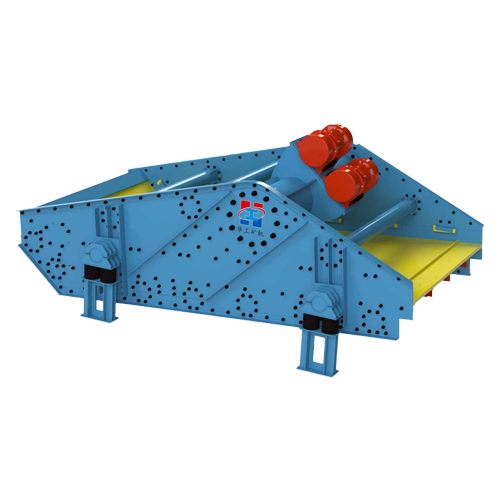

Principle Overview

Xinhai Company has many unique features in the design of dehydration screens. The screening surface is designed as a segmented structure, with the first section inclined at a 5 ° angle to the horizontal plane, so that the discharge end is higher than the feeding end. The second paragraph forms a 45 ° angle with the horizontal plane, greatly improving the dehydration effect. The vibration motor has a small amplitude and high frequency, making the operation of the sieve very stable. The screen mesh is embedded for easy installation and local replacement. The combination of Xinhai dewatering screen, Xinhai XCII and XCIII hydrocyclones (see the classification equipment section of this manual), and Xinhai high-efficiency deep cone concentrator results in better dewatering effect, larger overall processing capacity, more complete dewatering, and more significant economic benefits.

Domestic siliceous raw material production plants have achieved unexpected results by using Xinhai dewatering screens. For example, Anhui Tongda Quartz Sand Mine and Fujian Mingda Silica Sand Mine use Xinhai hydrocyclones and Xinhai dewatering screens for product dewatering, which can reduce the water content of their products to about 10%, and operate smoothly with a low failure rate.

Equipment features

- The overall riveted screen box has high strength, good rigidity, and no thermal stress;

- Modular sieve plate and sealing strip installation form, with good sealing effect;

- The contact area with the material is covered with wear-resistant natural rubber, which is corrosion-resistant and wear-resistant;

- Post installed low concentration slurry overflow pipe to accelerate dehydration speed;

- The -5 ° inclined screen surface reduces the moisture content of the material discharged from the screen;

- The wear-resistant rubber shock absorber makes the sieve run more smoothly and persistently.

Scope of use

Dehydration of concentrates and tailings from non-metallic mines such as quartz sand, fluorite ore, and feldspar ore. Dehydration of tailings from metal mines such as gold mines (gold beneficiation plants, coal slurry plants), lead-zinc mines, iron mines, and copper mines.

Technical parameters (dry material t/h)

|

Specification and model |

Minimum solid volume feed concentration of 30% |

Single motor power (kW) x quantity (units) |

||||||

|

Fine coal theoretically -0.5+0.1 (mm) Specific gravity 1.5 |

Coarse sand is approximately -5 (mm) 100%, -0.6 (mm) 50%, specific gravity 2.7 |

Fine sand 90% -1 (mm) Specific gravity 2.7 |

980 (r/min) |

1460 (r/min) |

||||

|

1460 (r/min) |

980 (r/min) |

1460 (r/min) |

980 (r/min) |

1460 (r/min) |

980 (r/min) |

|||

|

VD6 |

6~8 |

10~13 |

14 |

28 |

10 |

21 |

|

2×2 |

|

VD9 |

9~12 |

15~20 |

21 |

42 |

16 |

32 |

3×2 |

|

|

VD12 |

15~19 |

24~30 |

33 |

67 |

25 |

50 |

2.6×2 |

4×2 |

|

VD15 |

30~35 |

50~60 |

63 |

125 |

47 |

94 |

2.4×4 |

2.25×4 |

|

VD18 |

35~45 |

60~80 |

77 |

153 |

57 |

115 |

|

3.7×4 |

|

VD21 |

— |

85~100 |

— |

225 |

— |

164 |

15 |

— |

|

VD24 |

95~110 |

250 |

190 |

|||||

HS-T脱水筛.png)

微信截图_20220623132704.png)