Application:

Primarily used for automatically removing ferromagnetic substances from non-magnetic materials on conveyor belts. Widely applied in industries such as grain, power, mining, metallurgy, building materials, coal selection, chemical processing, coal transportation ports, glass, and others, enabling continuous iron removal.

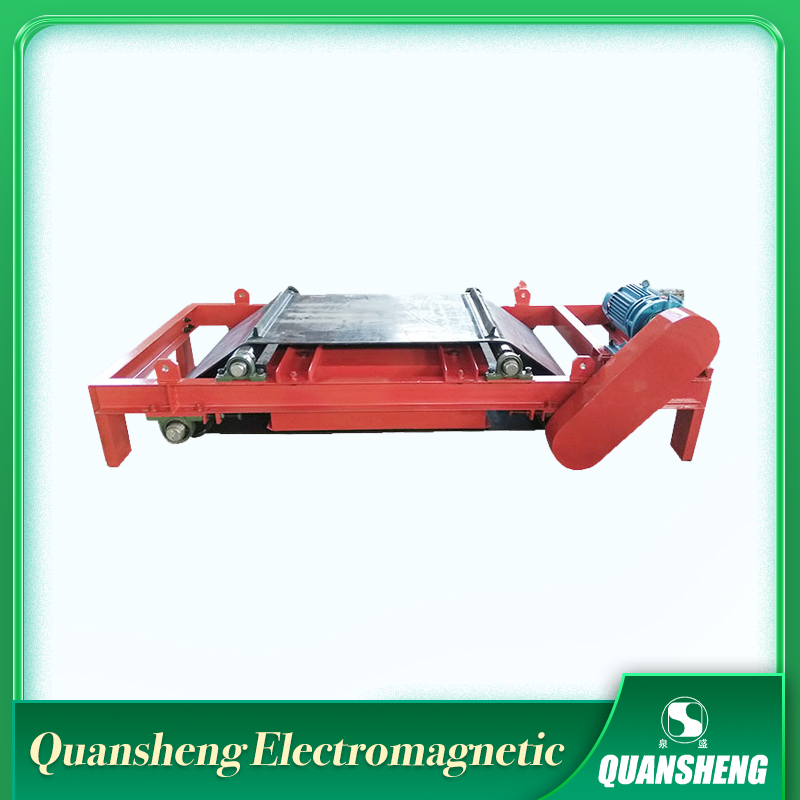

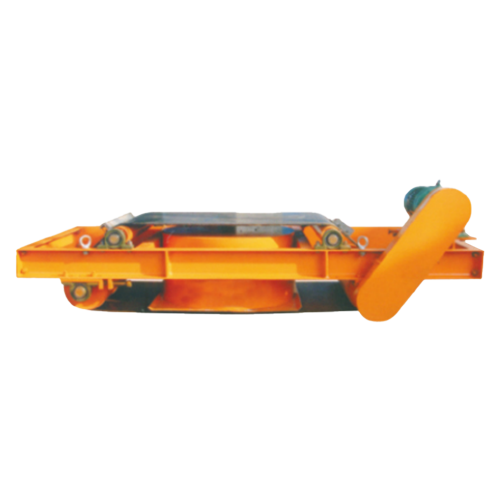

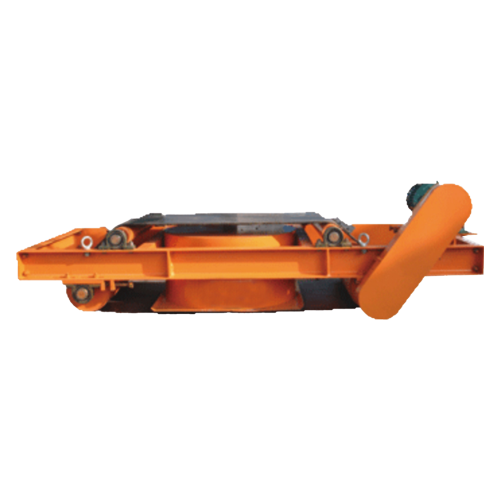

Permanent-magnet self discharge iron remover: Working Principle and Characteristics:

The permanent-magnet self discharge iron remover is an enhanced version of the suspended permanent magnet iron remover, equipped with an automatic iron discharge mechanism. During operation, the iron remover suspended above the transport equipment uses powerful magnetic force to extract iron impurities mixed within the materials. The iron impurities attracted to the bottom of the iron remover are carried by the discharge belt and thrown into the iron collection box, achieving automatic removal. This type of iron remover can automatically remove absorbed iron impurities, making it suitable for environments with high iron content that require frequent iron removal.

Product Advantages:

1. Constant and reasonably distributed magnetic field with significant magnetic depth;

2. Simplified main body compared to electromagnetic iron removers, requiring no excitation power source or cooling system;

3. Energy-saving and low failure rate;

4. Simple operation and smooth running;

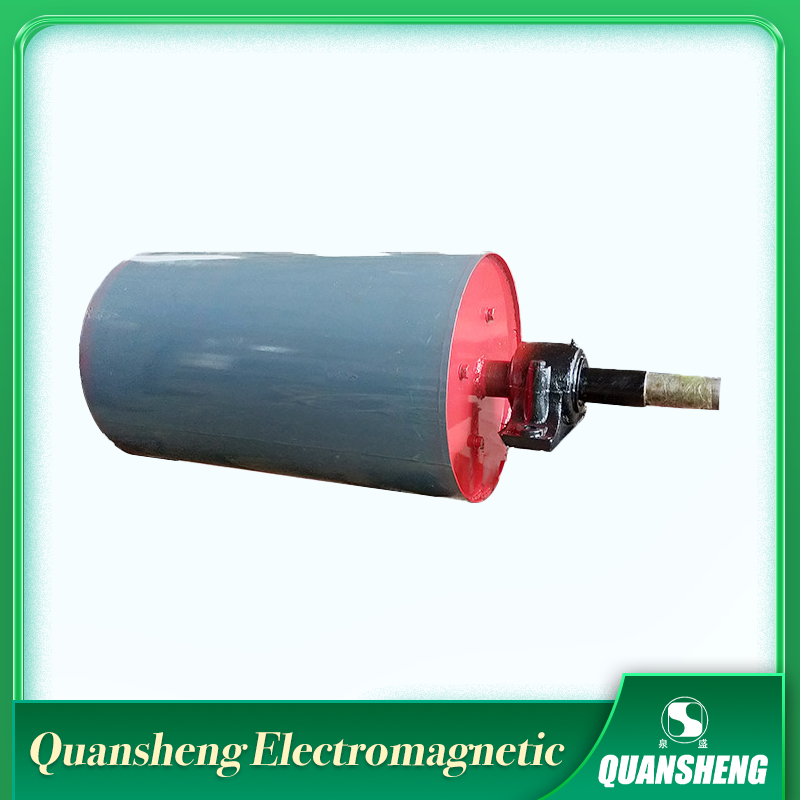

5. Waist drum roller structure with automatic tracking correction function;

6. Sealed bearing housing with excellent sealing performance, adaptable to various harsh environments.

Iron removal equipment

RCYD Series permanent-magnet self discharge iron remover

| Model | Matching belt width(mm) |

Rated hoisting height(mm) |

Magnetic field intensity(≥mT) |

Material thickness(≤ mm) |

Driving power(KW) | Fit belt speed(≤m/s) | Way to work | Weight(kg) |

| RCYD-5 | 500 | 150 | 60 | 80 | 1.5 | 2.5 | continuity | 750 |

| RCYD-6 | 600 | 175 | 60 | 120 | 1.5 | 920 | ||

| RCYD-6.5 | 650 | 200 | 70 | 150 | 1.5 | 1200 | ||

| RCYD-8 | 800 | 250 | 70 | 200 | 2.2 | 1400 | ||

| RCYD-10 | 1000 | 300 | 70 | 250 | 3 | 2120 | ||

| RCYD-12 | 1200 | 350 | 70 | 300 | 4 | 3350 | ||

| RCYD-14 | 1400 | 400 | 70 | 350 | 4 | 4450 | ||

| RCYD-16 | 1600 | 450 | 70 | 400 | 5.5 | 6200 | ||

| RCYD-18 | 1800 | 500 | 72 | 450 | 5.5 | 8100 | ||

| RCYD-20 | 2000 | 550 | 72 | 500 | 7.5 | 9700 |

自卸式永磁除铁器.png)