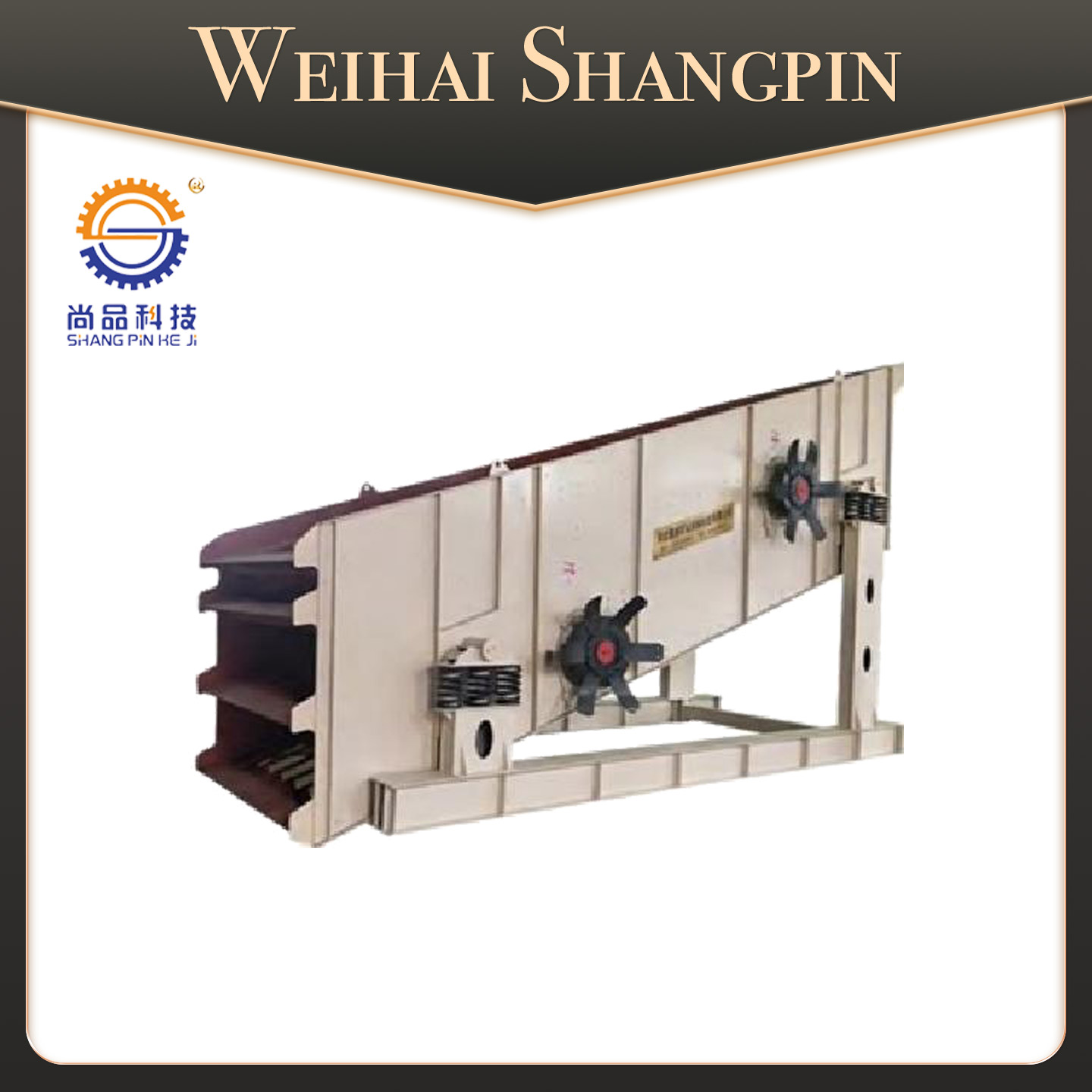

I.Performance Features

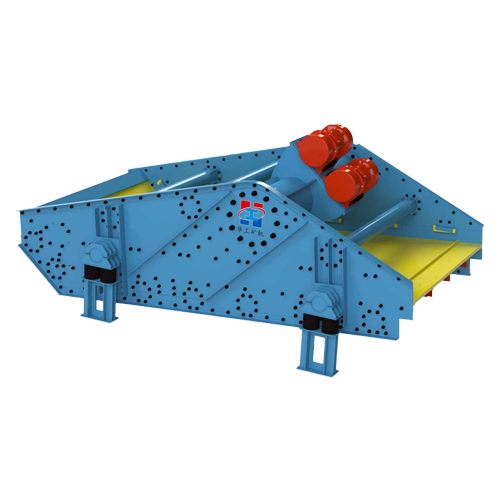

1. The vibration motor with standard configuration is a domestic well-known brand, and imported motors can be selected.

2. The screen machine uses Huck bolt connections. Side plates and protective plates are processed by CNC machines, ensuring reliability and stability during long-term operation, and reducing the workload of maintenance.

3. Both the main beam and bottom support beam are made of manganese steel, and they undergo heat treatment for reduce stress. Non-destructive testing ensures the strength and quality of each beam.

4. The screen plate uses our the self-developed ultra-wear-resistant polyurethane (ZL201520352467.2) screen mesh (Minimum mesh 0.15mm). It employs the most advanced anti-clogging technology to guarantee effective dewatering.

II.Technical Parameter List

|

Model |

Vibration Mode |

Motor Power (Kw) |

Screen Surface Area (m) |

Screen Box Angle |

Screen Mesh Size (mm) |

Screen Mesh Material |

Production Capacity (t/台.h) |

|

STS1025 |

Vibration Motor |

2.4×2 |

2.5 |

1⁰~5° |

0.15-0.5 |

Polyurethane Screen Mesh |

0-5 |

|

STS1230 |

Vibration Motor |

3.0×2 |

3.6 |

1⁰~5° |

0-10 |

||

|

STS1236 |

Vibration Motor |

3.0×2 |

4.32 |

1⁰~5° |

0-20 |

||

|

STS1530 |

Vibration Motor |

4.0×2 |

4.5 |

1⁰~5° |

0-30 |

||

|

STS1536 |

Vibration Motor |

4.0×2 |

5.4 |

1⁰~5° |

0-40 |

||

|

STS1836 |

Vibration Motor |

5.5×2 |

6.48 |

1⁰~5° |

0-60 |

||

|

Vibration Exciter |

7.5×2 |

||||||

|

STS1848 |

Vibration Motor |

5.5×2 |

7.38 |

1⁰~5° |

0-70 |

||

|

Vibration Exciter |

7.5×2 |

||||||

|

STS2145 |

Vibration Motor |

7.5×2 |

9.45 |

1⁰~5° |

0-90 |

||

|

Vibration Exciter |

11×2 |

||||||

|

STS2445 |

Vibration Motor |

7.5×2 |

10.8 |

1⁰~5° |

0-100 |

||

|

Vibration Exciter |

11×2 |

HS-T脱水筛.png)

微信截图_20220623132704.png)