<

>

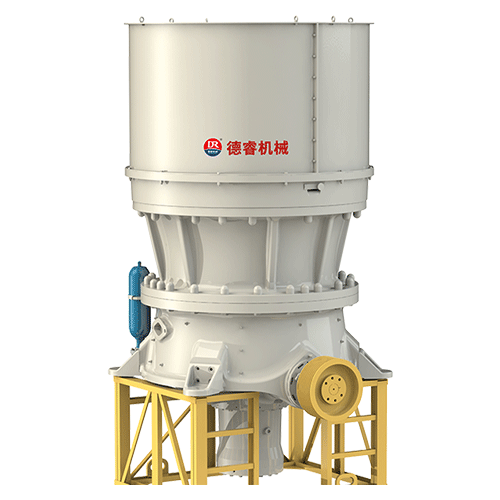

MG Series Single Cylinder Hydraulic Cone Crusher

Model:

MG550

Maximum Feed Size:

235mm

Throughput:

150-800t/h

Total Weight:

27.2t

COLLECT

Hansy Mining Co., Ltd.

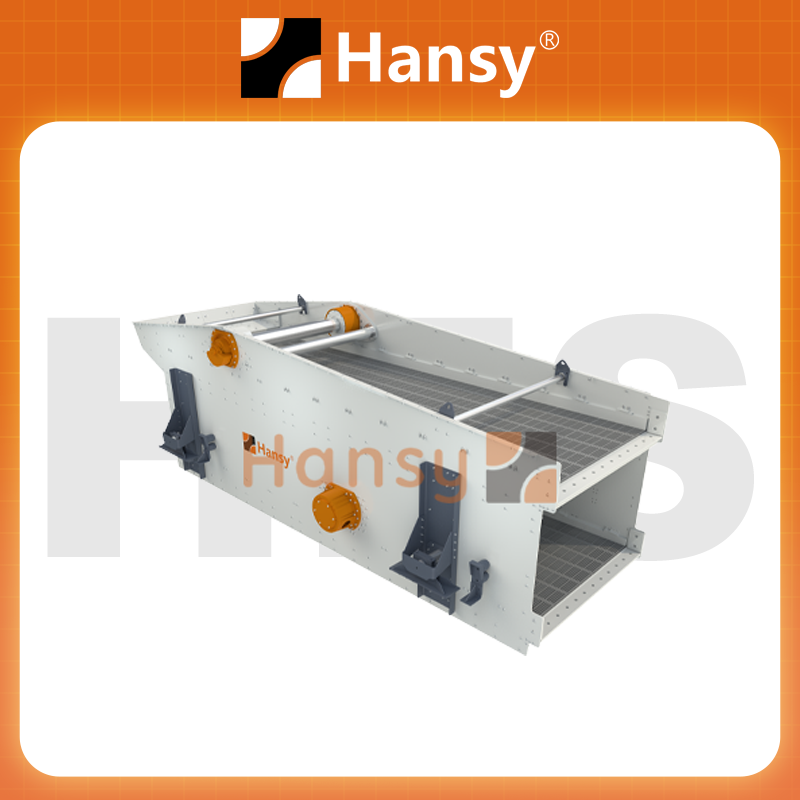

Main Products:Sand making machine, single bar hydraulic cone crusher, multi cylinder hydraulic cone crusher, jaw crusher, impact crusher, rotary crusher, vertical shaft impact crusher, banana screen, elliptical screen, horizontal screen, circular vibrating screen, vibrating feeder

Enter the store

︿

﹀

Details Parameters

Details Introduction

Designed according to heavy-duty working conditions, it can be applied to crushing operations in mines and stone industries of various scales. Among them, the suffix "s" series with larger grain size can be used as coarse and medium crushing,and no suffix"s" can be used as medium and fine crushing.This series of crushers has the advantages of low cost, simple operation and wide range of use.

TECHNICAL FEATURES

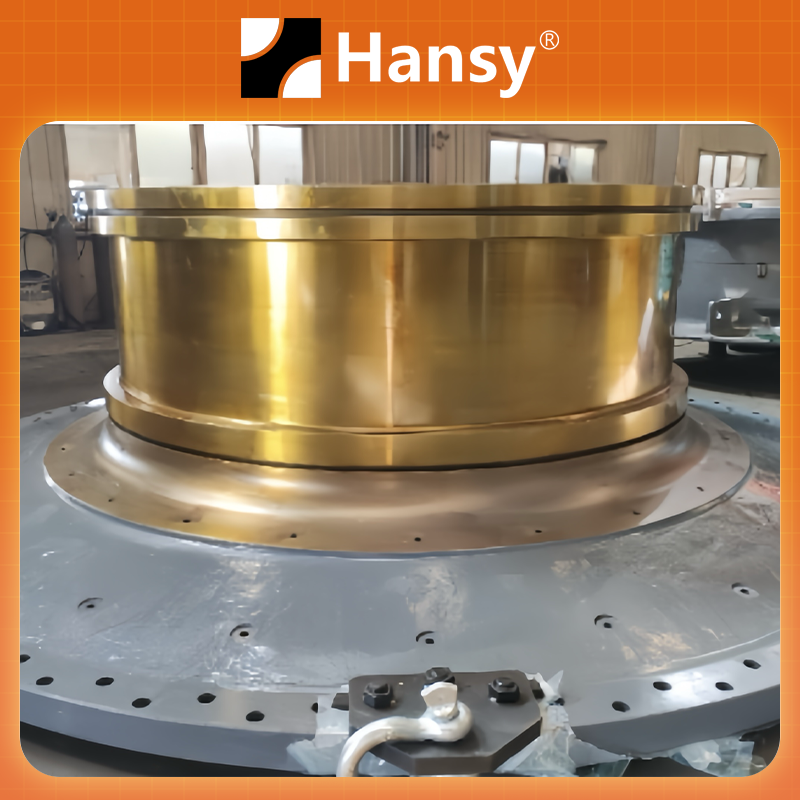

- The frame finite element analysis optimizes the structure and large diameter spindle design, greatly improving the reliability of the equipment.

- Cavity optimization design, large feeding port, large throughput and good particle shape.

- By changing the lining plate and setting a plurality of eccentricities, it can adapt to various ore characteristics and working conditions.

- The equipment is simple to operate, the lining plate installation does not need packing, all parts of the crusher can be lifted from the upper part, and the vulnerable parts can be easily replaced.

- Spiral bevel gears are used for large and small gears to achieve high energy efficiency and large torque transmission.

TECHNICAL PARAMETERS

| Model | Maximum Feed Size(mm) | Motor Power(kw) | Outlet(mm) | Processing Capacity(t/h) | Equipment Weight(t) |

| MG100S | 210 | 90 | 20-45 | 80-240 | 7.5 |

| MG200S | 290 | 160 | 25-50 | 110-430 | 11.2 |

| MG300S | 330 | 250 | 25-50 | 190-500 | 16.5 |

| MG500S | 440 | 355 | 45-80 | 300-950 | 33.5 |

| MG700S | 450 | 560 | 30-90 | 350-1800 | 63.5 |

| MG110 | 135 | 90 | 7-25 | 35-115 | 6.0 |

| MG220 | 205 | 220 | 8-35 | 70-310 | 10.5 |

| MG330 | 215 | 315 | 8-35 | 110-470 | 16.0 |

| MG550 | 235 | 400 | 10-45 | 150-800 | 27.2 |

Related product recommendations

More Products >

CHENGDU DAHONGLI MACHINERY CO., LTD.

Henan Liming Heavy Industry Technology Co., Ltd

Fujian Derui Industrial Technology Group Co., Ltd.

单缸液压圆锥破碎机2.png)

单缸液压圆锥破碎机.png)