Introduction to Features

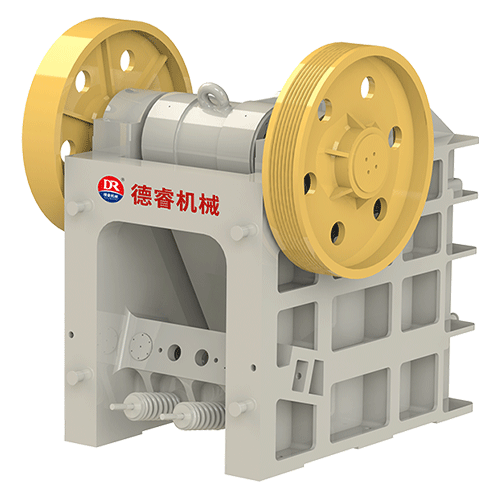

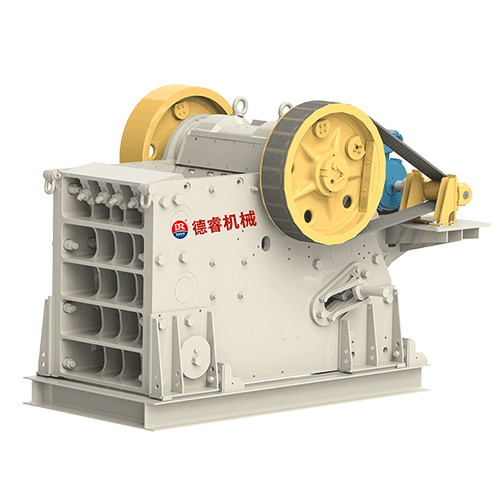

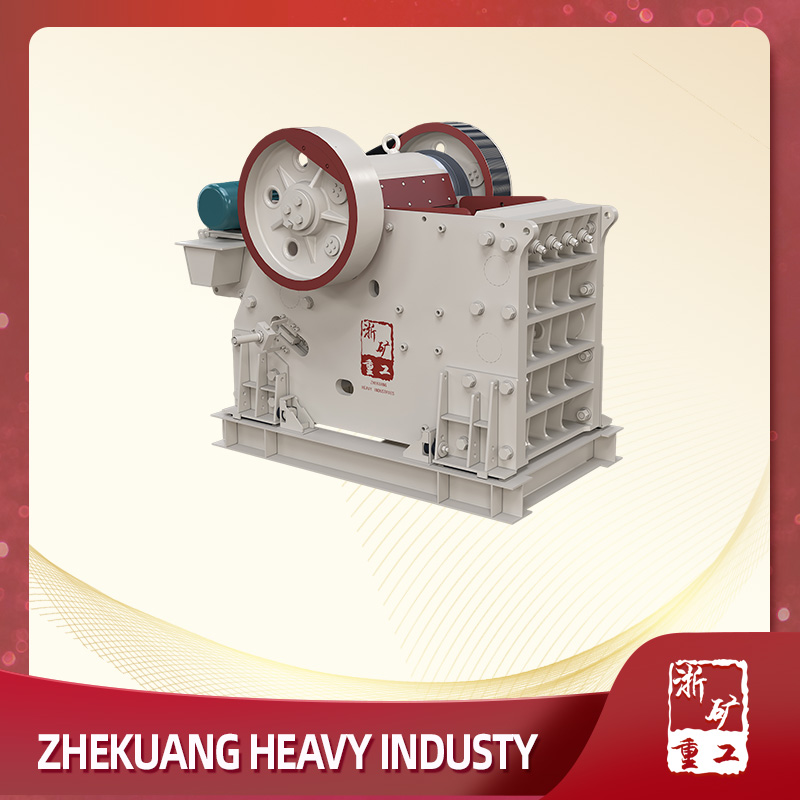

CJ series jaw crusher is widely used for primary crushing in various mines, and can crush various stone materials with a hardness not exceeding 320MPa.

1. Modular design and no welding structure make the structure lightweight and have stronger impact resistance;

2. Using high-quality bearings with large specifications for a longer and more reliable lifespan;

3. The eccentric shaft is made of heavy-duty forged alloy steel, and the front and rear frames are made of high-strength cast steel;

4. Optimized crushing mechanism achieves optimal meshing angle and stroke, improving crushing ratio;

5. Higher rotational speed increases throughput and material crushing frequency, greatly increasing production capacity;

6. Quickly adjust the discharge port, whether it is hydraulic or mechanical, it can be adjusted from both sides through wedges;

7. Easy to maintain and install, with low operating costs;

8. Can be used for various mobile crushing stations

Technical Parameter

|

Model |

Size of feed port(mm) |

Power(kW) |

Discharge port size(mm) |

Weight |

||||||||||||||

|

Open circuit output (t/h) |

||||||||||||||||||

|

40 |

50 |

60 |

70 |

80 |

90 |

100 |

125 |

150 |

175 |

200 |

225 |

250 |

275 |

300 |

||||

|

CJ80 |

800×510 |

75 |

80-105 |

100-120 |

120-155 |

145-190 |

165-215 |

190-245 |

205-270 |

265-345 |

315-405 |

365-475 |

|

|

|

|

|

12000 |

|

CJ100 |

1000×750 |

132 |

|

|

|

190-265 |

215-280 |

240-305 |

270-350 |

330-430 |

395-515 |

465-600 |

525-680 |

|

|

|

|

25000 |

|

CJ110 |

1100×850 |

132 |

|

|

|

240-315 |

265-345 |

295-380 |

320-415 |

390-505 |

465-600 |

530-690 |

600-780 |

|

|

|

|

33600 |

|

CJ125 |

1250×950 |

160 |

|

|

|

|

|

|

365-475 |

440-570 |

515-670 |

590-765 |

665-865 |

740-965 |

815-1055 |

|

|

42500 |

|

CJ140 |

1400×1070 |

200 |

|

|

|

|

|

|

|

480-625 |

570-740 |

650-845 |

740-955 |

820-1065 |

905-1180 |

|

|

53000 |

|

CJ160 |

1600×1200 |

250 |

|

|

|

|

|

|

|

|

650-845 |

754-970 |

845-1100 |

940-1220 |

1030-1340 |

1125-1465 |

1225-1595 |

81000 |

|

CJ200 |

2000×1500 |

400 |

|

|

|

|

|

|

|

|

|

950-1240 |

1070-1390 |

1180-1540 |

1300-1540 |

1415-1840 |

1530- |

120000 |

Note: The above data is based on a density of 1.6t/m ³, A brittle material with moderate particle size that can smoothly enter the crushing chamber for feeding. The processing capacity in the table is the instantaneous maximum processing capacity, which varies according to the material properties, feeding gradation, feeding method, water and mud content, and other physical properties of the material. The discharge port is defined as the distance from the bottom of the tooth tip to the top of another jaw plate tooth tip.

复摆型鄂式破碎机2.png)