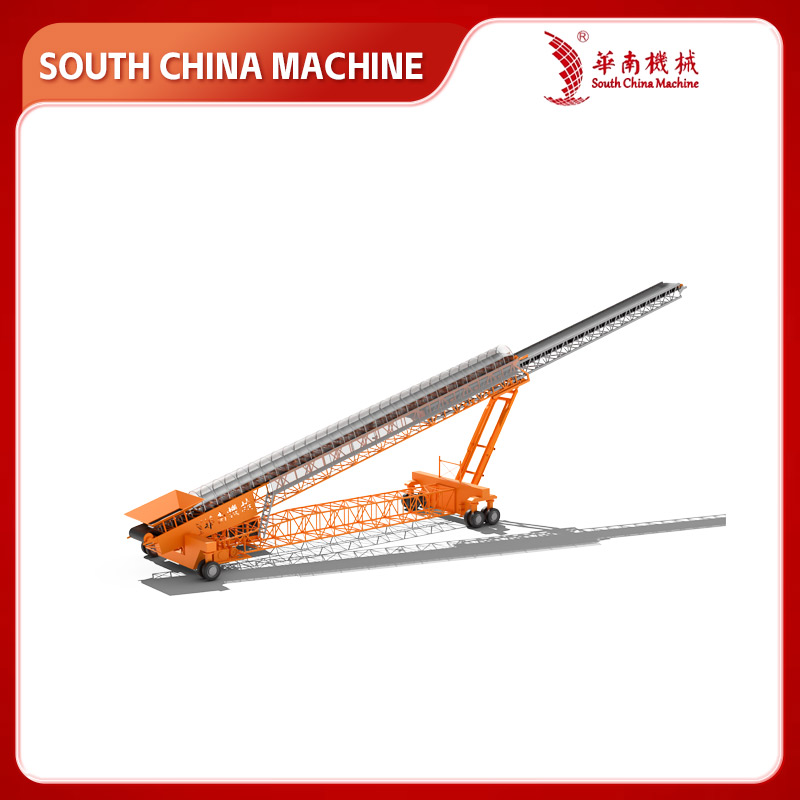

DTII(A) Belt Conveyor

DTII(A) belt conveyor is also called belt conveyor or rubber belt conveyor. It is a conveying equipment with large conveying capacity, simple structure, convenient maintenance, low cost and strong versatility. It is an upgraded product of the two major series, TD75 and DX, and is an indispensable economical conveying equipment for forming rhythmic assembly lines. The products are divided into light, medium and heavy-duty types.

Compared with the TD75 type, the product has been greatly improved and enhanced in terms of material, process, precision, conveying capacity, reliability, etc. The DTII(A) belt conveyor can be transported by a single machine or multiple machines according to the requirements of the conveying process, and can also be transported with a conveying system composed of other conveyors.

Other names:

The DTII(A) belt conveyor can be abbreviated as belt conveyor, transmission belt, conveyor belt, or conveying machine. It is also called DTII(A) fixed belt conveyor, DTII(A) fixed rubber belt conveyor, DTII(A) fixed conveyor, DTII(A) rubber belt conveyor, or DTII(A) belt conveyor.

Application scenarios:

The DTII(A) belt conveyor is widely used in various industries such as metallurgy, mining, coal, ports, power plants, building materials, chemicals, light industry, and petroleum to transport bulk materials or packaged goods.

The working environment temperature suitable for DTII(A) fixed belt conveyor is -20~ +40°C. For DTII belt conveyors working in special environments that require heat resistance, cold resistance, waterproof, anti-corrosion, explosion-proof, flame retardant and other conditions, corresponding protective measures should be taken separately. The DTII(A) fixed belt conveyor is designed according to component series. Designers can select and design according to different terrains and working conditions based on the conveying process requirements, and assemble them into a complete conveyor. This series of components can meet the requirements of horizontal and inclined conveying, and can also adopt conveying forms combining convex arc, concave arc and straight sections.

PRODUCT FEATURES

1.Reliable operation, suitable for important occasions requiring continuous operation;

2.Long conveying distance, large conveying capacity, easy to achieve automation and centralized control;

3.Almost no relative movement between the material and the conveyor belt, low running resistance and low power consumption;

4.Low wear and crushing rate of cargo, which is beneficial to reducing production costs.

PRODUCT SPECIFICATIONS

Belt width series:

DTII(A) fixed belt conveyor takes its belt width as the main parameter, as shown in the following table. Its belt width series complies with the provisions of "Belt Conveyor" (GB/T10595-2017) regarding the basic parameters and dimensions of belt conveyors.

| Belt Width /mm | 400 | 500 | 650 | 800 | 1000 | 1200 |

| Code | 40 | 50 | 65 | 80 | 100 | 120 |

| Belt Width /mm | 1400 | 1600 | 1800 | 2000 | (2200) | (2400) |

| Code | 140 | 160 | 180 | 200 | 220 | 240 |

TECHNICALSPECIFICATIONS

| No. | Conveyor Code DTII(A) | Belt Width /mm | Drive Drum Diameter /mm | Drive Drum Allowable Torque /kN·m | No. | Conveyor Code DTII(A) | Belt Width /mm | Drive Drum Diameter /mm | Drive Drum Allowable Torque /kN·m | No. | Conveyor Code DTII(A) | Belt Width /mm | Drive Drum Diameter /mm | Drive Drum Allowable Torque /kN·m |

| 1 | 4025-1 | 400 | 250 | 0.63 | 57 | 100100-6 | 1000 | 1000 | 66 | 113 | 16080-3 | 1600 | 800 | 40 |

| 2 | 4032-1 | 315 | 0.63 | 58 | 100125-1 | 1250 | 52 | 114 | 16080-4 | 52 | ||||

| 3 | 4032-2 | 1.0 | 59 | 100125-2 | 66 | 115 | 16080-5 | 66 | ||||||

| 4 | 4040-1 | 400 | 1.0 | 60 | 100125-3 | 80 | 116 | 160100-1 | 1000 | 27 | ||||

| 5 | 4040-2 | 1.6 | 61 | 100125-4 | 120 | 117 | 160100-2 | 40 | ||||||

| 6 | 5025-1 | 500 | 250 | 0.63 | 62 | 100140-1 | 1400 | 66 | 118 | 160100-3 | 52 | |||

| 7 | 5032-1 | 315 | 0.63 | 63 | 100140-2 | 120 | 119 | 160100-4 | 66 | |||||

| 8 | 5032-2 | 1.0 | 64 | 100140-3 | 160 | 120 | 160100-5 | 80 | ||||||

| 9 | 5040-1 | 400 | 1.25 | 65 | 100160-1 | 1600 | 120 | 121 | 160100-6 | 120 | ||||

| 10 | 5040-2 | 2.0 | 66 | 100160-2 | 160 | 122 | 160125-1 | 1250 | 66 | |||||

| 11 | 5050-1 | 500 | 1.6 | 67 | 12050-1 | 1200 | 500 | 6.3 | 123 | 160125-2 | 80 | |||

| 12 | 5050-2 | 2.7 | 68 | 12063-1 | 630 | 12 | 124 | 160125-3 | 120 | |||||

| 13 | 6532-1 | 650 | 315 | 1.25 | 69 | 12063-2 | 20 | 125 | 160125-4 | 160 | ||||

| 14 | 6540-1 | 400 | 1.25 | 70 | 12080-1 | 800 | 12 | 126 | 160140-1 | 1400 | 80 | |||

| 15 | 6540-2 | 2.0 | 71 | 12080-2 | 20 | 127 | 160140-2 | 120 | ||||||

| 16 | 6550-1 | 500 | 3.5 | 72 | 12080-3 | 27 | 128 | 160140-3 | 160 | |||||

| 17 | 6550-2 | 6.3 | 73 | 12080-4 | 40 | 129 | 160160-1 | 1600 | 80 | |||||

| 18 | 6563-1 | 630 | 4.1 | 74 | 12080-5 | 52 | 130 | 160160-2 | 120 | |||||

| 19 | 6563-2 | 7.3 | 75 | 120100-1 | 1000 | 12 | 131 | 160160-3 | 160 | |||||

| 20 | 8032-1 | 800 | 315 | 1.25 | 76 | 120100-2 | 20 | 132 | 18080-1 | 1800 | 800 | 20 | ||

| 21 | 8040-1 | 400 | 1.25 | 77 | 120100-3 | 27 | 133 | 18080-2 | 27 | |||||

| 22 | 8040-2 | 2.0 | 78 | 120100-4 | 40 | 134 | 18080-3 | 40 | ||||||

| 23 | 8050-1 | 500 | 2.5 | 79 | 120100-5 | 52 | 135 | 18080-4 | 80 | |||||

| 24 | 8050-2 | 4.1 | 80 | 120100-6 | 66 | 136 | 18080-5 | 120 | ||||||

| 25 | 8063-1 | 630 | 6.0 | 81 | 120100-7 | 80 | 137 | 180100-1 | 1000 | 40 | ||||

| 26 | 8063-2 | 12 | 82 | 120125-1 | 1250 | 52 | 138 | 180100-2 | 52 | |||||

| 27 | 8063-3 | 20 | 83 | 120125-2 | 66 | 139 | 180100-3 | 66 | ||||||

| 28 | 8080-1 | 800 | 7 | 84 | 120125-3 | 80 | 140 | 180100-4 | 80 | |||||

| 29 | 8080-2 | 12 | 85 | 120125-4 | 120 | 141 | 180100-5 | 120 | ||||||

| 30 | 8080-3 | 20 | 86 | 120140-1 | 1400 | 80 | 142 | 180125-1 | 1250 | 66 | ||||

| 31 | 8080-4 | 32 | 87 | 120140-2 | 120 | 143 | 180125-2 | 80 | ||||||

| 32 | 80100-1 | 1000 | 12 | 88 | 120140-3 | 160 | 144 | 180125-3 | 120 | |||||

| 33 | 80100-2 | 20 | 89 | 120160-1 | 1600 | 120 | 145 | 180140-1 | 1400 | 80 | ||||

| 34 | 80100-3 | 32 | 90 | 120160-2 | 160 | 146 | 180140-2 | 120 | ||||||

| 35 | 80100-4 | 40 | 91 | 14080-1 | 1400 | 800 | 20 | 147 | 180140-3 | 160 | ||||

| 36 | 80100-5 | 52 | 92 | 14080-2 | 27 | 148 | 180160-1 | 1600 | 120 | |||||

| 37 | 80100-6 | 66 | 93 | 14080-3 | 40 | 149 | 180160-2 | 160 | ||||||

| 38 | 80125-1 | 1250 | 52 | 94 | 14080-4 | 52 | 150 | 20080-1 | 2000 | 800 | 20 | |||

| 39 | 80125-2 | 66 | 95 | 14080-5 | 66 | 151 | 20080-2 | 27 | ||||||

| 40 | 80125-3 | 80 | 96 | 140100-1 | 1000 | 20 | 152 | 20080-3 | 40 | |||||

| 41 | 80125-4 | 120 | 97 | 140100-2 | 27 | 153 | 20080-4 | 52 | ||||||

| 42 | 10040-1 | 1000 | 400 | 2.5 | 98 | 140100-3 | 40 | 154 | 20080-5 | 66 | ||||

| 43 | 10050-1 | 500 | 3.5 | 99 | 140100-4 | 52 | 155 | 200100-1 | 1000 | 40 | ||||

| 44 | 10050-2 | 6.3 | 100 | 140100-5 | 66 | 156 | 200100-2 | 52 | ||||||

| 45 | 10063-1 | 630 | 6 | 101 | 140100-6 | 80 | 157 | 200100-3 | 66 | |||||

| 46 | 10063-2 | 12 | 102 | 140125-1 | 1250 | 52 | 158 | 200100-4 | 80 | |||||

| 47 | 10080-1 | 800 | 12 | 103 | 140125-2 | 66 | 159 | 200100-5 | 120 | |||||

| 48 | 10080-2 | 20 | 104 | 140125-3 | 80 | 160 | 200125-1 | 1250 | 66 | |||||

| 49 | 10080-3 | 27 | 105 | 140125-4 | 120 | 161 | 200125-2 | 80 | ||||||

| 50 | 10080-4 | 40 | 106 | 140140-1 | 1400 | 80 | 162 | 200125-3 | 120 | |||||

| 51 | 10080-5 | 52 | 107 | 140140-2 | 120 | 163 | 200140-1 | 1400 | 80 | |||||

| 52 | 100100-1 | 1000 | 12 | 108 | 140140-3 | 160 | 164 | 200140-2 | 120 | |||||

| 53 | 100100-2 | 20 | 109 | 140160-1 | 1600 | 120 | 165 | 200140-3 | 160 | |||||

| 54 | 100100-3 | 27 | 110 | 140160-2 | 160 | 166 | 200160-1 | 1600 | 120 | |||||

| 55 | 100100-4 | 40 | 111 | 16080-1 | 1600 | 800 | 20 | 167 | 200160-2 | 160 | ||||

| 56 | 100100-5 | 52 | 112 | 16080-2 | 27 | |||||||||

APPLICATION CASES

TDY带式输送机√.png)

皮带输送机1.png)