Purpose:

High field strength roller magnetic separator is a magnetic separation/iron removal equipment used for some weak magnetic minerals or non-magnetic minerals.

It is mainly applied for tailings discarding or purification and upgrading of fine-grained weak magnetic minerals; it is also used for refining treatment (iron and titanium impurity removal) of raw materials and products of non-metallic minerals such as andalusite, sillimanite, kyanite, garnet, feldspar, quartz, rutile, zircon, corundum, etc.; it can also be used to remove weak magnetic harmful impurities in various abrasive products, catalysts, and other materials. It is widely used in removing weak magnetic impurities from fine-grained or coarse powdered materials. In addition, various specifications and sizes of strong magnetic rollers can be designed and manufactured according to actual production volume.

Working Principle:

Non-magnetic materials containing magnetic substances are evenly distributed onto the belt of the strong magnetic roller magnetic separator by an electromagnetic vibrating feeder; when the materials pass through the strong magnetic roller, the magnetic substances are adsorbed onto the roller due to magnetic force and carried into the magnetic material collection hopper by the belt; non-magnetic materials and unseparated magnetic materials fall off the magnetic field and onto the next belt for further separation due to gravity as the belt rotates; in this way, qualified products can be separated after several magnetic separation processes.

Main Structural Features:

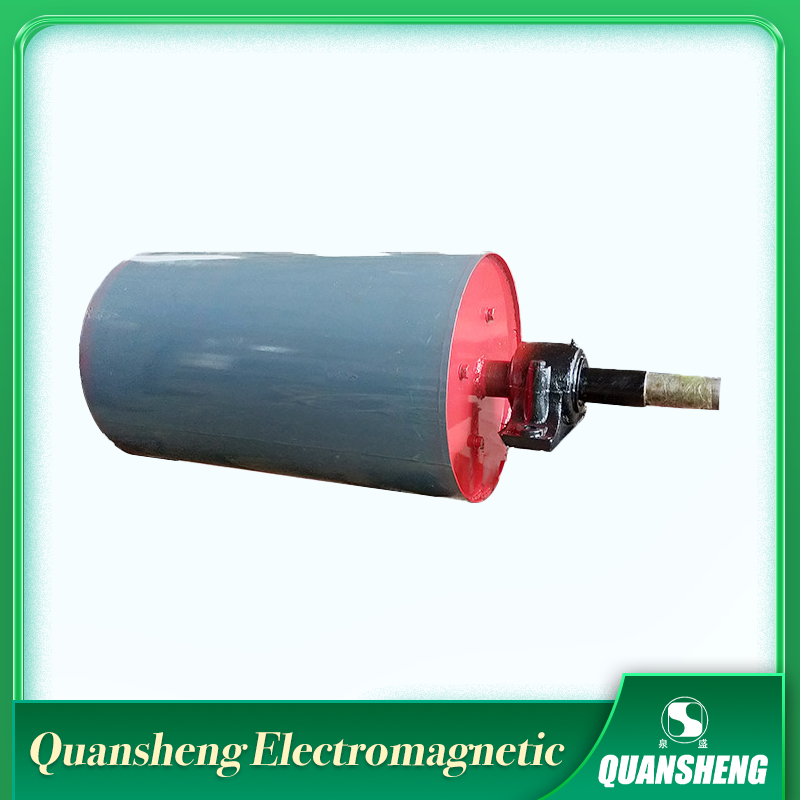

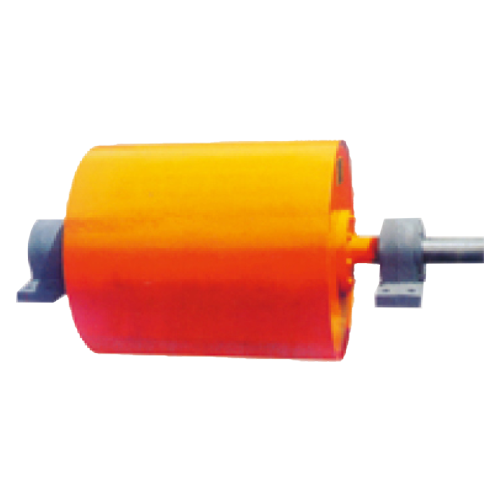

The machine consists of a frame, casing, material bin and feeding adjustment mechanism, permanent magnetic roller, driven roller, conveyor belt, stepless variable speed transmission device, vibrating feeder, etc. It features a compact structure, small volume, light weight, low power consumption, and energy saving. The vibrating feeder is used for feeding, with uniform feeding and adjustable feeding volume. The stepless variable speed transmission allows adjustment of the magnetic roller speed according to the particle size of the material; a larger particle size corresponds to a lower speed, while a smaller particle size corresponds to a higher speed.

The opening size of the material distribution plate can be adjusted according to the material grade. A larger opening size is used. The rear outlet is the outlet for ferromagnetic substances.

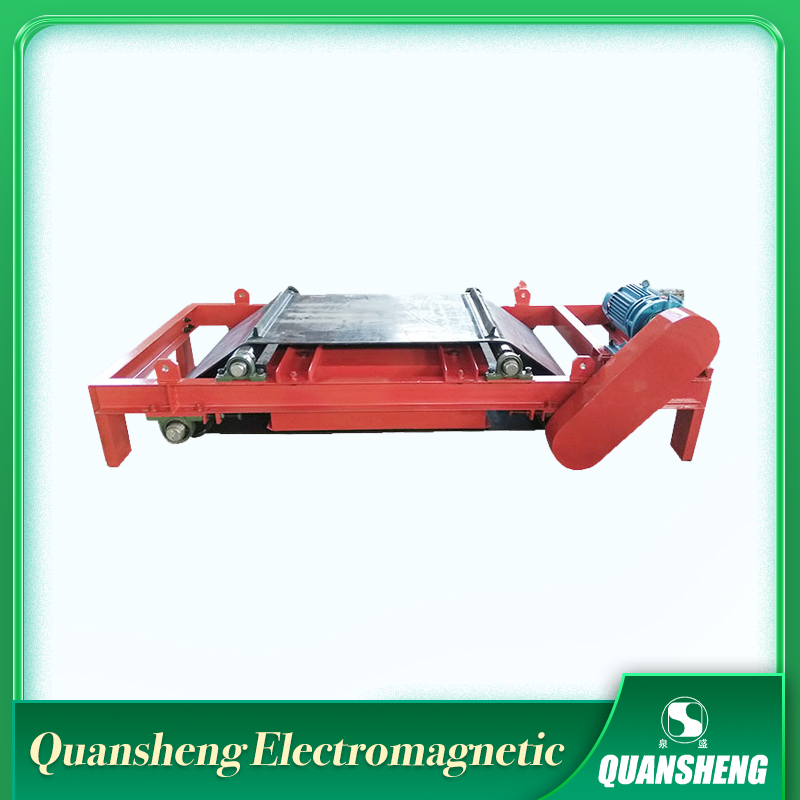

QSDG series multi roll permanent magnetic separator

High field strength roller magnetic separator

| specifications | Magnetic roller size | Speed(r/min) | Magnetic induction(Gs) | Main motor power(Kw) |

Vibration motor power(Kw) |

Feeder particle size(mm) |

Processing volume(t/h) |

|

| Roller diameter(mm) | Effective length(mm) | |||||||

| QSDG-100×600 | 100 | 600 | 150-350 | ≥15000 | 1.1 | 0.75 | 0-15 | 0.3-0.6 |

| QSDG-100×800 | 100 | 800 | 150-350 | 0.4-0.8 | ||||

| QSDG-100×1000 | 100 | 1000 | 150-350 | 0.5-1 | ||||

| QSDG-150×600 | 150 | 600 | 150-350 | 0.4-0.9 | ||||

| QSDG-150×800 | 150 | 800 | 150-350 | 0.6-1.2 | ||||

| QSDG-150×1000 | 150 | 1000 | 150-350 | 0.7-1.5 | ||||

| QSDG-240×600 | 240 | 600 | 150-300 | 0.7-1.4 | ||||

| QSDG-240×800 | 240 | 800 | 150-300 | 0.9-1.9 | ||||

| QSDG-240×1000 | 240 | 1000 | 150-300 | 1.2-2.4 | ||||

| QSDG-300×600 | 300 | 600 | 150-250 | 0.9-1.8 | ||||

| QSDG-300×800 | 300 | 800 | 150-250 | 1.2-2.4 | ||||

| QSDG-300×1000 | 300 | 1000 | 150-250 | 1.5-3 | ||||

| Note:Can be made into single roll,double roll,multi rol according to customer requirements | ||||||||