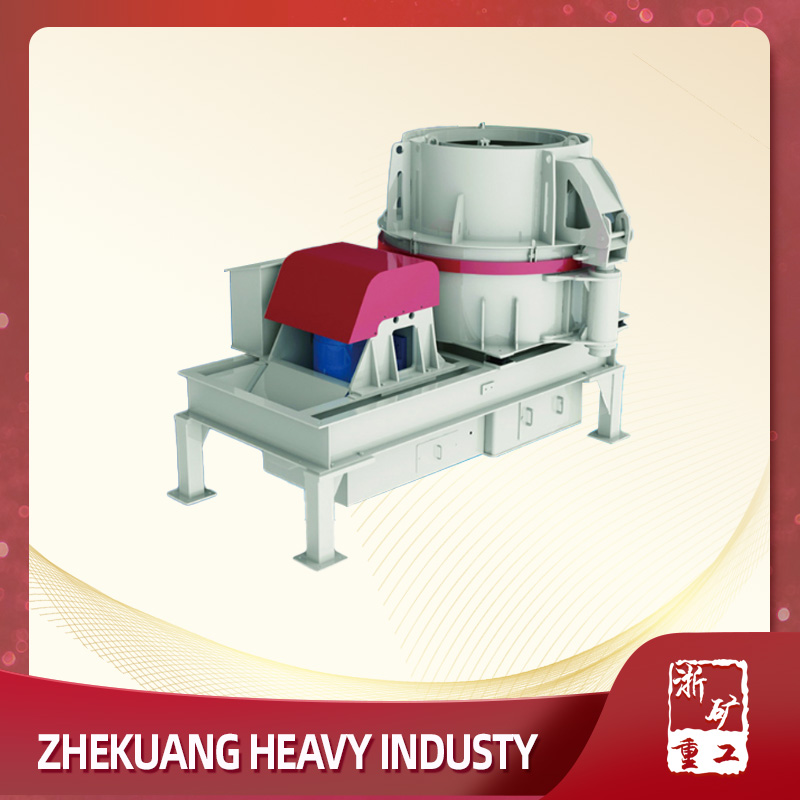

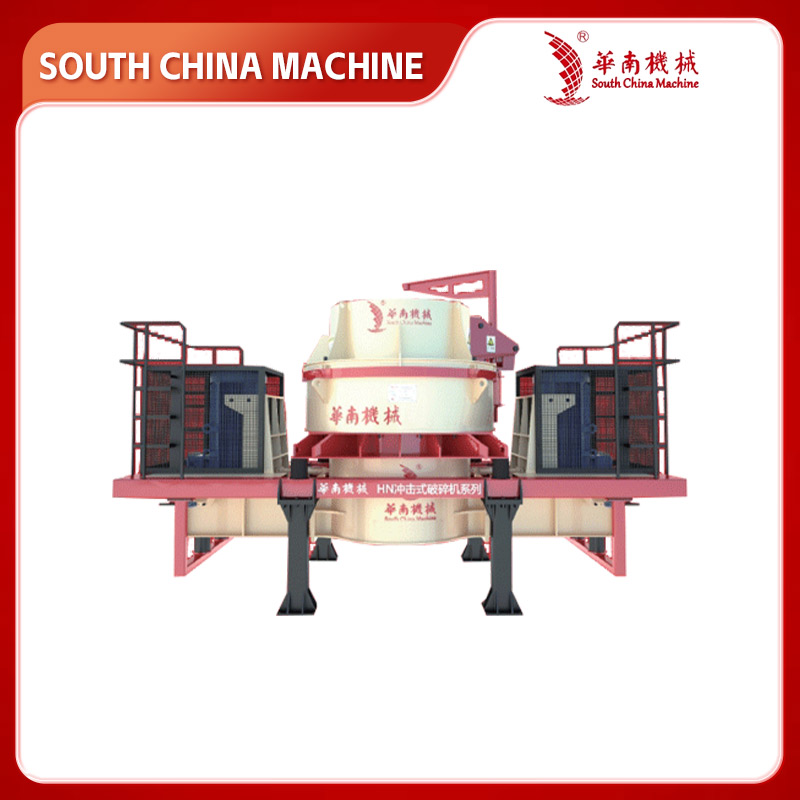

Product Introducion

The VSI vertical impact crusher can provide high-quality sand and gravel aggregates for highways, high-speed railways, high-rise buildings, municipal engineering, hydropower dam construction, and concrete mixing stations. It is the preferred equipment in the field of manual sand making and stone shaping.

Perfomance Characteristics

1. The dual waterfall flow feeding system enhances the particle shape and significantly improves the material throughput capacity;

2. The lining plate of the crushing chamber adopts a columnar design, known as the "impact rod". By rotating the impact rod (up to four times), a new working surface is obtained to continue working, which increases the use of wear-resistant parts and reduces user costs;

3. The unique installation method of the counterattack rod saves time and effort in maintenance;

4. It is less affected by the moisture content of the material, and the moisture content can reach about 30%;

5. Unique deep cavity design, large processing capacity, high sand formation rate, and good particle shape;

6. Choose motors with high protection levels, which have the characteristics of high efficiency and low noise.

Technical Parameter

|

No. |

Specification and model |

Power(kW) |

Feeding method |

Feeding grain size(mm) |

Processing capacity(t/h) |

External dimensions(mm) |

|

1 |

VSI550 |

132 |

Waterfall flow and feed center |

≤35 |

90-280 |

3925×01840×2771 |

|

Full center feeding |

≤35 |

70-150 |

||||

|

2 |

VSI850 |

2×160 |

Waterfall flow and feed center |

≤50 |

215-390 |

4800×02200×2895 |

|

Full center feeding |

≤40 |

150-350 |

||||

|

3 |

VSI1000 |

2×250 |

Waterfall flow and feed center |

≤60 |

320-580 |

5160×02430×3500 |

|

Full center feeding |

≤50 |

225-410 |

||||

|

4 |

VSI1200 |

2×315 |

Waterfall flow and feed center |

≤60 |

410-720 |

5570×02660×3550 |

|

Full center feeding |

≤55 |

380-620 |

8HL.png)