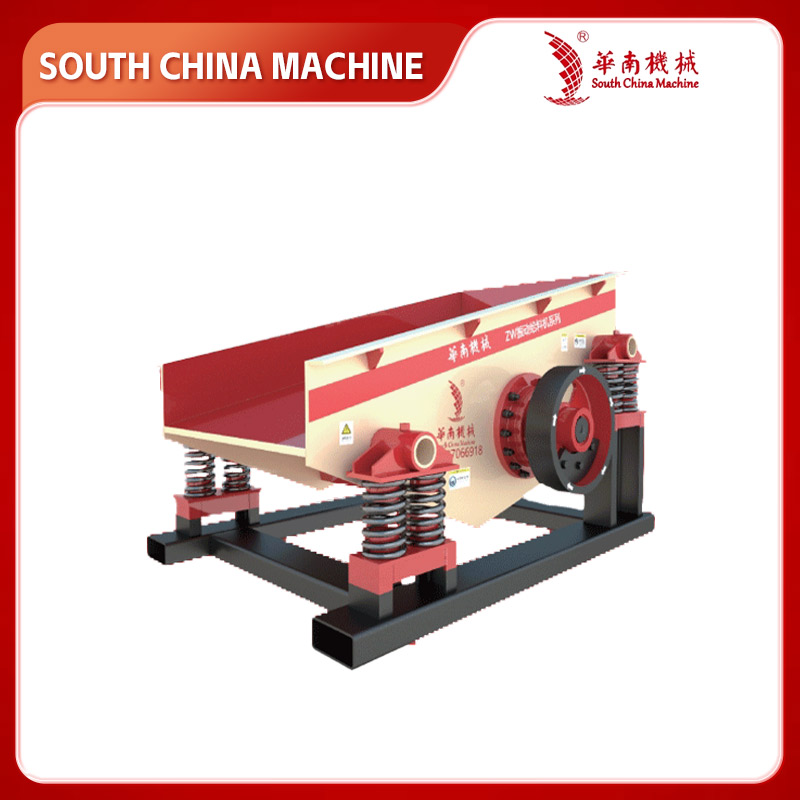

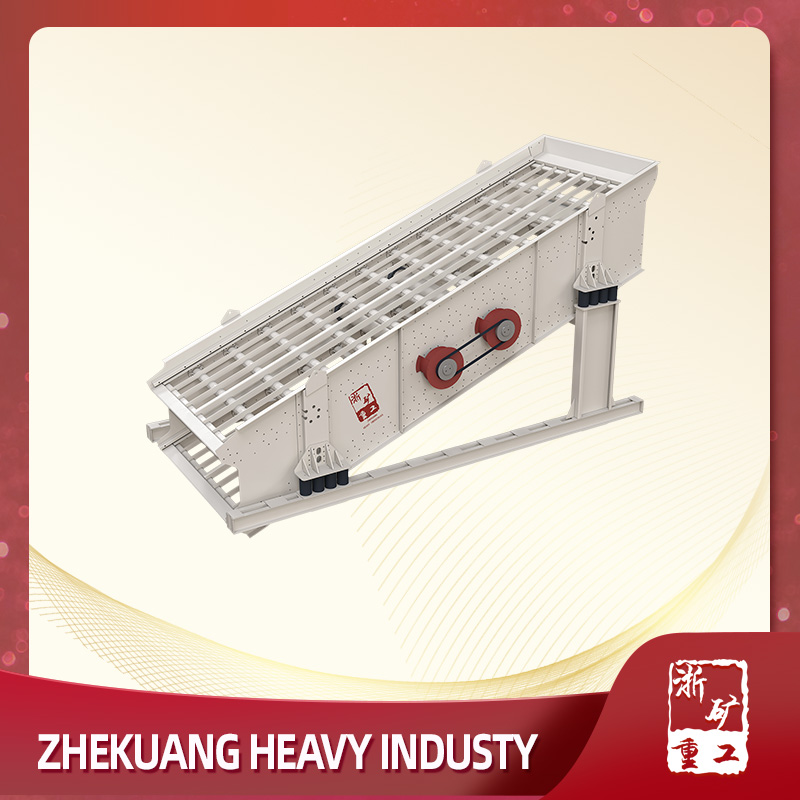

Product Introduction

The ZWS dual axis vibration feeder mainly consists of a vibration frame, springs, vibrators, motor vibration frames, and motors.

The exciter is composed of two eccentric shafts at specific positions that mesh with gears. During assembly, the two gears must mesh with each other according to the markings. The two eccentric shafts are driven by an electric motor to rotate, generating a huge synthetic linear excitation force, which forces the body to vibrate forcefully on the supporting spring. The material then uses this vibration as the driving force to slide and throw on the material groove, thereby moving the material forward and achieving the feeding purpose. When the material passes through the sun strip on the tank, smaller materials can fall through the gap between the sun strips and do not go through the next crushing process, achieving the effect of screening.

Technical Paramter

|

Model |

Maximum feeding size(mm) |

Processing capacity(t/h) |

Motor power(kw) |

Tilt angel |

Machine weight(kg) |

|

ZWS1300×6000 |

700 |

100-700 |

30 |

8°-12° |

9000 |

|

ZWS1400×6000 |

800 |

100-700 |

30 |

8°-12° |

10000 |

|

ZWS1500×6000 |

900 |

200-1000 |

30 |

8°-12° |

11000 |

|

ZWS1800×6500 |

1000 |

300-1200 |

45 |

8°-12° |

16000 |

ZSW震动式给料机√.png)

圆盘给料机2.png)