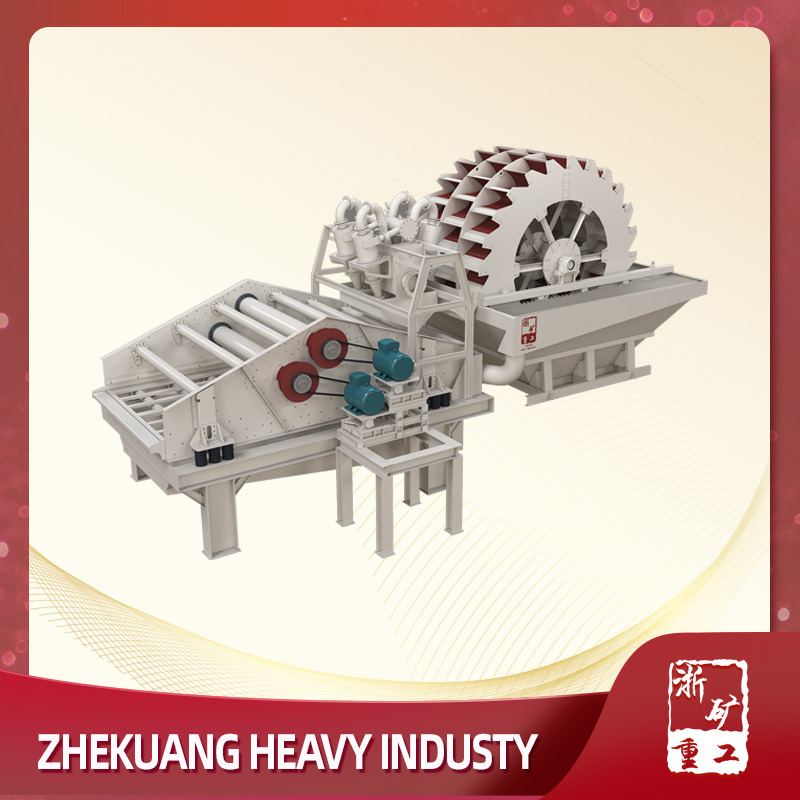

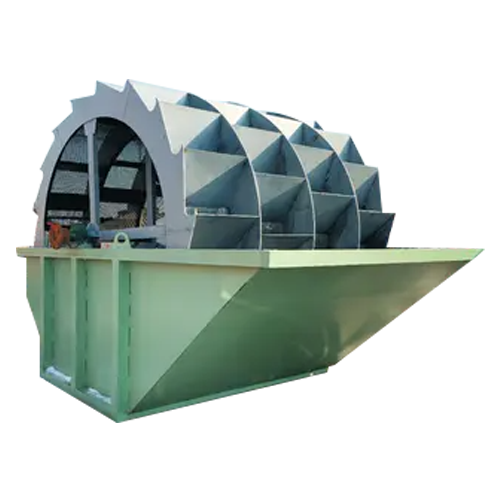

Production Introduction

This sand washing machine is an internationally advanced equipment for washing sand, gravel, and slag particles, which our company has introduced advanced technology from similar foreign products. Widely used for material washing in industries such as sand and gravel yards, mines, building materials, transportation, chemical engineering, water conservancy and hydropower, concrete mixing plants, etc.

When this type of sand washing machine is in operation, the hydraulic system drives the hydraulic motor to drive the wheel bucket to rotate. The sand and gravel are fed into the washing tank through the feeding tank, and after being washed and dehydrated by the wheel bucket, they are sent to the dewatering screen for dehydration. At the same time, impurities in the sand and gravel are discharged through the outlet of the washing tank, completing the cleaning and dehydration work of the sand and gravel.

Performance Characteristics

1. The structure of the machine is simple, and the impeller rotation bearing device is isolated from water and water receiving materials, greatly avoiding the phenomenon of bearing damage caused by immersion, sand, and pollutants.

2. This sand washing machine (fine yarn machine) has obvious advantages compared to traditional spiral sand washing machines when used for sand and gravel washing in sand and gravel fields, as follows:

a. The loss of fine sand and stone powder is minimal, and the gradation and fineness modulus of the washed construction sand meet the national standards of "Construction Sand" and "Construction Pebble and Crushed Stone".

b. This machine has almost no vulnerable parts except for the sieve.

c. Long service life, no need for maintenance for a long time.

Technical Parameter

|

Model |

Wheel bucket diameter(mm) |

Speed (r/min) |

Motor power(kw) |

Total weight(kg) |

External dimensions(L*W*H)(mm) |

Dehydration screen |

Passing quantity(t/h) |

|

LSX6000 |

6000 |

0-2 |

22.4-66.4 |

24000 |

9600×6100×6300 |

ZJS2222 |

260-750 |

|

LSX6000 |

6000 |

0-2 |

22.4-110.4 |

31277 |

9600×6100×6300 |

ZJS2626 |

300-800 |

|

LSX8000 |

8000 |

0-2 |

374-81.4 |

28000 |

11600×8500×7400 |

ZJS2622 |

400-1000 |

图片1.png)