I.Product Performance and Features

1. Maximum capacity: 550 t/h with desliming.

2. Feed size: 110mm-0.25mm.

3. High sorting accuracy: For 0.5mm grade Ep1=0.02-0.04kg/L and Ep2=0.02-0.06Kg/L for 0.5-0.25mm grade Ep≤0.1Kg/L.

4. Depending on the nature of the raw coal and the internal forces, the cyclone can be made in segments using wear-resistant materials like high-alumina ceramics, high-chromium alloy, silicon carbide, etc. Our lining options are available to deliver long wear life in abrasive, high-ash-content refuse applications.

5. It utilizes an adjustment mechanism combining the sizing of the dust collector and the insertion depth of the vortex finder in the secondary DMC, achieving online adjustment of the actual sorting density of the secondary DMC.

II. Main Technical Parameters

|

Model |

Cylinder diameter(mm) |

Maximum particle size (mm) |

Pressure (MPa) |

Capacity (t/h) |

Medium circulation volume (m³/h) |

|

|

First stage |

Second stage |

|||||

|

PTMC 500/350 |

500 |

350 |

20 |

0.06–0.10 |

40–60 |

200-300 |

|

PTMC 600/400 |

600 |

400 |

30 |

0.08–0.12 |

50–80 |

300-400 |

|

PTMC 710/500 |

710 |

500 |

35 |

0.09–0.14 |

70–120 |

400-550 |

|

PTMC 780/550 |

780 |

550 |

40 |

0.10–0.15 |

100–160 |

550-650 |

|

PTMC 850/600 |

850 |

600 |

45 |

0.13–0.16 |

120–180 |

650-750 |

|

PTMC 900/650 |

900 |

650 |

50 |

0.15–0.18 |

140–200 |

750-950 |

|

PTMC 1000/710 |

1000 |

710 |

55 |

0.18–0.22 |

180–240 |

900-1100 |

|

PTMC 1100/780 |

1100 |

780 |

60 |

0.20–0.24 |

220–300 |

1100-1400 |

|

PTMC 1200/850 |

1200 |

850 |

70 |

0.22–0.28 |

300–400 |

1400-1700 |

|

PTMC 1300/920 |

1300 |

920 |

80 |

0.26–0.32 |

350–450 |

1600-1900 |

|

PTMC 1400/1000 |

1400 |

1000 |

100 |

0.30–0.40 |

450–550 |

1900-2300 |

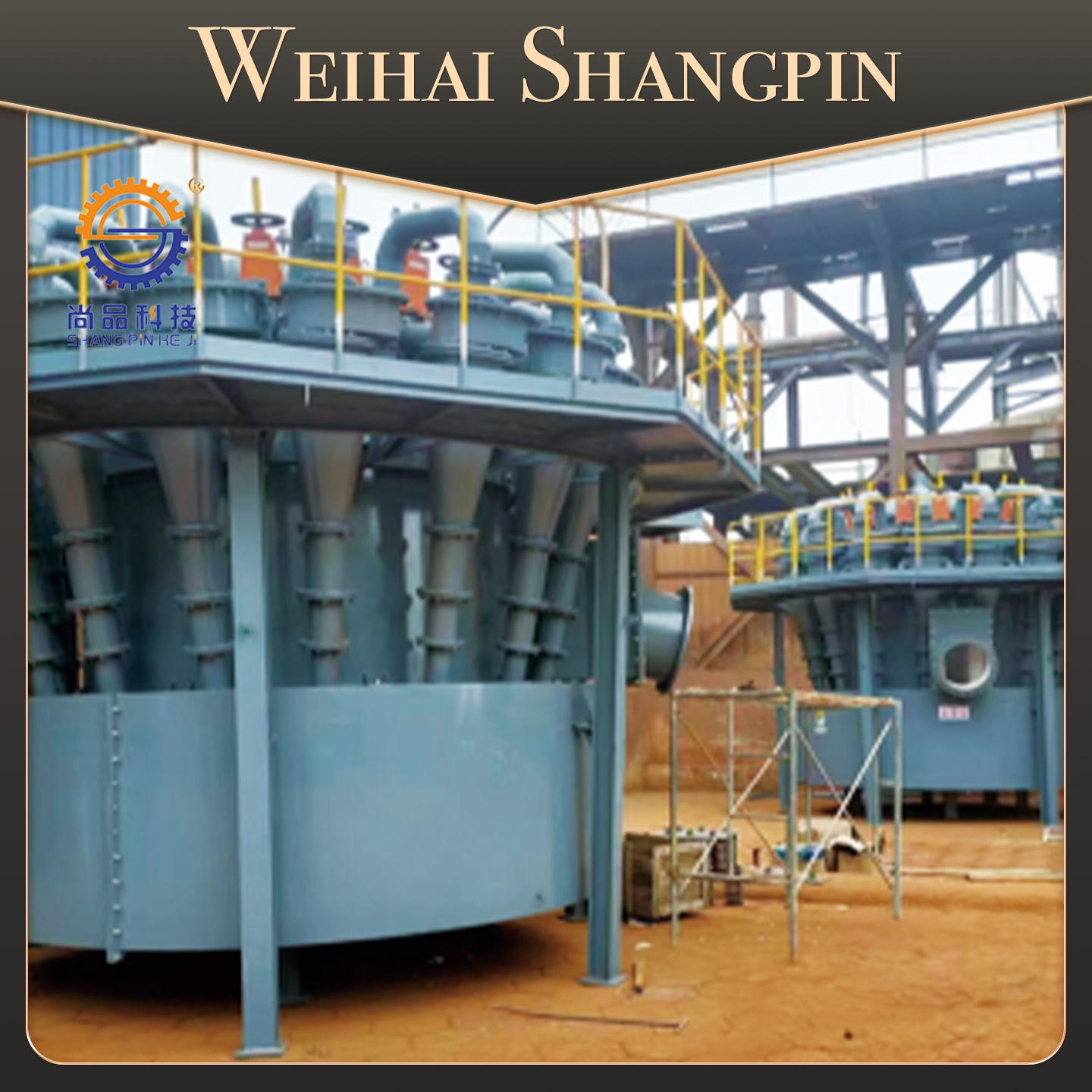

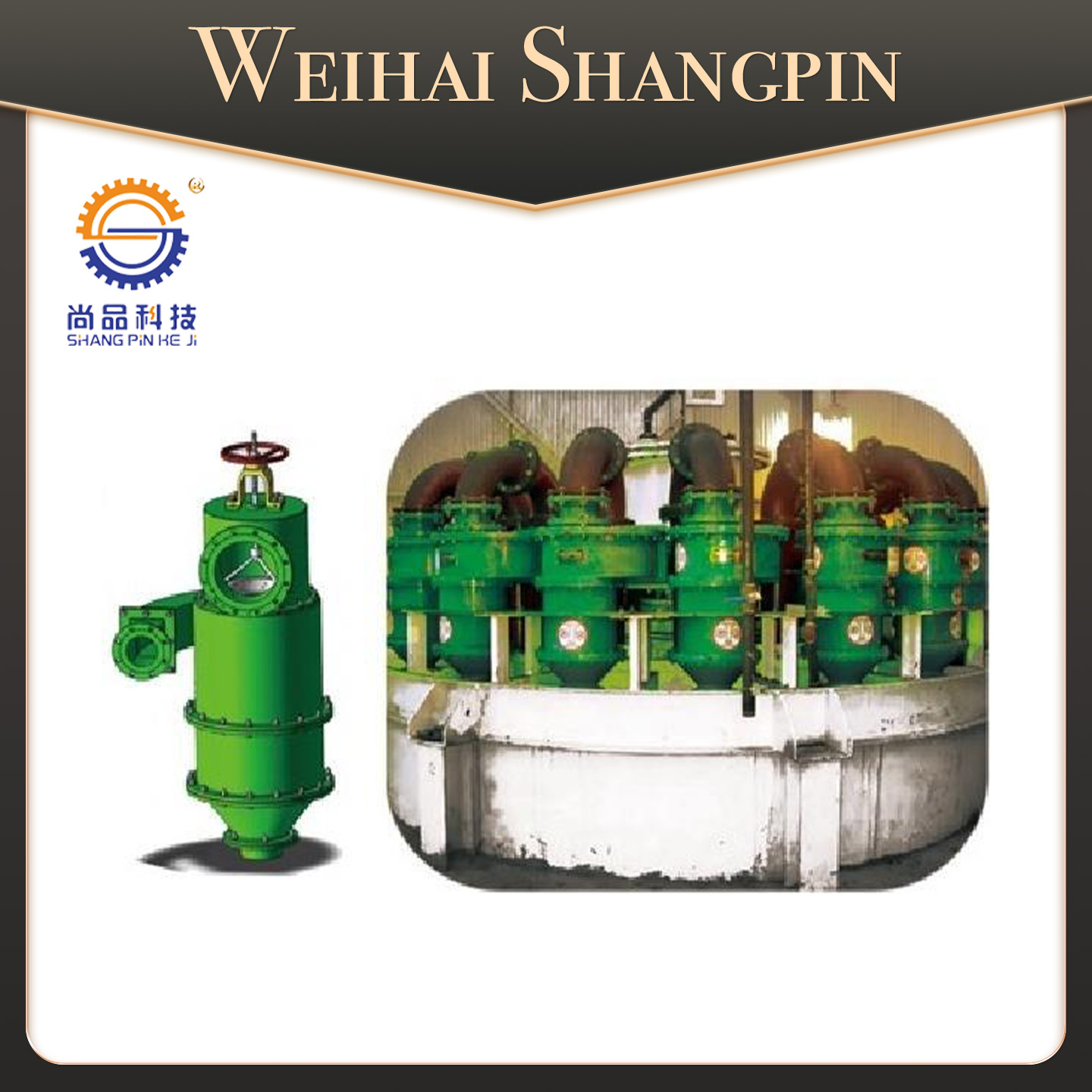

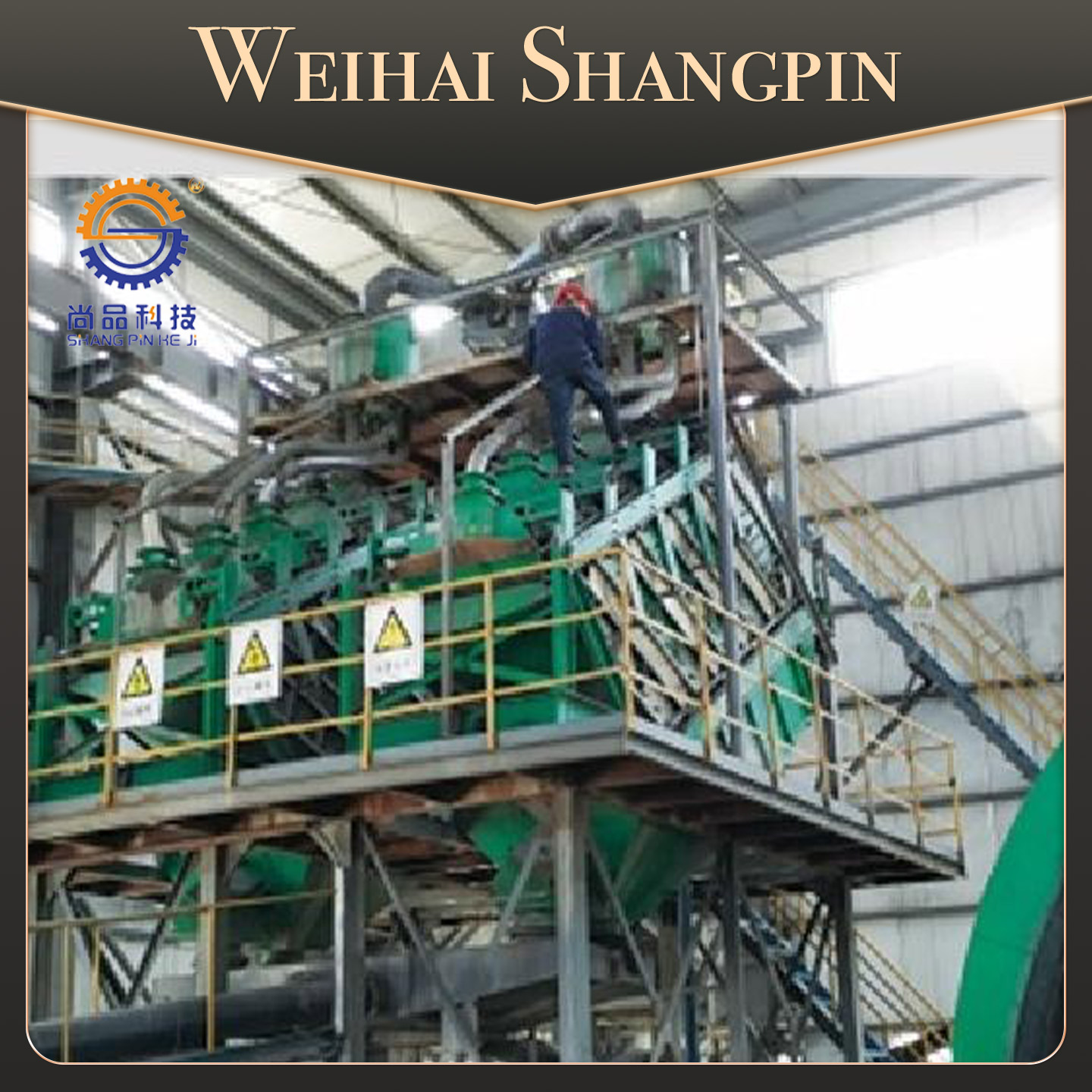

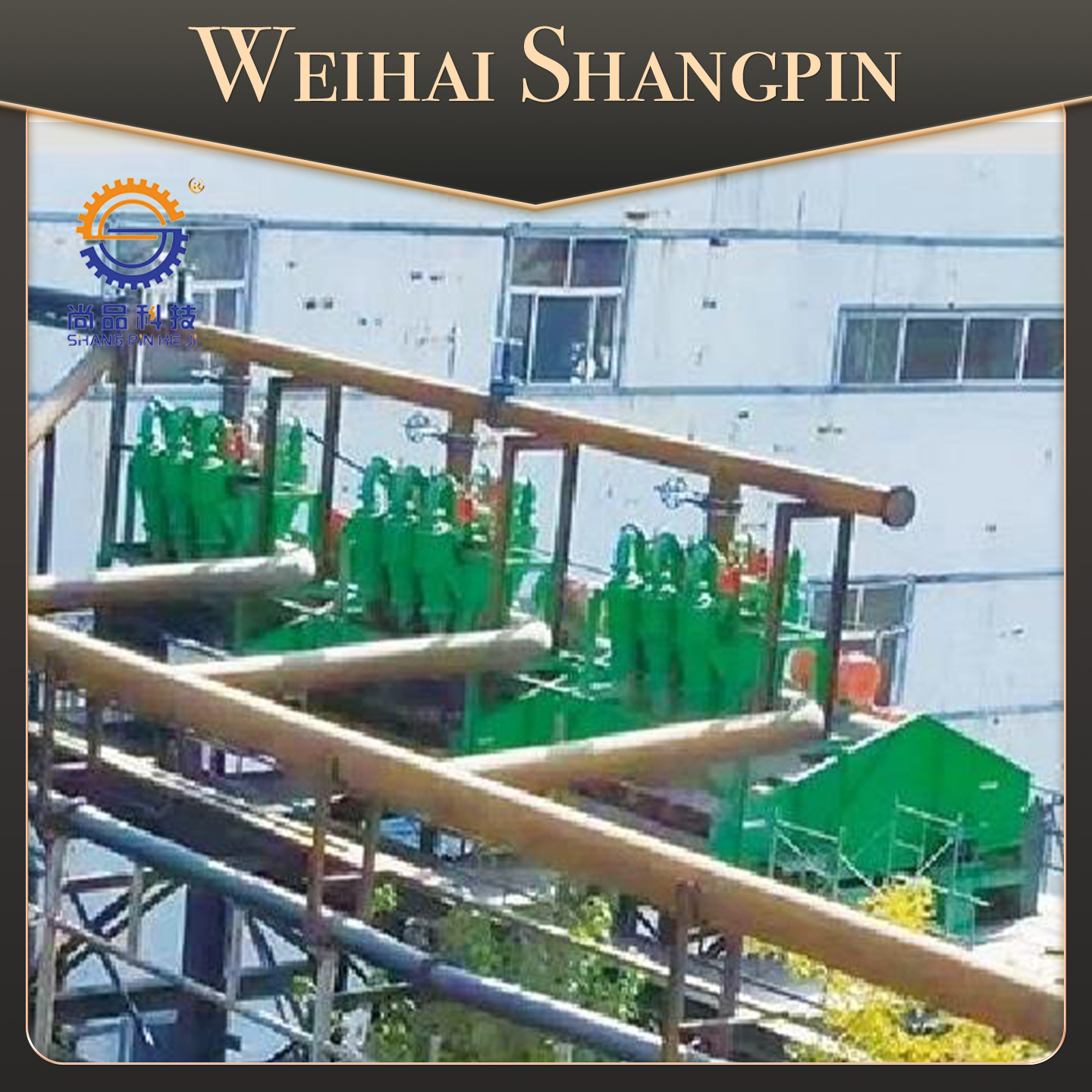

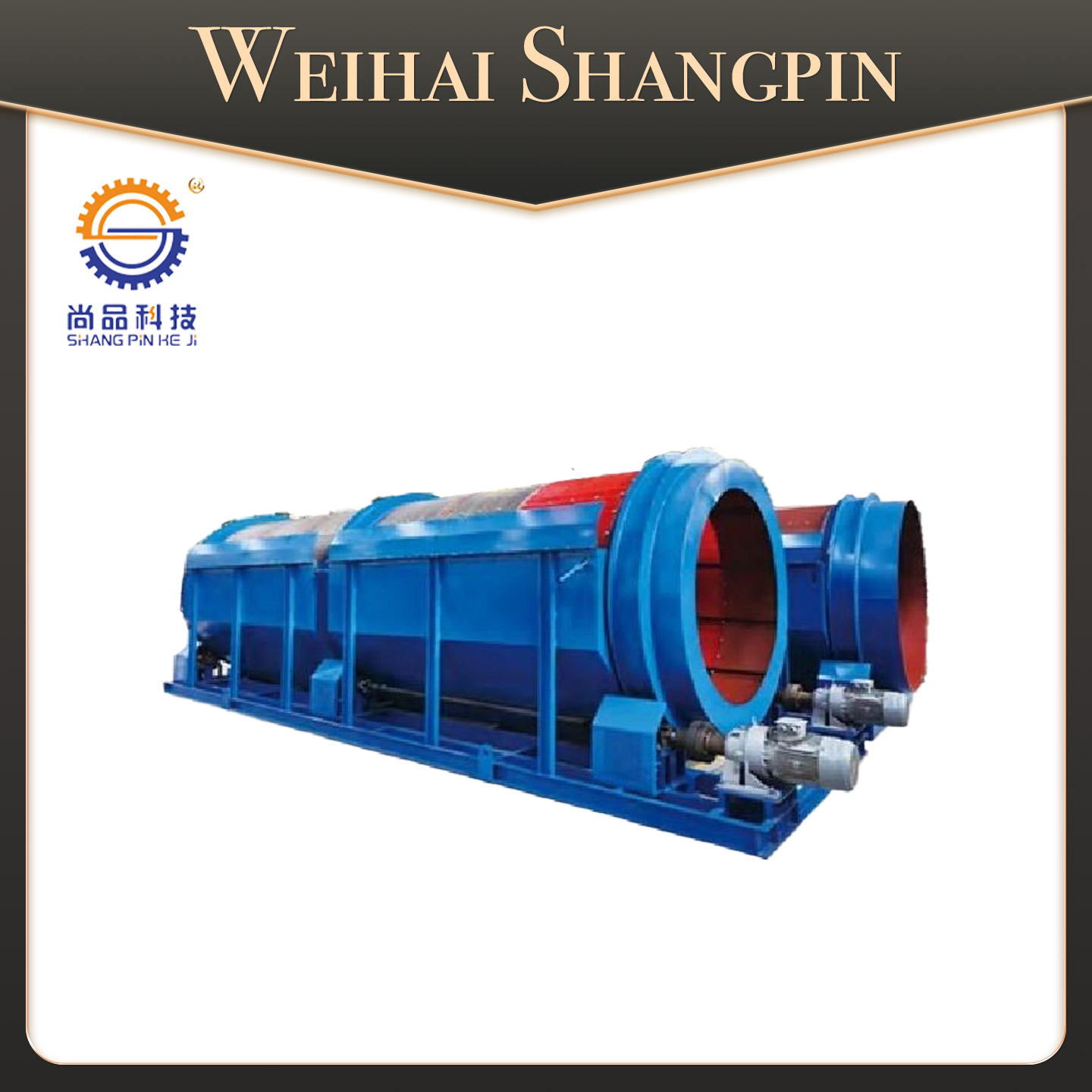

III.Field application examples

微信截图_20220623132149.png)