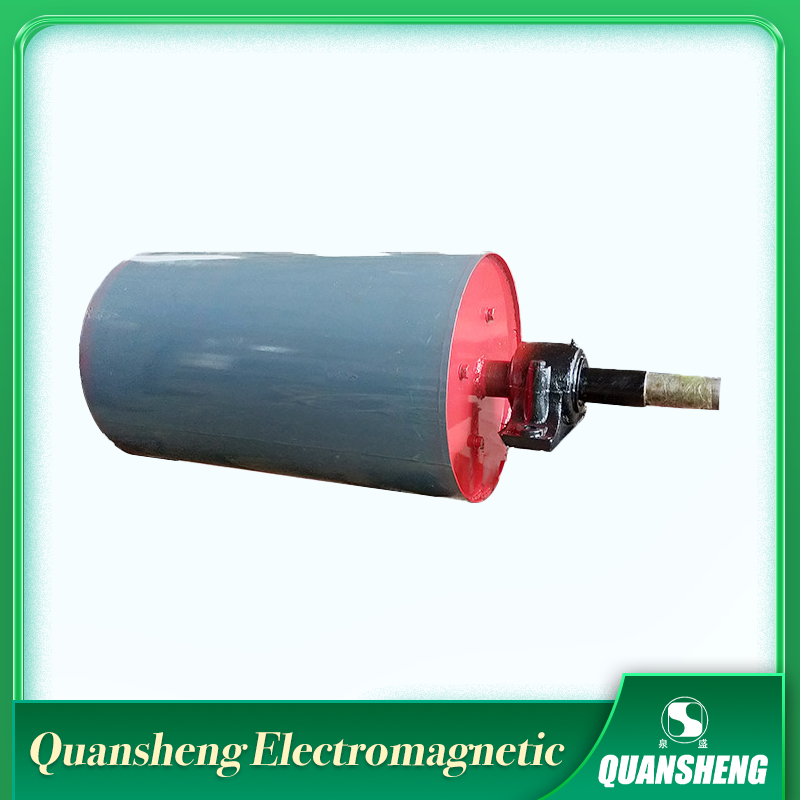

QSGX Series Dry (wet)dual purpose permanent magnet drum magnetic separator

Dry and Wet Dual-Purpose Cylindrical Magnetic Separator

Application:

Preliminary selection of sand minerals, concentration and magnetic separation of river sand, sea sand, weathered sand, and other minerals, as well as iron concentrate recovery from mineral tailings. Examples include sorting low-grade magnetite, river sand, and steel slag. The machine initially eliminates excess tailings, thereby enriching the grade of poor-grade ore.

Working Principle:

Minerals are uniformly fed to the upper part of the magnetic separation drum via a vibrating feeder. The rotating drum body throws non-magnetic materials away, while magnetic materials are attracted by the strong magnetic field towards the drum body and transported to the magnetic material unloading area, thus separating magnetic and non-magnetic materials.

Technical Advantages:

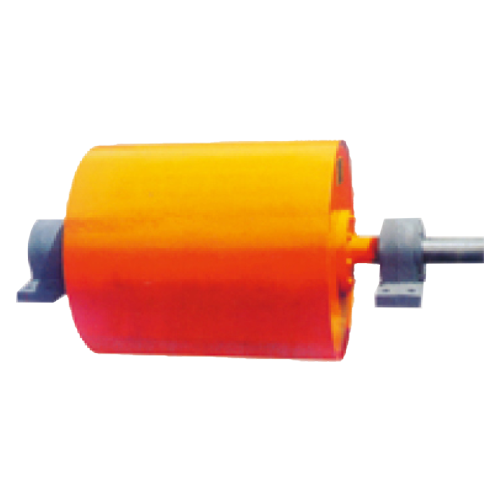

- Utilizes neodymium-iron-boron magnetic blocks

- Precision-machined magnetic tracks

- Uniform magnetic system

- High magnetic strength

- High central magnetic field intensity

- Rational magnetic block arrangement

- Enhances multi-level rolling of minerals on the drum surface

- Facilitates better impurity removal and grade improvement

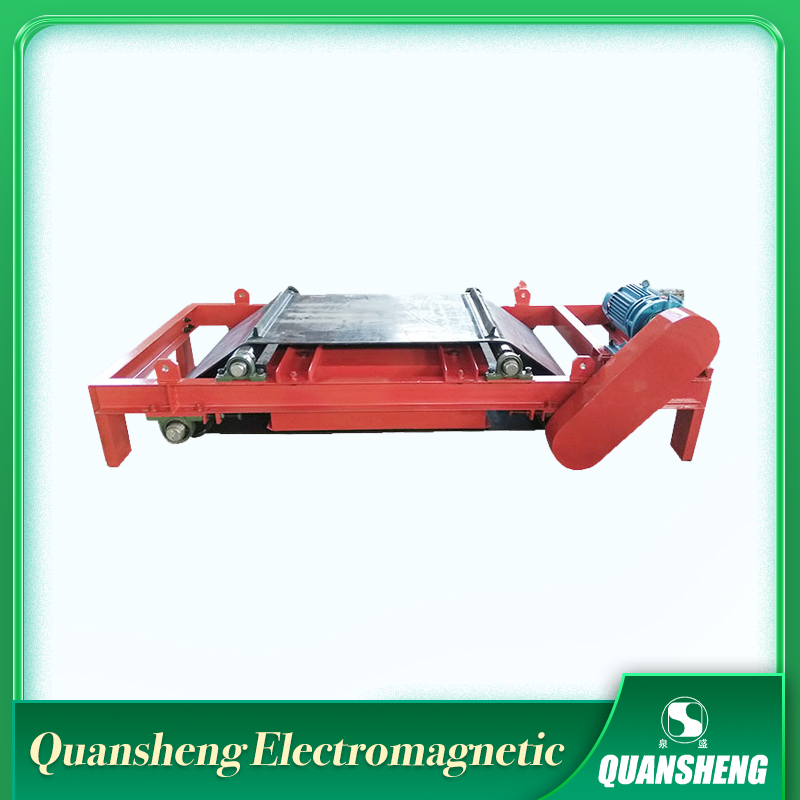

The designed feeding machine provides uniform material feeding to achieve optimal magnetic separation effects. The power component system supplies sufficient and stable power output for the entire separation system.

QSGX Series Dry (wet)dual purpose permanent magnet drum magnetic separator

| Model | Cylinder size |

Magnetic field intensity(mT) |

rocessing volume(T/h ) |

Motor power(kw) | Drum speed(r/min) |

Reducer model |

Total power(kw) |

| QSGX-7524 | 750×2400 | 100-600 | 40-80 | 11 | 30-60 | ZQ-350 | 15.1 |

| QSGX-9024 | 900×2400 | 80-120 | 15 | 30-60 | ZQ-350 | 19.1 | |

| QSGX-9026 | 900×2600 | 120-160 | 15 | 30-60 | ZQ-350 | 19.1 | |

| QSGX-9030 | 900×3000 | 160-190 | 15 | 30-60 | ZQ-400 | 19.1 | |

| QSGX-1024 | 1050×2400 | 120-160 | 15 | 30-50 | ZQ-350 | 19.1 | |

| QSGX-1026 | 1050×2600 | 160-210 | 18.5 | 30-50 | ZQ-400 | 22.6 | |

| QSGX-1030 | 1050×3000 | 180-250 | 22 | 30-50 | ZQ-400 | 26.1 |