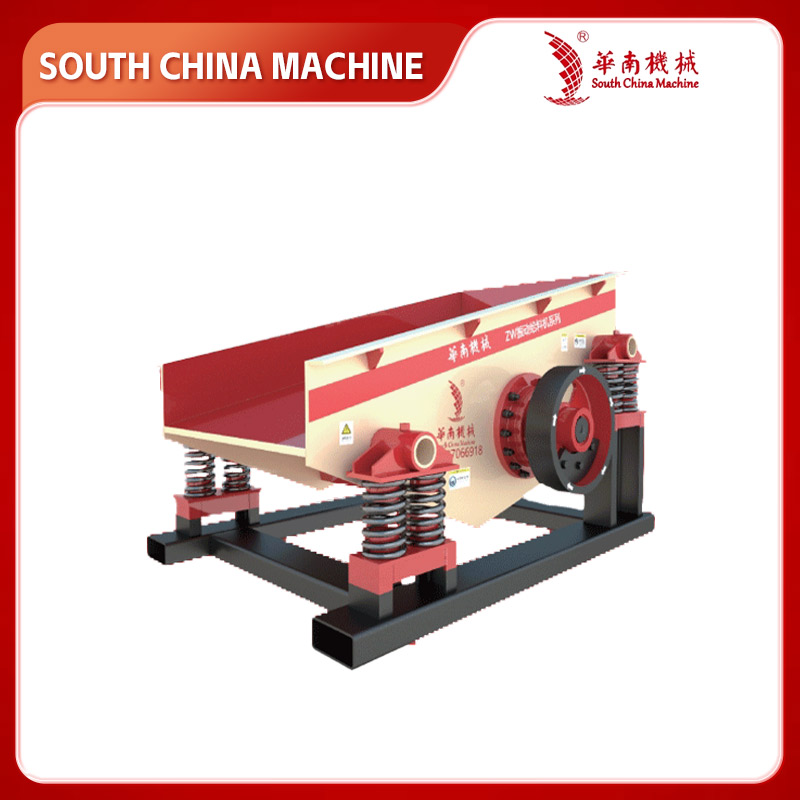

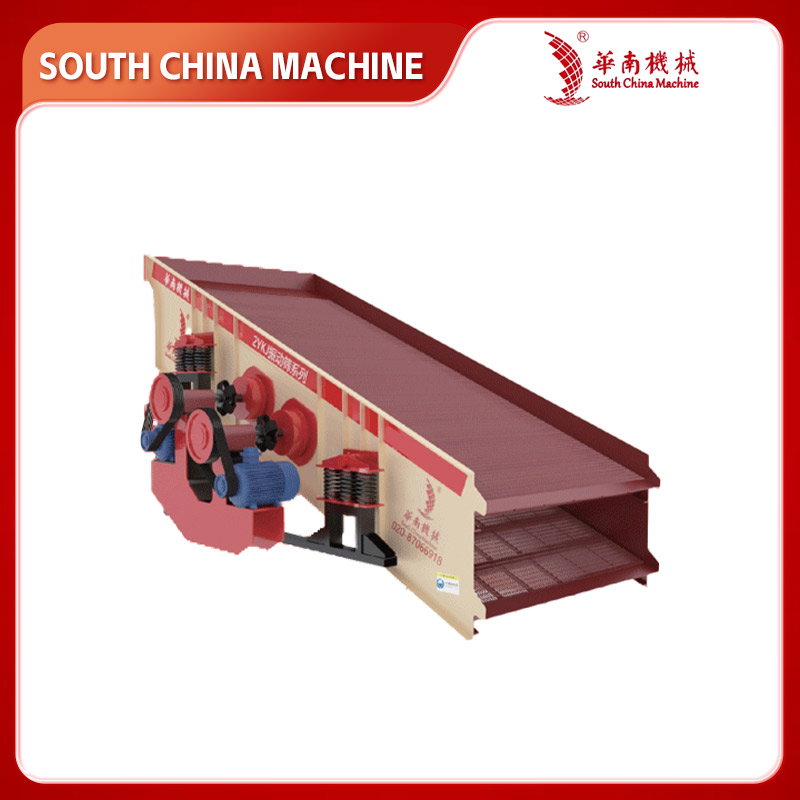

HED SUPER DEHYDRATING SIEVE SERIES

Through the reverse motion of dual motors, vibrational force is transmitted, which alters the water tension within the sand and slurry mixture. The slurry water passes through the screen mesh to become the underflow, while fine materials are retained by the screen mesh to form a filter layer. This filter layer, influenced by the vibrational force, moves linearly forward and is discharged from each layer's outlet. The equipment is primarily used for wet and dry classification, dehydration, and desliming of fine particulate materials during sand production and washing in various mining operations. Featuring high vibration frequency, high vibration force, and utilizing eccentric blocks and eccentric shafts as the vibrational force source, the screening machine boasts a simple structure, facilitating quick and easy maintenance. Compared to similar products of the same size, it offers higher production capacity and superior output quality.

PRODUCT FEATURES

1.It features a compact structure with high rigidity and strength throughout the entire machine.

2.With a relatively small volume, it boasts high processing capacity per unit area, facilitating systematic process layout.

3.It consumes relatively little energy while offering a high dehydration rate. Installation and debugging are convenient, operation is reliable, and maintenance is easy.

4.The screen mesh structure and types are modularized, facilitating easy replacement.

5.Compared to other similar products of the same size, it offers greater production capacity.

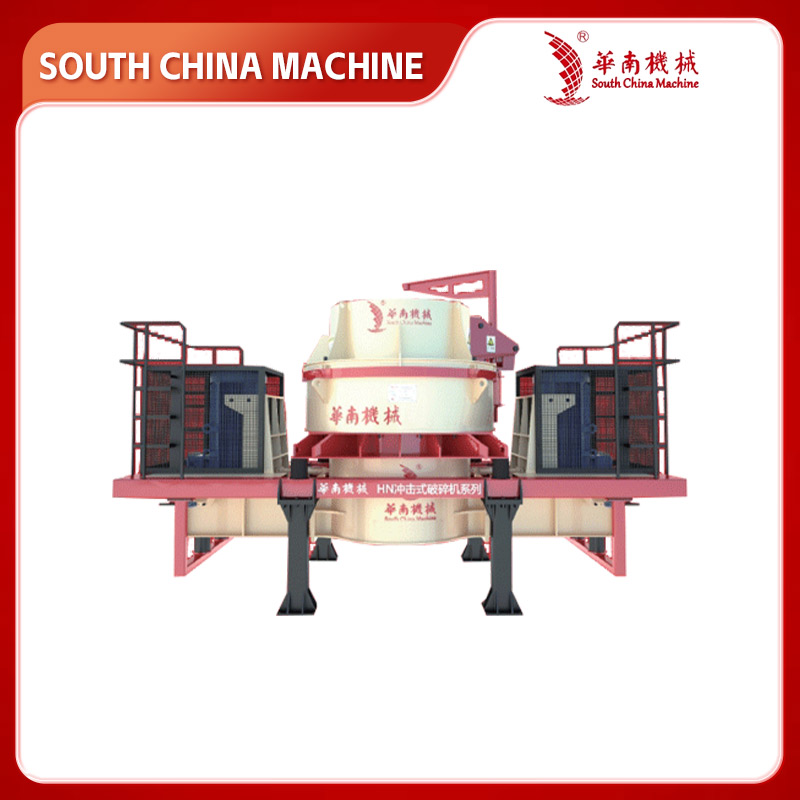

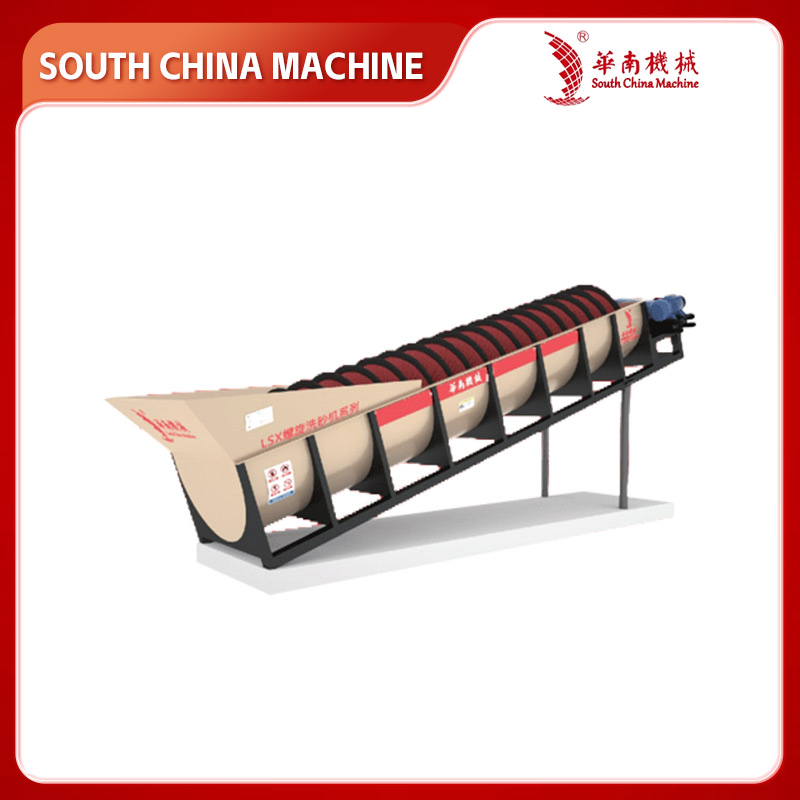

6.The sand washing and recovery integrated machine is a screening and fine sand recovery equipment developed specifically for dewatering, desliming, and de-medium of slurry materials.

7.The cylindrical vibrator is directly installed on the screen box, eliminating the need for bulky I-beam cross members. This results in a lower overall height of the screen box, a lowered center of gravity, reduced weight, and increased stability during operation of the seated screening machine.

8.The vibrational force is equivalent to a uniformly distributed load along the entire width of the screen, making it easier to ensure installation accuracy. The error has a minimal impact on the amplitude at various points on the screen box.

TECHNICAL SPECIFICATIONS

| Model | Shape dimennsion (mm) |

Capacity (t/h) |

Motor power (kw) |

Amplitude (mm) |

Rotational speed (r/min) |

Sieve structure |

| 2450 Single Layer | 5300*1630*3100 | 150-250 | 18.5*2 | 8-14 | 960 | woven, slotted, stamped, rubber, and polyurethane screen meshes |

| 2460 Single Layer | 6300*1830*3100 | 180-300 | 18.5*2 | 8-14 | 960 | |

| 2760 Single Layer | 6300*1830*3400 | 200-350 | 22*2 | 8-14 | 960 | |

| 2760 Double Layer | 7300*2650*3400 | 200-350 | 22*2 | 8-14 | 960 | |

| 3060 Single Layer | 6300*1930*3700 | 250-400 | 22*2 | 8-14 | 960 | |

| 2760 Double Layer | 6900*2770*3700 | 250-400 | 30*2 | 8-14 | 960 | |

| 2760 Double Layer | 8200*2875*4400 | 350-600 | 37*2 | 8-14 | 960 |

APPLICATION CASES

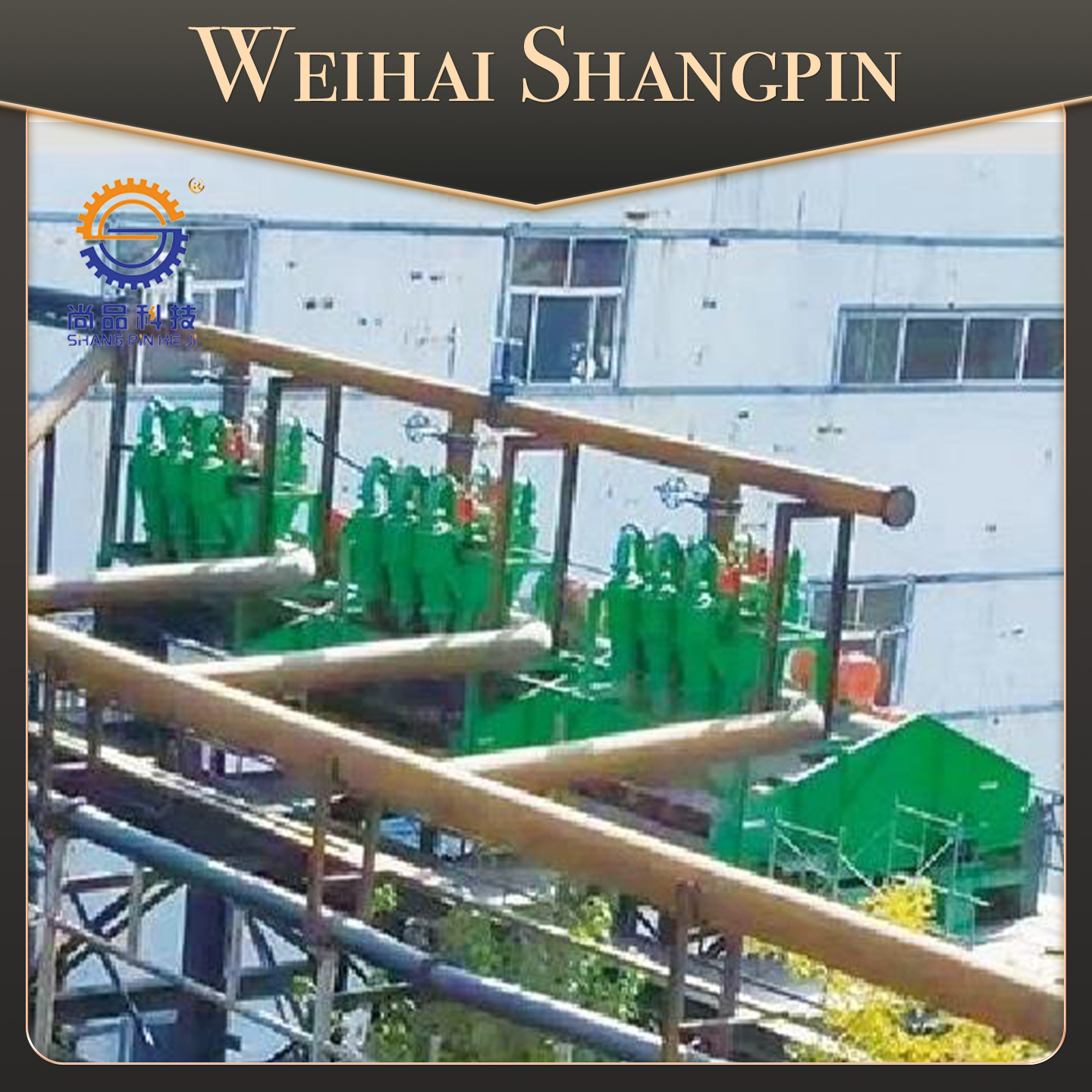

HS-T脱水筛.png)