Introduction to Features

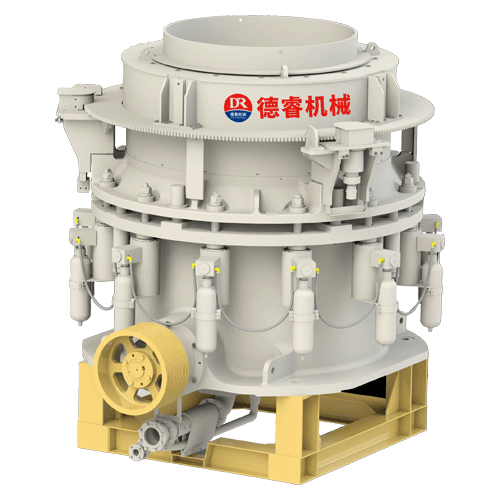

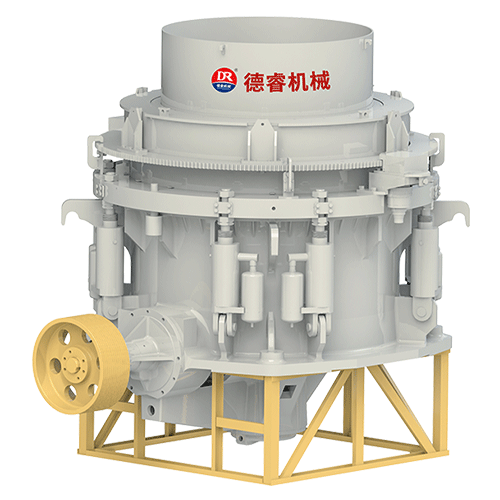

The MRC series multi cylinder hydraulic rolling bearing cone crusher, through advanced design and optimized cavity shape, produces better stone grading and increases throughput.

This series of products is suitable for various fields such as metal and non-metal mines, building materials, chemical raw materials, etc. This series of machines has the following advantages:

1. The advanced design of the crushing chamber enhances the content of cubic products; Longer crushing chamber and greater retention force result in higher throughput; Multiple speeds and cavity types are used to produce more products and reduce energy consumption.

2. Adopting a full rolling bearing design, it can convert more horsepower into crushing force. At the same time, it reduces friction and heat, resulting in higher production per unit time and prolonging the service life of bearings.

3. Adopting large-diameter thrust bearings improves the bearing capacity and is more suitable for metal mines with hard ores.

4. The heavy-duty cast steel frame can withstand harsh working conditions and extend its service life.

5. Adopting a hydraulic control system, the discharge port adjustment is convenient and fast, and provides more reliable overload protection.

6. Advanced automation control system with simple operation makes the machine run more stably.

7. Use a backstop to prevent the rotation of the moving cone during no-load operation and reduce additional wear.

8. Simply replace the lining plate to achieve the transformation between coarse and fine crushing to meet different crushing requirements.

Technical Parameter

|

Model |

Maximum feed size(mm) |

Power(kW) |

Discharge port size(mm) |

Weight |

|||||||||

|

Open circuit output(t/h) |

|||||||||||||

|

10 |

13 |

16 |

19 |

22 |

25 |

32 |

38 |

44 |

51 |

||||

|

MRC40 |

275 |

200 |

120-150 |

150-190 |

190-250 |

230-300 |

210-275 |

230-300 |

260-335 |

305-390 |

355-445 |

440-490 |

16600 |

|

MRC45 |

325 |

280 |

190-250 |

220-285 |

240-310 |

280-365 |

305-395 |

335-435 |

405-525 |

445-580 |

490-640 |

|

22000 |

|

MRC54 |

300 |

315 |

240-360 |

265-400 |

280-420 |

305-460 |

325-485 |

390-510 |

470-610 |

515-670 |

565-735 |

620-805 |

30000 |

|

MRC66 |

400 |

400 |

280-430 |

320-480 |

335-505 |

365-550 |

385-580 |

465-625 |

585-760 |

645-840 |

710-925 |

780-1015 |

43000 |

Note: The production capacity of the crusher given in the above table can be used as a preliminary selection reference. The data in the table is based on a material loose density of 1600kq/m ³。 The corresponding condition is open circuit crushing, whose feeding size meets the maximum allowable feeding particle size of the crusher, and does not contain materials smaller than the size of the crusher's tight edge discharge port, such as production capacity under pre screening open circuit operation conditions; The fine particle content in the feed is relatively high, for example, under closed circuit operation conditions, the production capacity is 15-30% higher than open circuit production capacity. Due to differences in material type, feed gradation, moisture content, installed lining plate type, and material type, the production capacity of the crusher may be affected. The actual production results may differ from those in the table. In order to choose a crusher suitable for your specific conditions, please consult Zhejiang Mining Heavy Industry.

多缸液压圆锥破碎机.png)