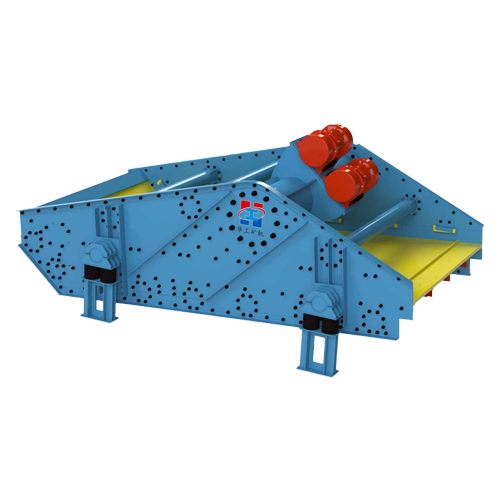

Dewatering screens are used for fine dry and wet screening, dehydration, desliming, and dewatering in coal preparation, mineral processing, chemical industries, and other sectors. They feature a reasonable structure, durability, low noise, and ease of maintenance. They can be applied in sand and gravel washing plants, coal slime recovery in coal preparation plants, dry tailings discharge in mineral processing plants, etc., thus also known as sand and gravel dewatering screens, mining dewatering screens, coal slime dewatering screens, tailings dewatering screens, high-frequency dewatering screens, etc.

When selecting and ordering, it is necessary to specify the screen structure (woven, punched, slotted), mesh size, processing capacity, material name, and feed particle size.

Operating Principle:

The material is evenly fed into the screen inlet by the feed box (or cyclone). Approximately 1/3 of the moisture is removed on the pre-dehydration screen plate installed at a 45° angle to the horizontal. After entering the junction of the flat screen plate and the inclined screen plate, the material accumulates, and the material particles settle by gravity, forming a relatively thin filter layer, which prevents other particles from passing through the screen, causing the filter layer to gradually thicken.

Water that cannot pass through the screen forms a pool above the filter layer. Due to the thinner filter layer here, the moisture gradually escapes under intense movement. The high-frequency vibration compacts the particles such as tailings that form the filter layer, vibrating them towards the discharge port. The material forms a filter cake, and the moisture in the material is partially removed from the screen surface, while the rest adheres to the surface of the material layer due to capillary action. Since the screen surface is installed at a negative inclination, water does not overflow from the discharge port but flows towards the pool at the junction, thereby completing the material dehydration process.

Product Performance Characteristics:

-

High operating frequency, high vibration intensity, low moisture content in the screened product, and high processing capacity.

-

The power source adopts vibration motors, eliminating bearings, coupling, and other vulnerable parts, resulting in a simple structure, easy installation and maintenance, low maintenance costs, and the ability to operate continuously for 24 hours.

-

The pre-dehydration screen plate is installed at a 45° angle to the horizontal, and the dehydration screen plate is installed at a negative inclination, increasing the dehydration area and prompting the material to dehydrate and form a filter layer as soon as possible.

-

The connection between the side plates, crossbeams, motor bases, and reinforcing plates adopts torsion shear type G high-strength bolts without welds, avoiding side plate cracking issues caused by welding.

-

The screen plate adopts polyurethane material with a high opening rate and good water permeability.

-

Small screens use rubber springs for vibration isolation, reducing noise and providing good vibration damping effects, lowering the dynamic load on the foundation. Large screens use high-manganese steel springs for good elasticity.

QSTS Series dewatering screen

| Model | Power(kw) | Number of vibrating motors |

Processing volume (t/h) | Feeder particle size(mm) |

specifications(mm) | Sieve plate area(m²) |

Sieve plate material | Total weight(kg) | Exterior size(mm) |

| QSTS-0918 | 1.1 | 2 | 10-30 | ≤10 | 900×1800 | 1.6 | polyurethane | 600 | 1885×1290×1077 |

| QSTS-0924 | 1.1 | 10-30 | 900×2400 | 2.2 | 850 | 2483×1290×1215 | |||

| QSTS-1224 | 2.2 | 1200×2400 | 2.88 | 1100 | 2485×1590×1424 | ||||

| QSTS-1230 | 2.2 | 30-60 | 1200×3000 | 3.6 | 1225 | 3084×1590×1439 | |||

| QSTS-1236 | 3 | 30-60 | 1200×3600 | 4.32 | 1468 | 3677×1590×1498 | |||

| QSTS-1530 | 3 | 60-100 | 1500×3000 | 4.5 | 1357 | 3083×1890×1433 | |||

| QSTS-1536 | 3 | 60-100 | 1500×3600 | 5.4 | 1750 | 3683×1890×1445 | |||

| QSTS-1836 | 5.5 | 100-130 | 1800×3600 | 6.48 | 3030 | 3717×2423×1927 | |||

| QSTS-1842 | 5.5 | 100-130 | 1800×4200 | 7.56 | 3434 | 4368×2421×2104 |

HS-T脱水筛.png)

微信截图_20220623132704.png)