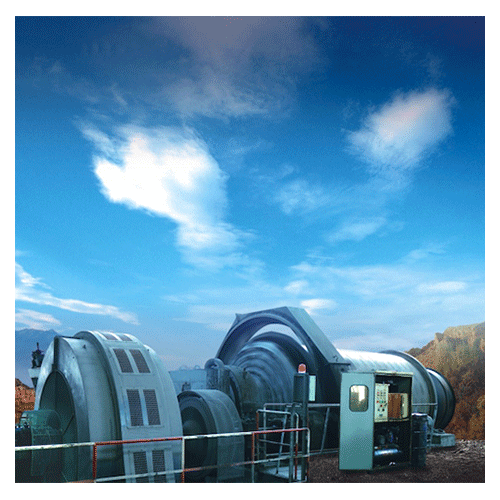

Principle Overview

The main component is a cylinder with a certain reasonable ratio of diameter and length, which is rotated by transmission machinery. The material is fed into the cylinder from the feeding end, and is crushed inside the cylinder due to the impact and self grinding of steel balls and ores. Due to the continuous feeding of materials, the pressure causes the material inside the cylinder to move from the feeding end to the discharging end. The material that reaches the finished particle size is discharged from the discharge end of the cylinder. During wet grinding, the material is carried away by the water flow. The energy-saving grid type ball mill has a discharge grid at the discharge end, and the slurry surface at the discharge port is low, which can reduce ore grinding and prevent steel balls from being discharged. Under the same production conditions, the production capacity is relatively high. Rolling bearings have significant energy savings.

Equipment Features

- The transmission adopts large double row self-aligning roller bearings instead of sliding bearings, which greatly reduces friction, makes starting easy, and saves 20% -30% energy;

- Adopting waveform lining plate increases the contact surface between ball and ore, strengthens the grinding effect, and has the ability to improve the ore, reducing energy consumption;

- Small ball mills below 2.1 meters (excluding 2.1 meters) shall be equipped with integral frames for easy civil construction and equipment installation;

- Large ore discharge outlet with high production capacity;

- Oil mist lubrication device ensures reliable lubrication of large and small gears.

Scope of use

Commonly used for grinding ores with coarser particle sizes.

Technical Parameter

|

Model |

Cylinder Diameter (mm) |

Cylinder Length (mm) |

Motor Model |

Motor Power (kW) |

Length (mm) |

Width (mm) |

Height (mm) |

Processing Capacity (t/h) |

Effective Volume (m ³) |

Maximum Ball Loading Capacity (t) |

Weight (kg) |

|

MQGg 1212 |

1200 |

1200 |

Y200L2-6 |

22 |

3512 |

2076 |

1620 |

0.17~4.1 |

1.14 |

2.4 |

9610 |

|

MQGg 1224 |

1200 |

2400 |

Y280M-8 |

45 |

5745 |

2352 |

1778 |

0.26~6.15 |

2.4 |

4.6 |

12692 |

|

MQGg 1240 |

1200 |

4000 |

JR117-8 |

80 |

7990 |

2210 |

2262 |

0.34~8.3 |

3.8 |

7.8 |

15932 |

|

MQGg 1515 |

1500 |

1500 |

Y280M-8 |

45 |

5740 |

3075 |

2280 |

1.4~4.5 |

2.2 |

5 |

17125 |

|

MQGg 1530 |

1500 |

3000 |

JR117-8 |

80 |

7253 |

3070 |

2280 |

2.8~9 |

5 |

10 |

21425 |

|

MQGg 1536 |

1500 |

3600 |

JR126-8 |

110 |

8595 |

3185 |

2280 |

3~11 |

5.4 |

11.4 |

24213 |

|

MQGg 1545 |

1500 |

4500 |

JR127-8 |

130 |

9680 |

3254 |

2370 |

3.5~12.5 |

7 |

12 |

27346 |

|

MQGg 1830 |

1800 |

3000 |

JR136-8 |

180 |

8250 |

3620 |

2785 |

4.5~27 |

6.65 |

14 |

31850 |

|

MQGg 1836 |

1800 |

3600 |

JR136-8 |

180 |

8866 |

3683 |

2785 |

4.5~29 |

8.2 |

13.8 |

35467 |

|

MQGg 1845 |

1800 |

4520 |

JR137-8 |

210 |

9808 |

3683 |

2785 |

5~35 |

10.2 |

19 |

38909 |

|

MQGg 1856 |

1800 |

5620 |

JR137-8 |

210 |

10909 |

3683 |

2785 |

6~40 |

12.2 |

22 |

41681 |

|

MQGg 1870 |

1800 |

7020 |

JR138-8 |

245 |

12404 |

3783 |

2735 |

7~50 |

15 |

31.5 |

45166 |

|

MQGg 2122 |

2100 |

2200 |

JR128-8 |

155 |

7135 |

4137.7 |

3083 |

5~29 |

6.6 |

20 |

38340 |

|

MQGg 2130 |

2100 |

3000 |

JR136-8 |

180 |

8220 |

4220 |

3083 |

6.5~36 |

9 |

27 |

43100 |

|

MQGg 2136 |

2100 |

3600 |

JR137-8 |

210 |

9154.5 |

4320 |

3433 |

7.5~42 |

10.8 |

23.5 |

45833 |

|

MQGg 2140 |

2100 |

4000 |

JR137-8 |

210 |

9654 |

4320 |

3083 |

7.5~45 |

12.8 |

22.5 |

47262.4 |

|

MQGg 2145 |

2100 |

4500 |

JR137-6 |

280 |

10350 |

4253 |

3125 |

10~50 |

13.5 |

23.6 |

52648 |

|

MQGg 2230 |

2200 |

3000 |

JR137-8 |

210 |

8220 |

3864 |

3183 |

7.5~45 |

9.8 |

20.6 |

44600 |

|

MQGg 2430 |

2400 |

3000 |

JR138-8 |

280 |

9023.5 |

4836.4 |

3490 |

7.2~92 |

11.5 |

22.5 |

59544.5 |

|

MQGg 2436 |

2400 |

3600 |

JR138-8 |

320 |

9604.5 |

4836.4 |

3490 |

8~100 |

13.8 |

25.5 |

63932.5 |

|

MQGg 2442 |

2400 |

4200 |

JR138-8 |

320 |

10204.5 |

4836.4 |

3490 |

8~110 |

16 |

30 |

67370 |

|

MQGg 2721 |

2700 |

2100 |

JR138-8 |

245 |

8300 |

4786.4 |

3495 |

7.2~84 |

10.7 |

23 |

66743 |

|

MQGg 2727 |

2700 |

2700 |

JR137-6 |

280 |

8901 |

4786.4 |

3490 |

7~110 |

13.8 |

29 |

71030 |

|

MQGg 2730 |

2700 |

3000 |

JR1410-8 |

320 |

9610 |

5000 |

3495 |

8~115 |

15.3 |

32 |

83909.2 |

|

MQGg 2732 |

2700 |

3200 |

JR1410-8 |

320 |

10724 |

5000 |

3620 |

8~120 |

15.7 |

32 |

88073 |

|

MQGg 2736 |

2700 |

3600 |

JR158-8 |

380 |

10409 |

5150 |

3620 |

12~145 |

17.7 |

37 |

95300 |

|

MQGg 2740 |

2700 |

4000 |

JR158-8 |

380 |

10609 |

5150 |

3620 |

12.5~152 |

19 |

42 |

98454 |

|

MQGg 2745 |

2700 |

4500 |

JR1510-8 |

450 |

11534 |

5200 |

3670 |

13~160 |

22 |

40 |

100016 |

|

MQGg 2747 |

2700 |

4700 |

JR1510-8 |

475 |

11779 |

5571 |

4175 |

13~170 |

23 |

45 |

101645 |

|

MQGg 2760 |

2700 |

6000 |

JR1512-8 |

630 |

13299 |

5540.6 |

5140 |

15~200 |

30 |

60 |

119546 |

|

MQGg 2836 |

2800 |

3600 |

JR1510-8 |

400 |

10964 |

5350 |

3670 |

13~160 |

19.7 |

41 |

106350 |

|

MQGg 3231 |

3200 |

3100 |

TDMK630-36 |

630 |

12750 |

6750 |

5150 |

14~180 |

22.5 |

45 |

115430 |

|

MQGg 3245 |

3200 |

4500 |

TDMK800-36 |

800 |

13896 |

7200 |

5152.5 |

95~110 |

32.8 |

65 |

147588 |

|

MQGg 3645 |

3600 |

4500 |

TDMK1250-40 |

1250 |

18280 |

7700 |

5496 |

115~170 |

41.5 |

76 |

195727 |