<

>

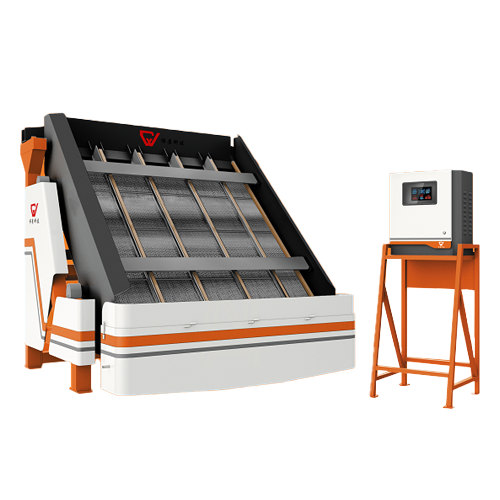

High-frequency Vibrating Fine Screen

Model:

XGPZ2030

Frequency of Vibration:

50Hz

Partition Size:

0.043-3mm

Production Capacity:

COLLECT

Shandong Xinhai Mining Technology&Equipment Inc.

Main Products:Ball mill, flotation machine, classifier, thickener, leaching tank, electrolytic system, dewatering screen, autogenous mill/semi-autogenous mill, wet rod mill, vibrating screen, mixing tank, cyclone, wear-resistant rubber slurry pump, graphite-specific stirring mill, feeder, conveyor, rubber sheet, knife gate valve (non-leakage valve), pinch valve, three-way reversing valve, CNC dosing machine, scrubber, dry ball and rod mill, deoxidizing tower, carbon extraction pump, carbon separator screen, air lifter, baffled settler, electromagnetic iron separator, metal detector, flocculant system, electronic belt scale.

Enter the store

︿

﹀

Details Parameters

Details Introduction

Equipment Features

- High frequency vibration of the screen surface and no movement of the screen box. The exciter is fixed on the screen box, and the excitation force drives the vibration system to excite the screen surface. The vibration system is designed to work in a near resonance state, and can achieve the required vibration parameters with a small driving force. Due to the stationary screen box, the entire machine is supported by secondary vibration reduction, resulting in minimal dynamic load and no need for a special foundation. It can be placed and installed freely;

- The screen surface undergoes high-frequency vibration, with a frequency of 50Hz and an amplitude of 1-2mm. The vibration intensity reaches 8-10 times the gravitational acceleration, which is 2-3 times the vibration intensity of a typical vibrating screen. The screen has strong self-cleaning ability, high screening efficiency, and large processing capacity. Very suitable for screening and dewatering of fine-grained powder materials. The upper limit of feed particle size is 15mm, and the grading particle size is 0.043-3mm;

- The screen surface is composed of three different layers of flexible mesh screens. The bottom layer is made of steel wire rope core polyurethane mesh, which is in direct contact with the vibration excitation device. A composite mesh consisting of two layers of stainless steel wire woven mesh bonded together is tensioned and laid on top of the support mesh. The layers of the composite mesh are in contact with the material, and the mesh size of the upper layer is determined according to the screening process requirements. The mesh has a high opening rate and a long service life. The two ends of the screen are equipped with hooks for easy tensioning and installation. The feeding buffer sieve plate ensures smooth and uniform fabric distribution, reduces the impact of materials on the working mesh (composite mesh), and extends its service life;

- The installation angle of the screening machine can be easily adjusted at any time to adapt to different material properties and screening operations. The inclination angle for wet screening installation in mineral processing plants is generally within the range of 25 ± 2 °, while the inclination angle for dry screening installation is generally within the range of 33 ± 2 °;

- The vibration parameters of the screening machine are controlled by computer adjustment, and the vibration parameters of each vibration system can be adjusted and set through software. In addition to general vibration parameters, intermittent instantaneous strong vibration parameters can also be set to clean the sieve mesh at any time and keep the sieve holes unobstructed;

- The specially designed electromagnetic vibration system mainly uses high-quality rubber components for connection, ensuring reliable long-term operation; Low power consumption, with each electromagnetic exciter having a power of only 0.15kw;

- The screening machine is divided into single channel and double channel, single-layer and multi-layer, adopting modular design, and can be flexibly designed according to specific application scenarios;

- The side panels and middle partitions of the screening box are all formed by bending steel plates as a whole, and the frame is welded and assembled with rectangular pipe profiles, which not only improves the overall rigidity of the screening machine, but also makes the equipment appearance more beautiful;

- The screening machine can be configured with different models of electrical control cabinets according to customers' different needs, to achieve various additional functions such as parameter setting, remote control, process recording, and fault alarm.

Scope of Use

Wet classification is mainly used for the classification of fine-grained materials in mineral processing, consisting of 1-5 layers; The dehydration series is mainly used for dewatering tailings, quartz sand, and coal slurry.

Technical Parameter

|

Model |

Number of screening layers |

Screen surface area (㎡) |

Power (kW) |

Usage |

|

SGPZ2020 |

1 |

4 |

3.8 |

Wet Classification |

|

2SGPZ2020 |

2 |

4 |

3.8 |

Wet Classification |

|

4SGPZ1014 |

4 |

5.6 |

6 |

Wet Classification |

|

5SGPZ1015 |

5 |

7 |

6.48 |

Wet Classification |

|

XGPZ1235 |

1 |

4.2 |

2.6 |

Fine Material Dehydration |

|

XGPZ2030 |

1 |

6 |

6.2 |

Fine Material Dehydration |

Related product recommendations

More Products >

Weihai Shangpin Machinery Equipment Technology Co., Ltd