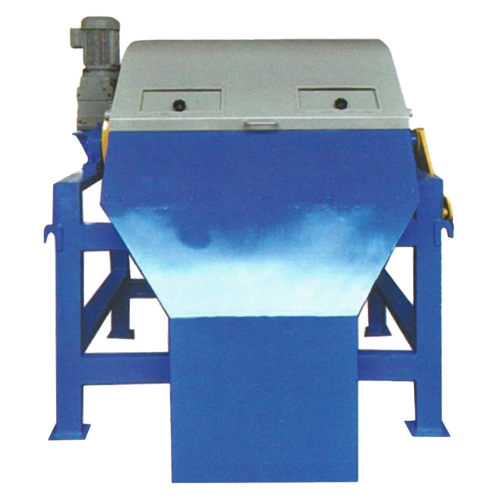

This machine is widely used in mineral processing, coal washing, chemical industry, and other sectors for wet separation of strong magnetic minerals with particle sizes ranging from 6 to 0 millimeters. It divides the minerals into two products: magnetic substances and non-magnetic substances. The specific magnetization coefficient (χ) of the strong magnetic substances it separates should not be less than 3000×10-6 cubic centimeters per gram. Minerals belonging to this category include magnetite, pyrrhotite, etc. For hematite, limonite, siderite, and other minerals, pre-magnetic roasting is required before separation can be performed.

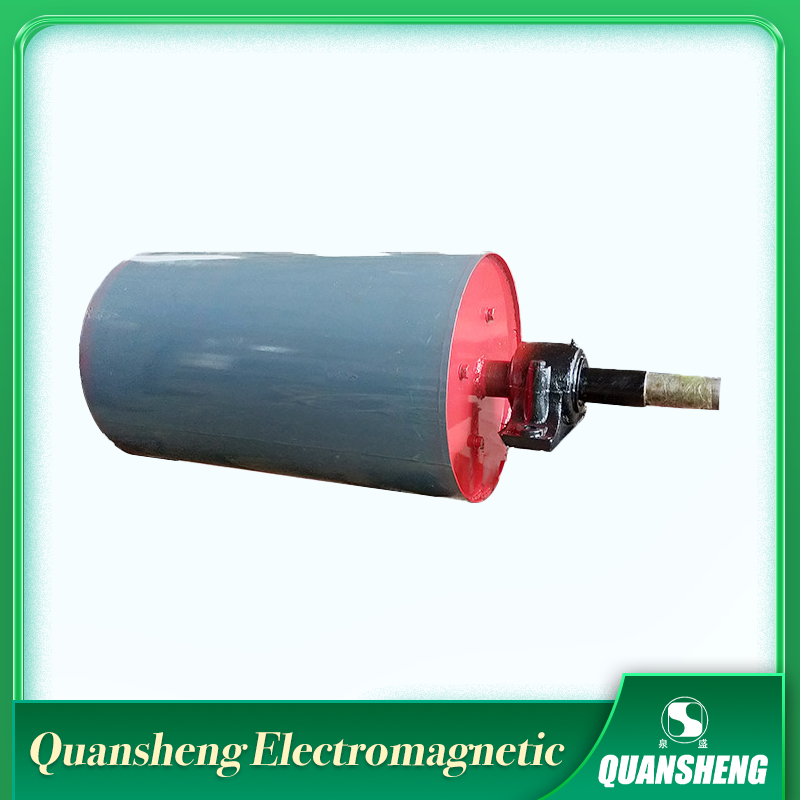

The same cylinder can be equipped with three types of tanks: semi-countercurrent tank, countercurrent tank, and concurrent tank, to adapt to different separation processes.

The semi-countercurrent tank is suitable for wet roughing and cleaning of strong magnetic minerals with ore particle sizes of 0.5 to 0 millimeters, especially for the cleaning of minerals with particle sizes of 0.15 to 0 millimeters.

The countercurrent tank is suitable for wet roughing and scavenging of strong magnetic minerals with ore particle sizes of 0.6 to 0 millimeters, particularly for the recovery of heavy media in coal washing plants.

The concurrent tank is suitable for wet roughing and cleaning of strong magnetic minerals with ore particle sizes of 6 to 0 millimeters. It can also be used for the recovery of heavy media in coal washing plants, among other applications. Both semi-countercurrent tanks and concurrent tanks can be used in series to improve the grade of concentrate.

CTB Series permanent magnet wet magnetic separator

| Model | Cylinder size (mm) |

magnetic field intensity (T) |

Processing volume |

Motor power (KW) |

Drum speed (r/min) | Weight (T) |

Reducer model |

Feeder particle size |

|

| T/h | m3/h | ||||||||

| CTB(N.S) -718 | 700×1800 | 80-600 | 20-45 | 72 | 3 | 35 | 2.05 | ZQ-250 | 1-0 |

| CTB(N.S) -918 | 900×1800 | 25-55 | 90 | 5.5 | 28 | 2.9 | ZQ-350 | ||

| CTB(N.S) -1018 | 1050×1800 | 40-75 | 120 | 5.5 | 22 | 4.02 | ZQ-350 | ||

| CTB(N.S) -1024 | 1050×2400 | 52-100 | 160 | 5.5 | 22 | 4.71 | ZQ-350 | ||

| CTB(N.S) -1030 | 1050×3000 | 65-125 | 200 | 7.5 | 22 | 6.2 | ZQ-400 | ||

| CTB(N.S) -1224 | 1200×2400 | 62-120 | 192 | 7.5 | 19 | 6.35 | ZQ-400 | ||

| CTB(N.S) -1230 | 1200×3000 | 80-150 | 240 | 11 | 19 | 7.2 | ZQ-400 | ||

| CTB(N.S) -1530 | 1500×3000 | 90-170 | 270 | 11 | 14 | 8.1 | ZQ-500 | ||

| CTB(N.S) -1540 | 1500×4000 | 115-220 | 350 | 15 | 14 | 9.3 | ZQ-500 | ||

| CTB(N.S) -1545 | 1500×4500 | 130-250 | 400 | 22 | 14 | 9.9 | ZQ-500 | ||

| CTB(N.S) -1550 | 1500×5000 | 170-280 | 440 | 22 | 14 | 10.5 | ZQ-500 | ||

湿式强磁场磁选机1.png)