Introduction to Features

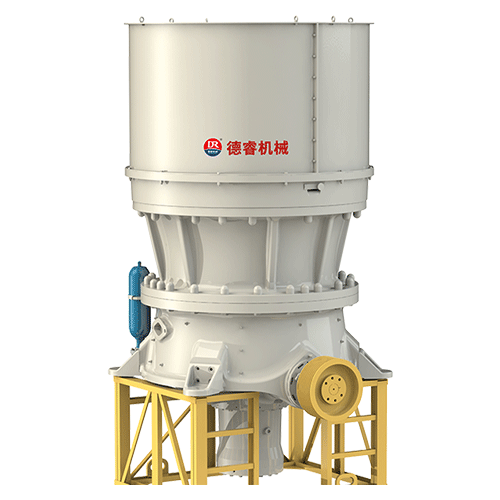

The RC series cone crusher is optimized and designed based on the absorption of advanced crushing technology from around the world, and is widely used in the second, third, or fourth stage crushing of mines. This series of machines has the following advantages:

1. The entire machine adopts CAD optimized design, with a large diameter high-strength spindle and a heavy-duty main frame to make the equipment more sturdy and durable;

2. The use of heavy-duty rolling bearings instead of traditional copper sleeves reduces the fit clearance and increases the spindle swing speed, resulting in larger production and better particle size;

3. Adopting a hydraulic control system, it facilitates the adjustment of the discharge port and provides more reliable overload protection;

4. The stroke can be changed according to the properties of the material. Adapt to different crushing needs;

5. Advanced automation control system improves product quality and maintains maximum crushing efficiency within a safe range;

6. Apply the principle of "laminated crushing" and optional speed, steep angle, and hyperbolic crushing chamber types to ensure perfect and consistent product particle shape;

7. Each model has multiple crushing chambers to choose from, which can better meet customer needs;

8. The upper frame is divided into two parts: the arm frame and the crushing wall bearing seat. If damaged, it can be separated up and down for easy maintenance and cost reduction;

9. Adopting spiral bevel gear transmission increases the bearing capacity and makes the operation more stable;

10. The whole machine has a simple structure and is easy to operate, greatly reducing maintenance time for workers and improving production efficiency.

Technical Parameter

|

Model |

Size of feeding port(mm) |

Discharge port size(mm) |

Power(kW) |

Weight(kg) |

|||||||||||||

|

Open circuit output(t/h) |

|

||||||||||||||||

|

10 |

12 |

14 |

16 |

18 |

20 |

22 |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

|

|||

|

RC43 |

90 |

110-165 |

115-170 |

120-180 |

125-190 |

130-195 |

135-205 |

140-210 |

170-220 |

|

|

|

|

|

|

200-250 |

24500 |

|

115 |

120-164 |

125-190 |

130-195 |

140-210 |

145-220 |

155-235 |

165-250 |

200-260 |

215-280 |

|

|

|

|

|

|||

|

150 |

|

135-206 |

145-220 |

155-235 |

165-250 |

175-260 |

185-275 |

220-285 |

240-310 |

260-340 |

|

|

|

|

|||

|

220 |

|

|

|

|

190-285 |

200-300 |

205-310 |

250-325 |

270-350 |

290-380 |

315-410 |

|

|

|

|||

|

250 |

|

|

|

|

|

215-325 |

230-345 |

280-365 |

300-390 |

325-425 |

350-455 |

380-495 |

|

|

|

||

|

RC50 |

110 |

215-325 |

225-340 |

235-355 |

250-375 |

265-395 |

275-415 |

290-435 |

350-455 |

|

|

|

|

|

|

250-315 |

30500 |

|

150 |

|

255-380 |

265-400 |

280-420 |

295-440 |

305-460 |

325-485 |

390-510 |

410-535 |

|

|

|

|

|

|||

|

220 |

|

|

|

320-480 |

330-495 |

340-510 |

350-525 |

415-540 |

435-565 |

455-590 |

|

|

|

|

|||

|

250 |

|

|

|

|

325-485 |

340-510 |

355-535 |

430-560 |

450-585 |

475-620 |

500-650 |

|

|

|

|||

|

340 |

|

|

|

|

|

335-500 |

350-525 |

425-555 |

460-600 |

495-645 |

535-695 |

580-755 |

625-815 |

|

|||

|

RC55 |

110 |

265-375 |

275-390 |

285-405 |

300-425 |

315-445 |

325-465 |

340-485 |

400-505 |

|

|

|

|

|

|

315-355 |

32500 |

|

150 |

|

315-445 |

330-465 |

345-485 |

360-505 |

370-525 |

390-550 |

455-575 |

475-600 |

|

|

|

|

|

|||

|

250 |

|

|

|

|

400-560 |

315-585 |

430-610 |

505-635 |

525-660 |

550-695 |

575-725 |

|

|

|

|||

|

340 |

|

|

|

|

|

420-580 |

435-610 |

510-640 |

545-685 |

580-730 |

620-780 |

665-850 |

710-900 |

|

|||

|

RC65 |

110 |

385-540 |

410-575 |

435-610 |

460-645 |

490-685 |

520-725 |

550-770 |

625-815 |

672-880 |

|

|

|

|

|

355-400 |

52000 |

|

150E |

|

495-740 |

505-760 |

520-780 |

535-805 |

555-830 |

575-860 |

680-885 |

715-930 |

750-975 |

|

|

|

|

|||

|

225 |

|

|

|

|

506-760 |

535-800 |

560-840 |

675-880 |

730-950 |

790-1030 |

850-1105 |

920-1195 |

|

|

|||

|

380 |

|

|

|

|

|

|

550-830 |

660-880 |

740-960 |

800-1000 |

900-1100 |

930-1200 |

1050-1350 |

1200-1400 |

|||

|

450 |

|

|

|

|

|

|

535-805 |

680-885 |

750-975 |

825-1075 |

905-1175 |

995-1295 |

1095-1425 |

1205-1565 |

|||

|

RC70 |

110 |

|

|

535-710 |

560-745 |

590-785 |

620-825 |

650-870 |

725-915 |

772-980 |

|

|

|

|

|

400-450 |

56000 |

|

150 |

|

|

655-910 |

670-930 |

685-955 |

705-980 |

725-1010 |

830-1030 |

865-1080 |

900-1125 |

|

|

|

|

|||

|

380 |

|

|

|

|

|

|

750-1030 |

860-1080 |

940-1160 |

1000-1200 |

1100-1300 |

1130-1400 |

250-1550 |

|

|||

|

450 |

|

|

|

|

|

|

|

880-1085 |

950-1175 |

1200-1275 |

1220-1375 |

1240-1495 |

1295-1625 |

1405-1700 |

|||

|

RC80 |

110 |

695-975 |

740-1035 |

785-1100 |

835-1170 |

885-1240 |

930-1305 |

990-1385 |

|

|

|

|

|

|

|

560-630 |

103000 |

|

150 |

795-1035 |

840-1095 |

890-1160 |

945-1233 |

1005-1305 |

1065-1385 |

1130-1470 |

1200-1560 |

|

|

|

|

|

|

|||

|

380 |

|

|

950-1230 |

1000-1295 |

1050-1360 |

1100-1425 |

1185-1540 |

1280-1660 |

1630-1790 |

1485-930 |

|

|

|

|

|||

|

550 |

|

|

|

|

|

|

|

1090-1420 |

1200-1565 |

1320-1720 |

1455-1895 |

1600-2085 |

1760-2295 |

1940-2525 |

|||

单缸液压圆锥破碎机2.png)