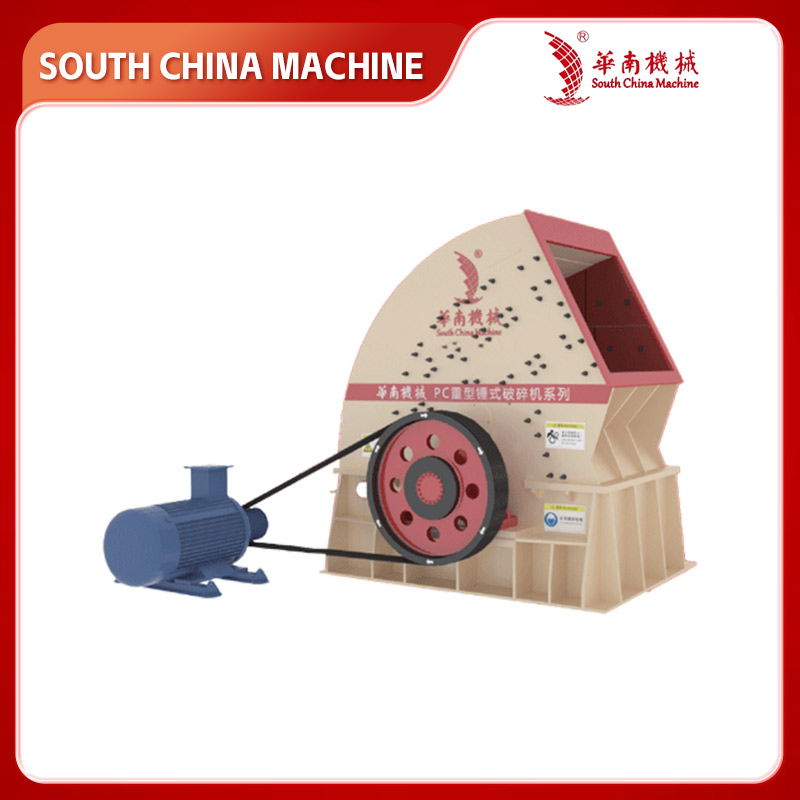

PCX HAMMER SAND MAKING MACHINE SERIES

PCX hammer sand making machine series is a highly efficient fine crushing equipment developed with advanced fine crushing technology. It is widely used for high-efficiency fine crushing and sand-making operations of medium-to-low hardness materials such as limestone, gypsum, cement clinker, dolomite, and iron ore. When used in the pre-grinding process before a ball mill, it can significantly improve productivity. With high sand-making efficiency, low energy consumption, and uniquely designed hammers that can be rotated to utilize all four sides, the hammers feature a long service life, high utilization rate, and superior performance.

PRODUCT FEATURES

1.The hammer crusher has a large feed size and small discharge size, transforming three-stage crushing into single-stage crushing, completely achieving low-cost operation where one crushing stage replaces two. Thus, it can reduce costs by 35%. It is an energy-efficient and low-investment equipment.

2.Also known as a giant rock crusher, the hammer crusher is optimized based on the mechanical principles of ordinary hammer crushers, impact crushers, vertical shaft hammer crushers, and other crushing machines that use hammers (or blow bars) to break rocks. After optimization, it represents the latest generation of crushing equipment. By changing the method of controlling discharge particle size via grate bars and reducing hammer wear in the crushing chamber, the hammer's service life is extended by 4-6 times. This represents a major breakthrough in crushing technology, truly achieving twice the result with half the effort.

3.Our company's hammer crushers are equipped with the finest components, especially in the selection of wear-resistant parts. The use of alloy hammers represents the most advanced technology and the most wear-resistant metal parts currently available in China.

4.The crusher can process wet materials. During the crushing of mixed materials, water can be added to reduce dust pollution, protecting workers' health and the environment.

TECHNICAL SPECIFICATIONS

| Model | Maximum feed size(mm) |

Average discharge size(mm) |

Capacity(t/h) | Motor power (kw) |

Overall dimensions (mm) |

|

| Cement clinker | Limestone | |||||

| PCX-8040 | 60 | 3 | 15~20 | 20~25 | 45 | 1400×1510×1390 |

| PCX-8080 | 60 | 3 | 25~30 | 30~40 | 55 | 1400×1910×1390 |

| PCX-9010 | 60 | 3 | 45~50 | 50~55 | 75 | 1755×2180×1660 |

| PCX-1010 | 60 | 3~5 | 50~60 | 60~70 | 90 | 2140×2590×2025 |

| PCX-1212 | 60 | 3~5 | 90~100 | 90~110 | 132 | 2525×2870×2325 |

| PCX-1414 | 60 | 5~8 | 110~150 | 120~160 | 200 | 2550×3120×2670 |

| PCX-1616 | 60 | 5~8 | 170~210 | 210~260 | 250 | 2925×3565×2900 |

| PCX-1818 | 60 | 8~10 | 250~270 | 280~310 | 315 | 3125×3755×3150 |

APPLICATION CASES

锤式破碎机.png)

高效锤式破碎机1.png)

高效锤式破碎机3.png)

高效锤式破碎机1.png)

高效锤式破碎机1.png)