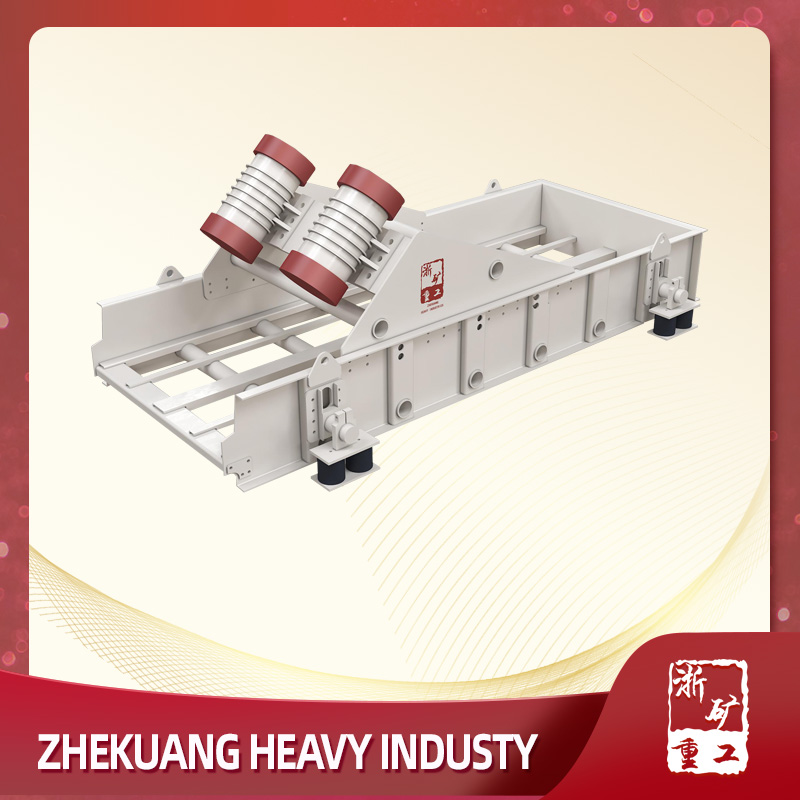

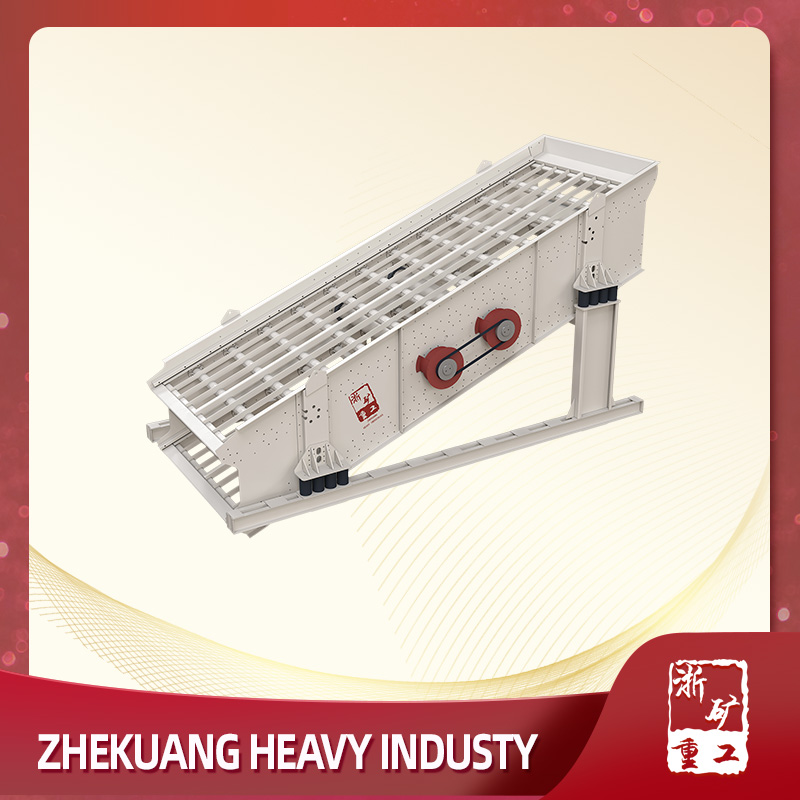

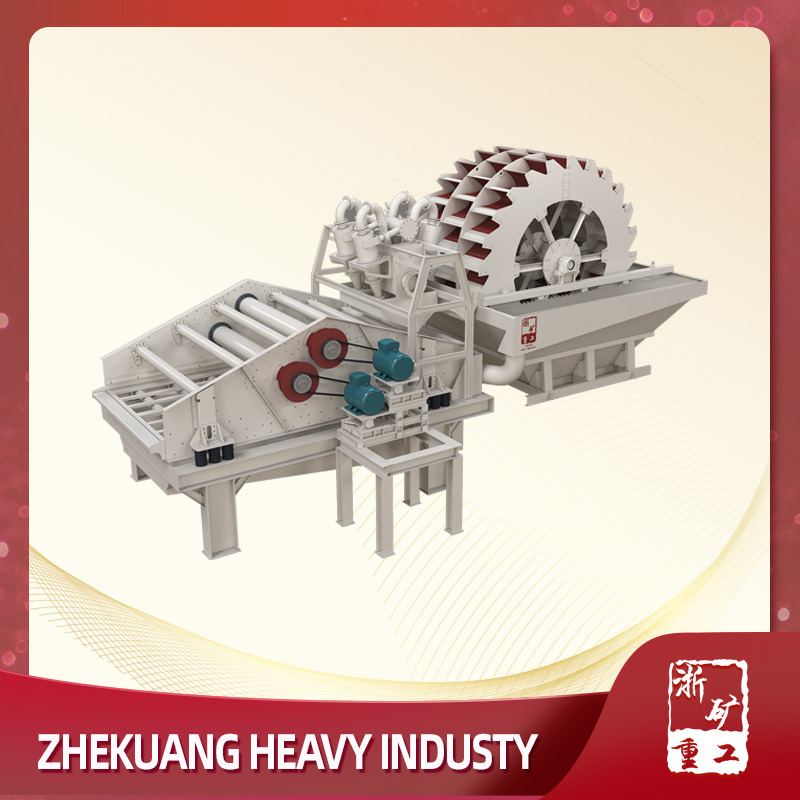

Product Introduction

The ZJS linear vibrating screen is driven by dual vibration motors. When two vibration motors rotate synchronously or in reverse, the excitation force generated by their eccentric blocks cancels out each other in the direction parallel to the motor axis, and stacks into a combined force in the direction perpendicular to the motor axis. Therefore, the motion trajectory of the screen machine is a straight line. The two motor shafts have an inclination angle relative to the screen surface. Under the combined force of excitation force and boring self gravity, the material is thrown up on the screen surface and jumps forward in a linear motion, performing dry and wet screening, dehydration, media removal, and sludge removal on medium and fine strength materials. It is widely used in industries such as mining, coal, smelting, building materials, refractory materials, light industry, and chemical industry.

Performance Characteristics

1. Simple and reasonable structure, high screening efficiency, low noise, low energy consumption, and convenient maintenance;

2. The unique screen structure design makes it convenient and quick to replace the screen.

Technical Parameter

|

Model |

Screen mesh area(㎡) |

Feeding grain size(mm) |

Processing capacity(t/h) |

Vibration frequency |

Double amplitude(mm) |

Motor power(kw) |

Vibration weight(kg) |

|

ZJS0822 |

1.76 |

≤100 |

15-40 |

960 |

4~8 |

2×1.5 |

1500 |

|

ZJS1022 |

2.20 |

≤100 |

20-50 |

960 |

4~8 |

2×1.5 |

1950 |

|

ZJS1232 |

3.84 |

≤100 |

30-80 |

960 |

4~8 |

1×3.2 |

3150 |

|

ZJS1437 |

5.18 |

≤150 |

35-100 |

960 |

4~8 |

2×3.7 |

4200 |

|

ZJS1845 |

8.10 |

≤200 |

50-200 |

960 |

4~8 |

2×7.5 |

6300 |

|

ZJS2048 |

9.60 |

≤200 |

70-230 |

960 |

4~8 |

2×7.5 |

8350 |

|

ZJS2460 |

14.4 |

≤200 |

100-350 |

960 |

4~8 |

2×9 |

9700 |

4.png)