Principle Overview

Under pressure, the slurry enters the shell through the feed pipe in the involute direction and undergoes rotational motion inside the shell. Coarse or high-density particles in the slurry enter the outer periphery of the rotating flow due to significant centrifugal force, and are ultimately discharged from the bottom settling nozzle to form settling sand; Fine particles experience less centrifugal force and are located at the center of the rotating flow, moving upwards with the liquid flow, and finally discharged through the overflow pipe to become overflow.

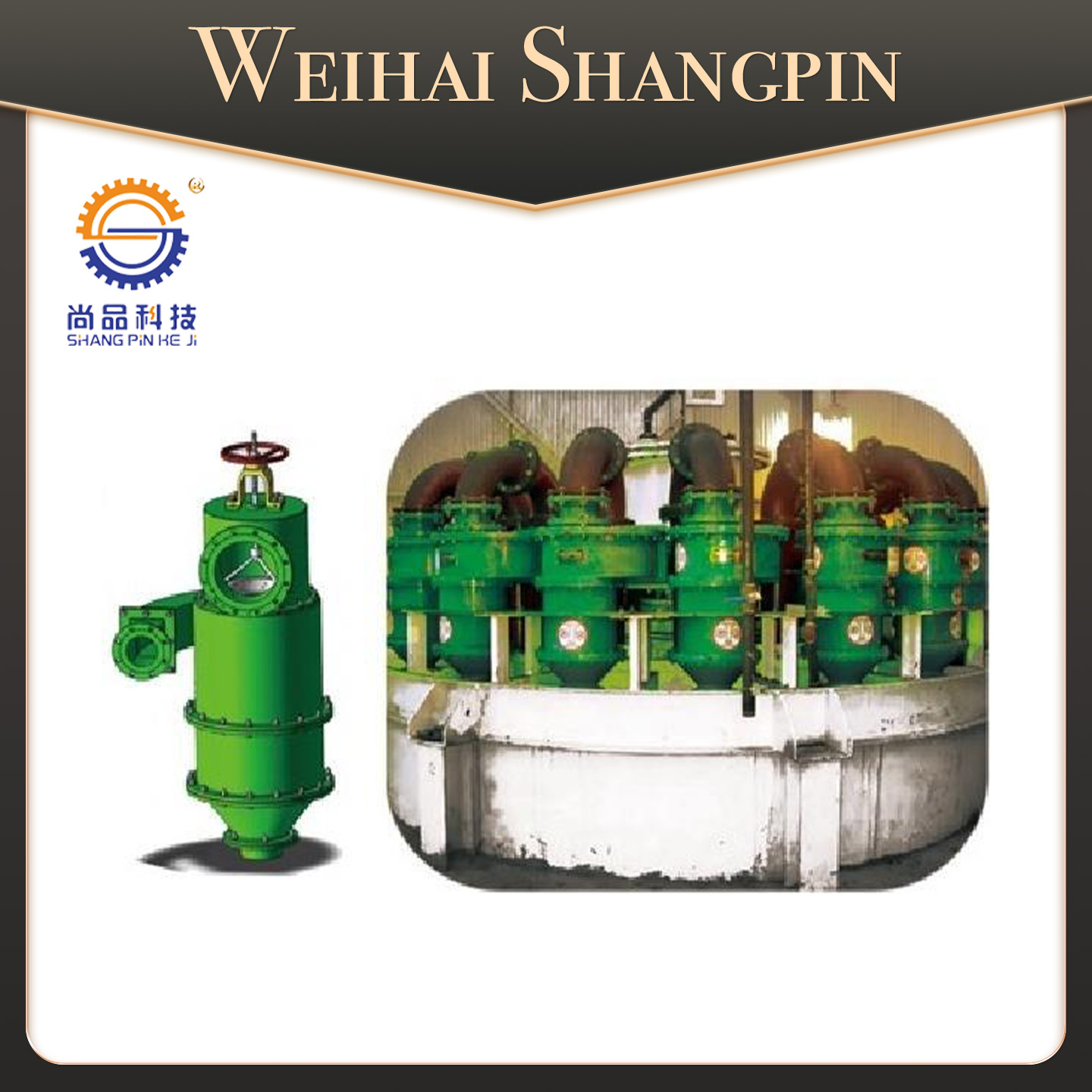

XC II Graded Hydrocyclone

The hydrocyclone developed by Xinhai Company has world advanced level, and its feeding port adopts involute feeding method to feed materials, which is more conducive to increasing the centrifugal force of materials, improving the grading effect, and greatly reducing the wear of the feeding box.

Equipment Features

- Lining wear-resistant rubber molded parts;

- The feeding port adopts the involute feeding method, which reduces the degree of turbulence caused by sudden divergence when the material enters the cyclone, makes the fluid movement in the cyclone tend to be stable, and improves the separation performance of the cyclone;

- The length ratio of the cone section of the cyclone and the insertion depth of the overflow pipe are reasonable, resulting in higher classification efficiency;

- Specially suitable for grading operations, it completely replaces spiral classifiers in medium and large mines and can increase the processing capacity of ball mills by 10% -15%.

XC II Grading Technical Parameters

|

Model |

Specifications |

Processing capacity (m³/h) |

Grading Particle Size (μm) |

Overflow outlet diameter (mm) |

Sand Outlet Diameter (mm) |

Inlet pressure (MPa) |

|

XC II F 150 |

150 |

10~23 |

25~74 |

30~50 |

8~22 |

0.06~0.15 |

|

XC II F 200 |

200 |

17~38 |

28~80 |

40~65 |

16~32 |

|

|

XC II F 250 |

250 |

24~53 |

30~82 |

65~100 |

16~40 |

|

|

XC II F 300 |

300 |

40~100 |

36~90 |

65~120 |

20~40 |

|

|

XC II F 350 |

350 |

56~118 |

40~100 |

80~120 |

30~70 |

|

|

XC II F 375 |

375 |

74~157 |

42~105 |

90~135 |

30~70 |

|

|

XC II F 450 |

450 |

90~192 |

44~110 |

100~150 |

30~70 |

|

|

XC II F 500 |

500 |

128~300 |

50~115 |

130~220 |

35~100 |

|

|

XC II F 550 |

550 |

155~368 |

52~120 |

140~240 |

35~100 |

|

|

XC II F 600 |

600 |

200~468 |

57~125 |

160~260 |

65~110 |

|

|

XC II F 660 |

660 |

237~524 |

60~130 |

180~280 |

80~150 |

Note: Actual parameters may vary depending on the selection results.

XC II Concentrated Hydrocyclone

The latest developed hydraulic cyclone by the company is suitable for tailings dry discharge. Its feeding port structure is unique, the height of the cylindrical section and the angle of the cone section are more reasonable, the insertion depth of the overflow pipe is further optimized, the concentration efficiency is high, the concentration is high, the bottom flow concentration can reach 75%, and the overflow particle size is fine. The effect is significant in the application of tailings dry discharge.

XC II Concentrated Technical Parameters

|

Model |

Specifications |

Processing capacity (m³/h) |

Grading Particle Size (μm) |

Overflow Outlet Diameter (mm) |

Sand Outlet Diameter (mm) |

Inlet pressure (MPa) |

|

XC II N 150 |

150 |

11~17 |

25~74 |

38、45 |

8~22 |

0.08~0.15 |

|

XC II N 200 |

200 |

19~31 |

28~80 |

50、62 |

16~32 |

|

|

XC II N 250 |

250 |

30~47 |

30~82 |

62、75 |

16~40 |

|

|

XC II N 300 |

300 |

43~69 |

36~90 |

75、93 |

20~40 |

|

|

XC II N 350 |

350 |

54~85 |

40~100 |

86、105 |

30~70 |

|

|

XC II N 400 |

400 |

76~120 |

42~105 |

100、119 |

30~70 |

|

|

XC II N 450 |

450 |

89~138 |

44~110 |

100、120 |

30~70 |