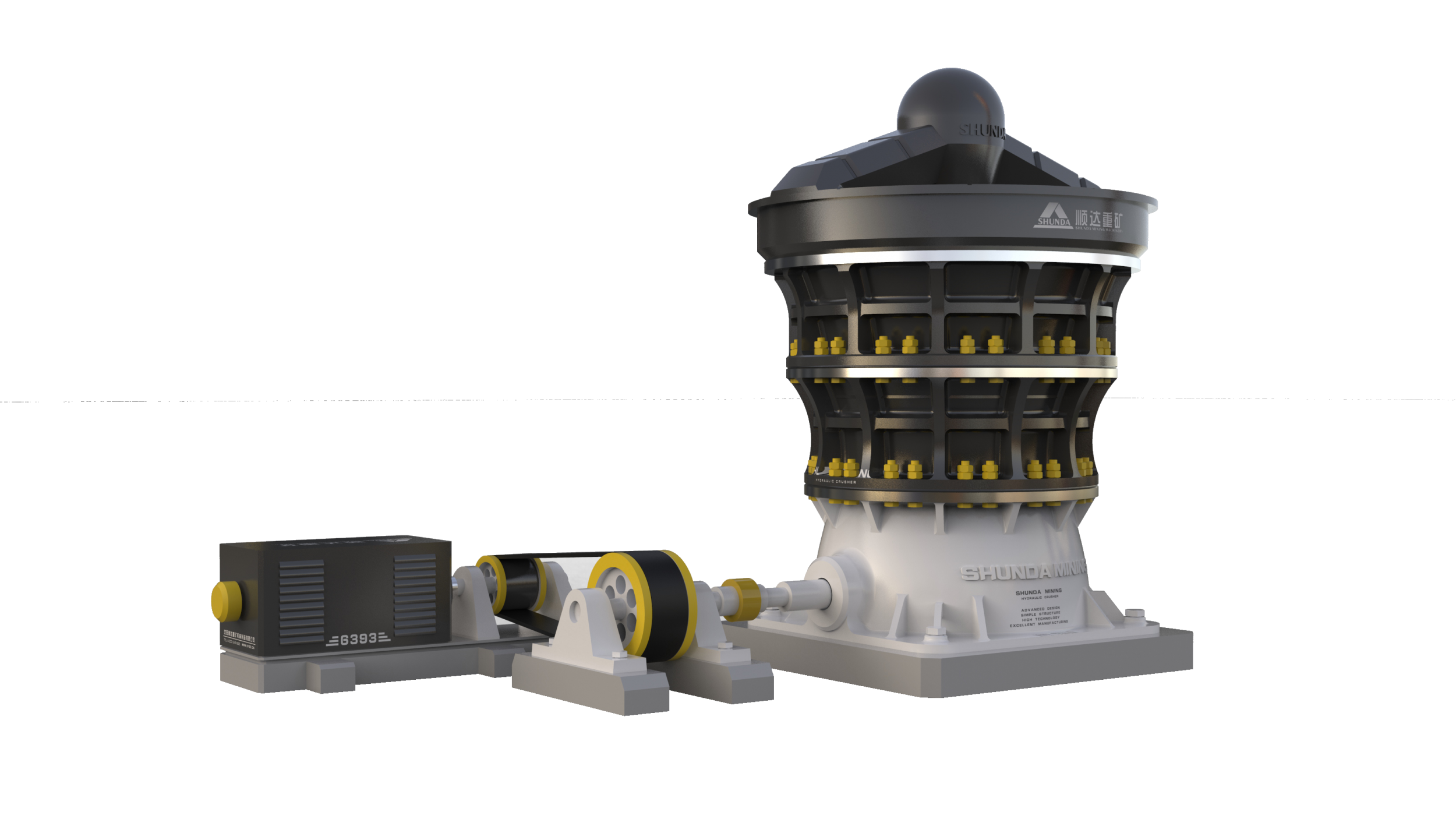

The rotary crusher is suitable for primary crushing of various rocks and ores. Compared to other primary crushing equipment, it has the characteristics of large processing capacity, high crushing efficiency, large crushing ratio, uniform product particle size, low energy consumption, and uniform wear inside the crushing chamber, making it suitable for use in large-scale production conditions.

① The hydraulic rotary crusher developed and produced by our company has a large inclination angle crushing chamber and a longer crushing surface, achieving continuous crushing, larger output, and higher efficiency.

② The lining plate made of special materials endows the crusher with strong crushing ability, resulting in a longer lifespan of the lining plate. The heavy-duty frame adopts an integrated structure design for the main shaft and moving cone, avoiding loosening of the moving cone during the crushing process, ensuring a longer service life and safer and more reliable operation.

③ Adopting spiral bevel gear transmission, it has high load-bearing capacity, smooth operation, and low noise.

④ Automatic detection of discharge port size, combined with hydraulic system to achieve automatic adjustment, ensuring the stability of discharge particle size.

⑤ Equipped with iron overload protection function, the piston type accumulator and one-way valve enable the spindle to quickly lower and slowly rise when entering the crushing chamber with superhard objects, discharge superhard objects, reduce impact, and operate safely and stably.

⑥ Effective dust seal, equipped with a positive pressure blower, with no dust entering the eccentric device.

⑦ By real-time monitoring of the oil level, oil temperature, oil pressure, flow rate, and dynamic cone position in key parts of the hydraulic and lubrication system, rapid fault diagnosis can be achieved, greatly reducing the downtime of faults. Real time monitoring of transmission shaft bearing temperature, timely detection of abnormal situations, timely maintenance, and extension of bearing service life. Real time monitoring of the material level in the feeding bin to prevent material blockage and protect the safe operation of the host. With Internet function, the running status of equipment can be remotely monitored in real time, and historical data can be used for automatic analysis and process optimization.

Technical Parameter

|

Model |

Feeding port size(mm) |

Power(kW) |

Discharge port size(mm) |

Weight |

|||||||

|

Open circuit output(t/h) |

|||||||||||

|

140 |

150 |

165 |

175 |

190 |

200 |

215 |

230 |

||||

|

ZK42-65 |

1065 |

400 |

1385-1585 |

1630-1830 |

1850-2050 |

2070-2270 |

|

|

|

|

150000 |

|

ZK50-65 |

1270 |

400 |

1480-1890 |

2035-2350 |

2475-2675 |

2610-2810 |

|

|

|

|

175000 |

|

ZK54-75 |

1370 |

500 |

|

2355-2585 |

2655-2885 |

2845-3055 |

3035-3245 |

3205-3415 |

|

|

285000 |

|

ZK62-75 |

1575 |

600 |

|

2400-2620 |

2910-3130 |

3110-3330 |

3490-3710 |

3550-3770 |

|

|

352000 |

|

ZK60-89 |

1525 |

630 |

|

|

3830-4130 |

4090-4390 |

4535-4835 |

4735-5035 |

5000-5310 |

5280-5580 |

410000 |

PX旋回破√.png)