It is mainly used for tailings recovery in iron ore processing flows, preventing the loss of ore powder and enabling the full utilization of effective resources. It can also be used for magnetic separation of magnetite, limonite, and siderite, effectively reducing costs, increasing profits, and conserving resources.

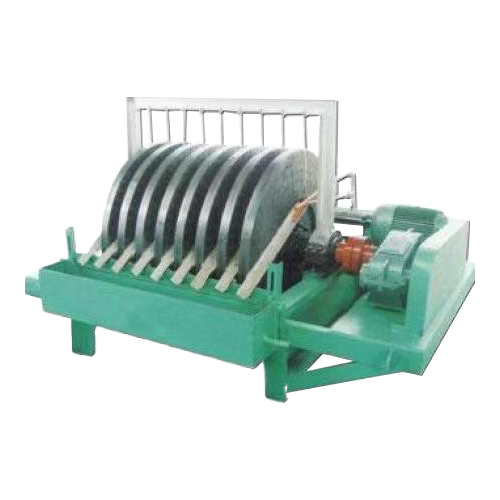

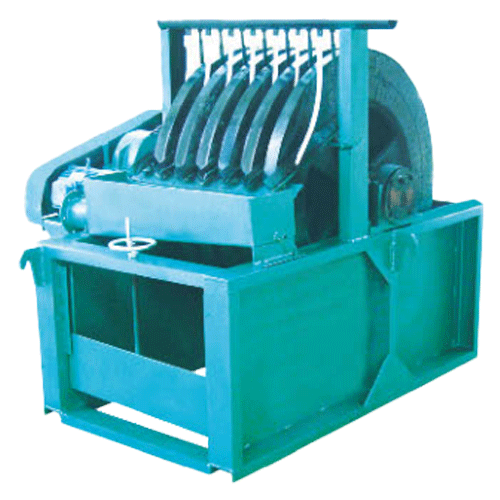

CP series tailing recycling machine consists of five major parts: the main unit, ore discharging device, ore collecting trough, chute, and frame. Its working principle is that the magnetic disks of the main unit are installed in the chute. The ore pulp flows in from one end of the chute and passes through the gaps between the magnetic disks. The magnetic minerals in the ore pulp are adsorbed onto the surface of the magnetic disks, while the remaining non-magnetic mineral ore pulp flows out from the other end of the chute. As the magnetic disks of the main unit rotate, the magnetic minerals adsorbed onto their surfaces are carried out of the ore pulp surface. When they enter the ore discharging area, the ore discharging device inserted between the gaps of the magnetic disks brings the magnetic minerals adsorbed on the magnetic surface into the ore trough for collection and output.

Advantages of the tailings recycling machine:

-

Magnetic Field Arrangement: The magnetic pole spacing between the magnetic disks is small, and there is no zero zone between the disks.

-

Ore Discharging: The ore discharging is non-contact forced discharging. A protective layer of ore powder remains on the surface of the magnetic disks, preventing wear and tear. The overall service life is 8 to 10 times that of conventional models, while also improving the grade of the recovered magnetic minerals.

-

High Processing Capacity: This machine is specially designed for tailings reprocessing. Its structure is characterized by the ability to handle large flows of low-grade tailings, with a processing capacity several times or even dozens of times that of existing drum magnetic separators.

-

High Recovery Rate: All materials passing between the magnetic disks are subjected to magnetic field action, ensuring that magnetic minerals are fully recovered with a high recovery rate.

-

Water Conservation: Due to the unique magnetic field arrangement, the magnetic minerals contain a large amount of water and the discharged minerals are in a fluid state, basically requiring no or only a small amount of supplementary water.

-

Energy Saving: The processing capacity of one tailings recovery machine is several times or even more than ten times that of other ordinary equipment, but its installed capacity is only a few kilowatts, resulting in significant energy savings.

-

Easy Installation: The tailings recovery machine has a high processing capacity, occupies a small area, and requires a small difference in feed and discharge levels. It can be installed basically anywhere there is a tailings chute.

-

High Economic Benefits: The equipment investment is small, and the output benefits are high.

CP series tailing recycling machine

| specifications | Number of disks | Disk diameter(mm) |

Magnetic field intensity on disk surface(mT) | Content of feeder(%) |

Processing volume(t/h) | Motor power(KW) |

Disk speed(r/min) |

Sorting particle size(mm) | Weight(T) | Exterior size(mm) |

| CP-600-4 | 4 | 600 | 100-500 | 8-20 | 30-50 | 1.5 | 1.5-14.4 | 0-1 | 0.8 | 1230×1320×1050 |

| CP-800-4 | 4 | 800 | 40-60 | 2.2 | 1 | 1430×1320×1100 | ||||

| CP-800-6 | 6 | 800 | 60-80 | 2.2 | 1.2 | 1430×1530×1100 | ||||

| CP-100-4 | 4 | 1000 | 80-100 | 2.2 | 1.2 | 1630×1370×1280 | ||||

| CP-100-6 | 6 | 1000 | 130-150 | 3 | 1.6 | 1630×1580×1280 | ||||

| CP-100-8 | 8 | 1000 | 170-190 | 4 | 2 | 1630×1800×1280 | ||||

| CP-100-10 | 10 | 1000 | 220-240 | 5.5 | 2.4 | 1630×2010×1280 | ||||

| CP-100-12 | 12 | 1000 | 270-290 | 5.5 | 2.8 | 1630×2230×1280 | ||||

| CP-120-12 | 12 | 1200 | 300-320 | 5.5 | 3.9 | 1830×2425×1510 |

TD系列永磁笼式尾矿回收机.png)