I.Product Performance and Features

1. Our large-diameter Heavy-media Cyclones accept larger top size material for efficient cleaning at higher feed rates within your coal preparation plant. Ep≤0.03, η=95%.

2. Depending on the nature of the raw coal and the internal forces, the cyclone can be made in segments using wear-resistant materials like high-alumina ceramics, high-chromium alloy, silicon carbide, etc. Our lining options are available to deliver long wear life in abrasive, high-ash-content refuse applications.

3. It has a wide range of applications, and can be extensively used for sorting high sulfur coal and hard-to-sort or very hard-to-sort coal.

4. Suitable for retrofitting older plants. Re-selection of Jig products (coarse refined coal or medium coal) can increase the recovery rate of refined coal by 3%–5%.

II.Main Technical Parameters

|

Model |

Cylinder diameter(mm) |

Maximum particle size(mm) |

Pressure(MPa) |

Capacity(t/h) |

Medium circulation volume(m³/h) |

|

2PZX 350 |

350 |

20 |

0.06-0.12 |

15-30 |

100-150 |

|

2PZX 500 |

500 |

20 |

0.06-0.12 |

20-40 |

150-300 |

|

2PZX 600 |

600 |

30 |

0.06-0.12 |

40-80 |

250-350 |

|

2PZX 660 |

660 |

30 |

0.06-0.14 |

60-100 |

300-400 |

|

2PZX 710 |

710 |

40 |

0.08-0.14 |

80-140 |

400-600 |

|

2PZX 800 |

800 |

40 |

0.08-0.14 |

120-200 |

600-800 |

|

2PZX 850 |

850 |

50 |

0.08-0.14 |

150-250 |

700-900 |

|

2PZX 900 |

900 |

50 |

0.10-0.16 |

250-350 |

800-1100 |

|

2PZX 1000 |

1000 |

60 |

0.10-0.16 |

300-400 |

1000-1300 |

|

2PZX 1150 |

1150 |

60 |

0.10-0.16 |

350-450 |

1100-1400 |

|

2PZX 1200 |

1200 |

80 |

0.10-0.16 |

400-500 |

1300-1600 |

|

2PZX 1300 |

1300 |

80 |

0.12-0.18 |

450-550 |

1500-1800 |

|

2PZX 1400 |

1400 |

90 |

0.12-0.18 |

500-600 |

1600-2000 |

|

2PZX 1450 |

1450 |

90 |

0.12-0.18 |

550-650 |

1900-2200 |

|

2PZX 1500 |

1500 |

100 |

0.12-0.18 |

650-750 |

2000-2400 |

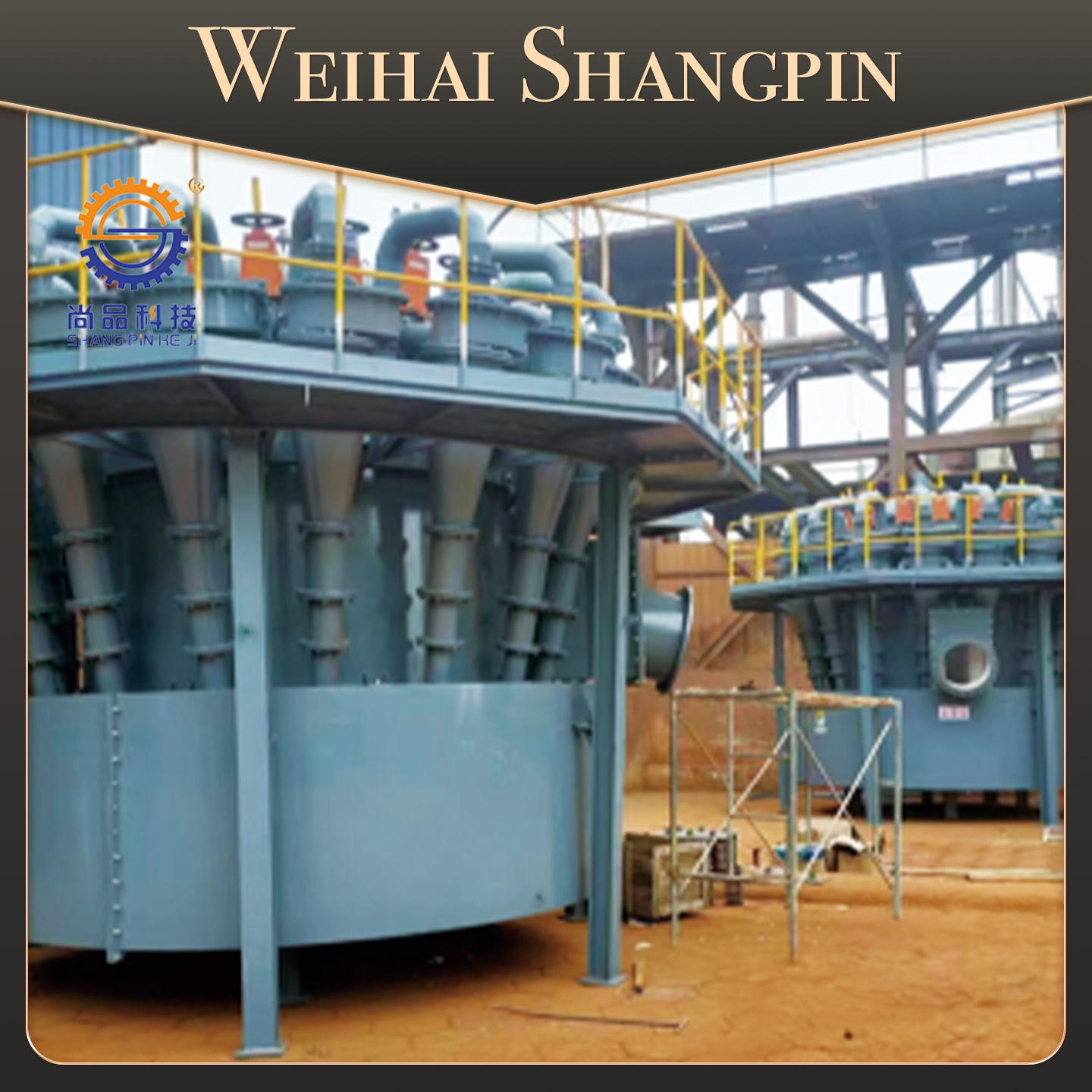

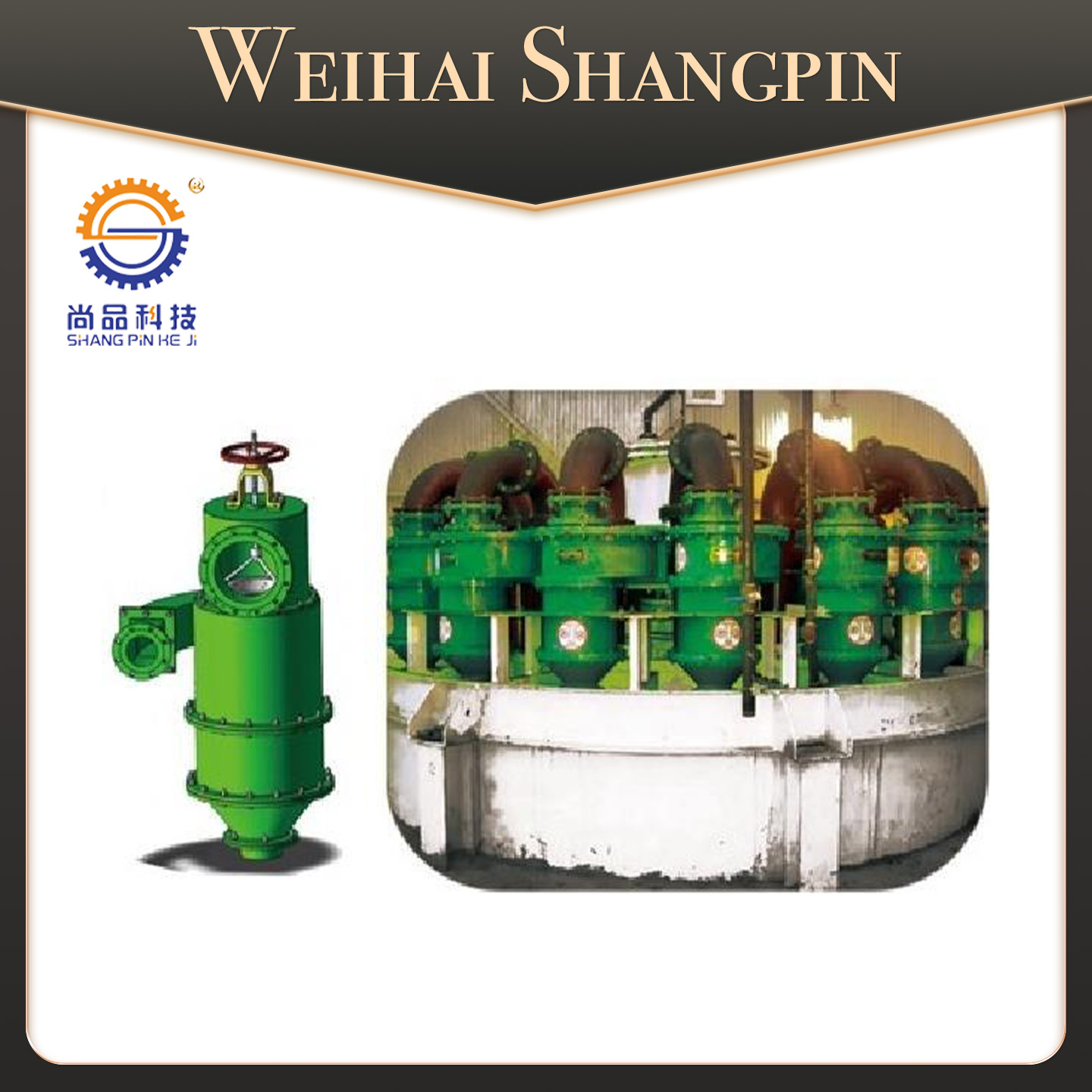

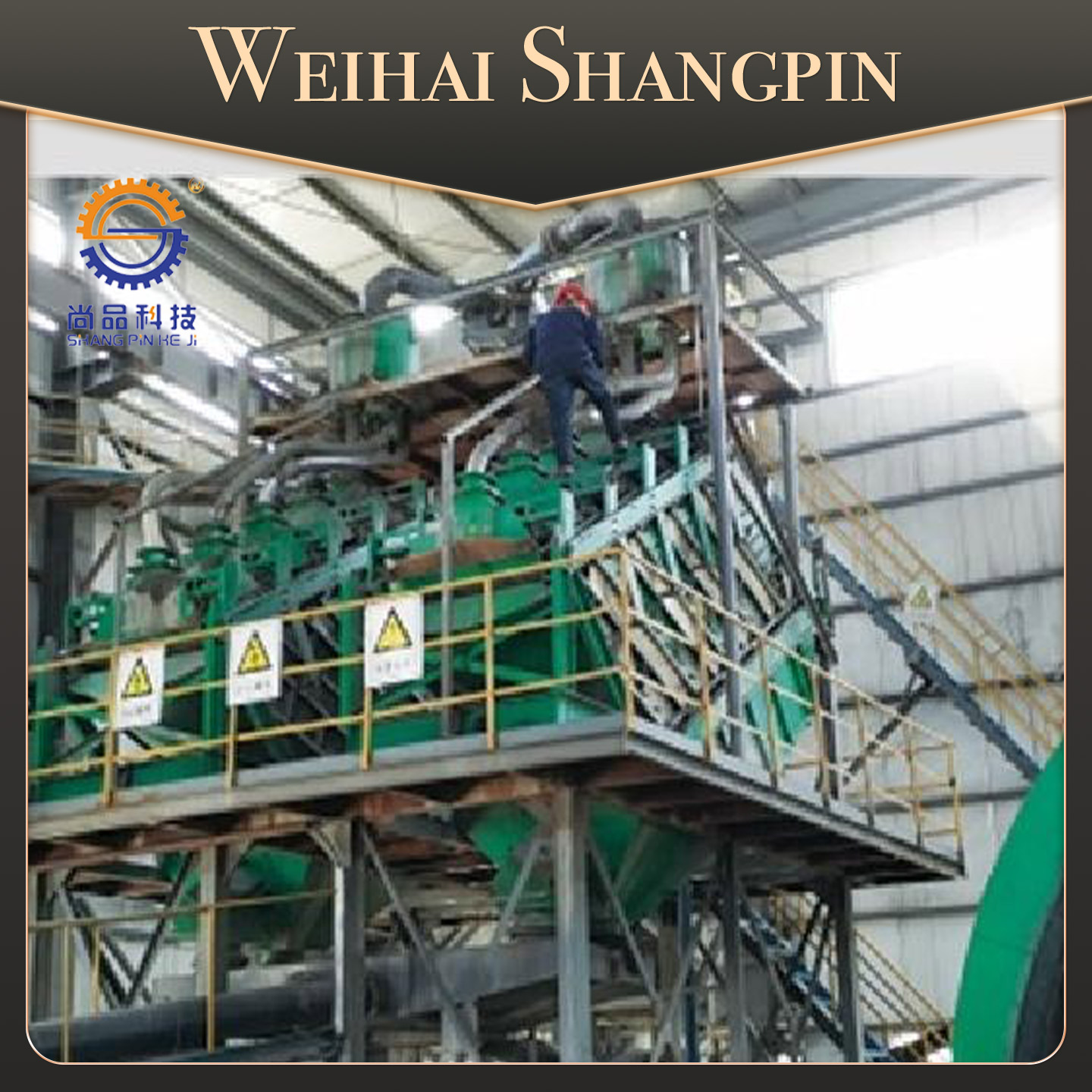

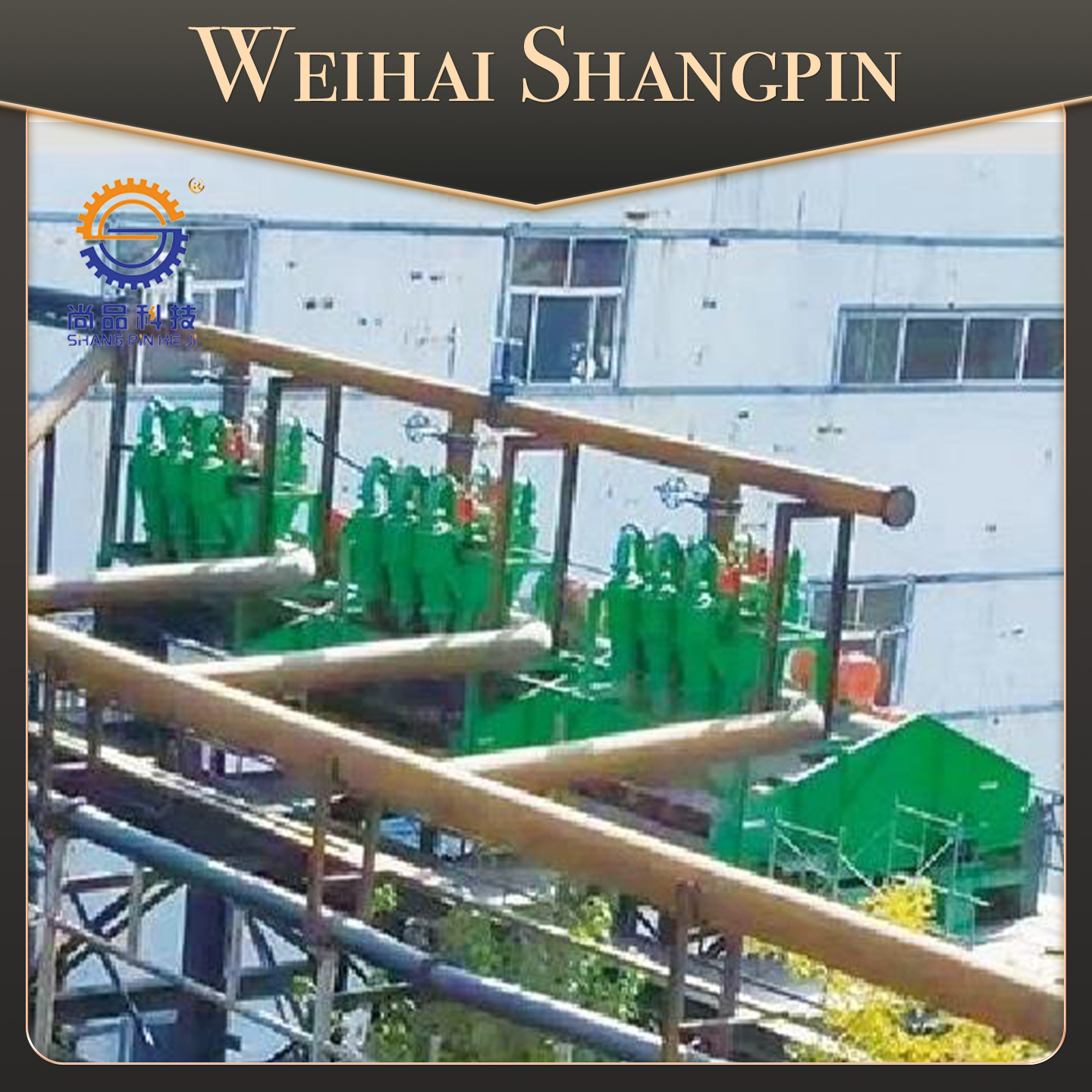

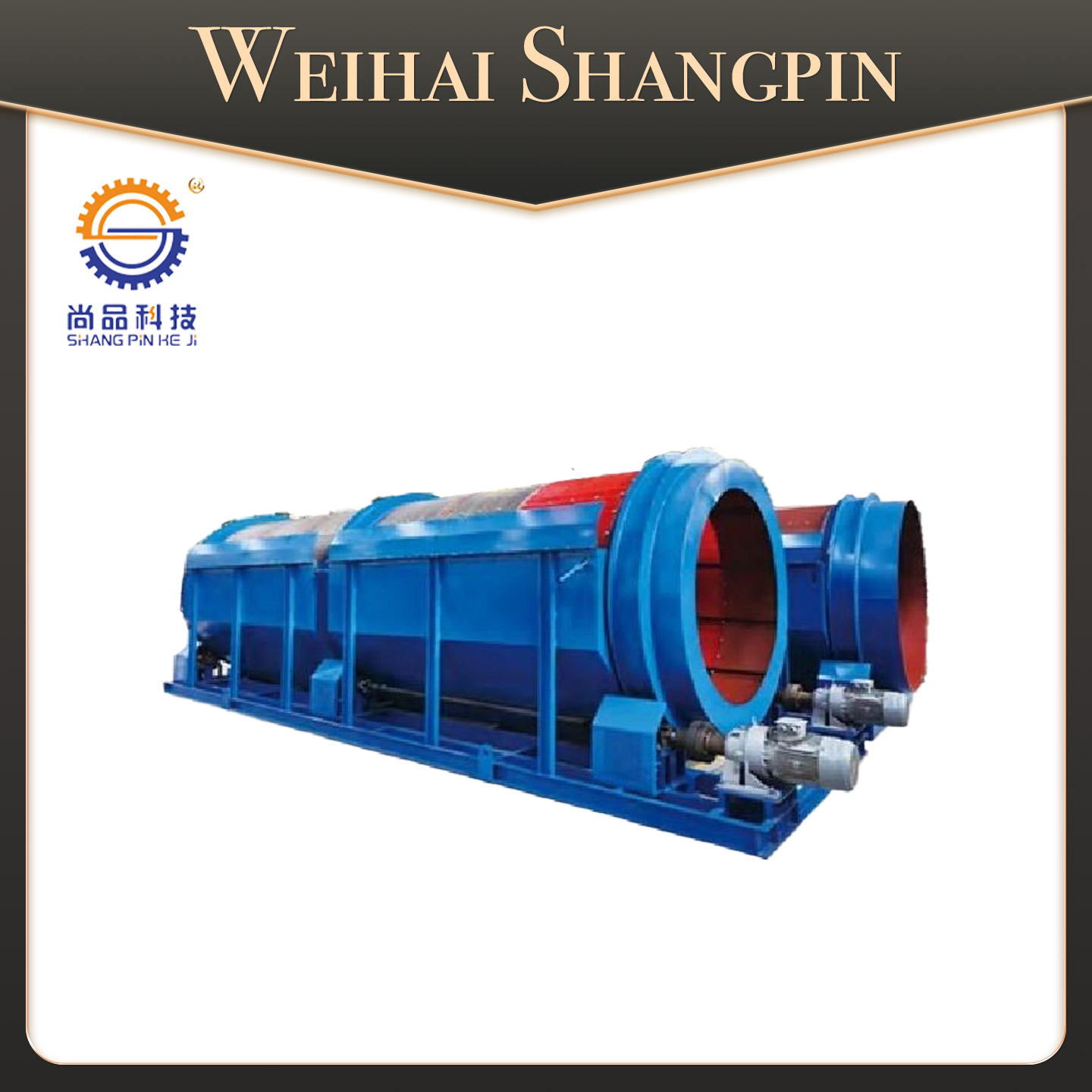

III.Field application examples

微信截图_20220623132149.png)