Product Introduction

At present, the vast majority of existing artificial sand production lines use wet production technology. Regardless of the type of sand washing machine used, its biggest disadvantage is that the sand (particles below 0.16mm) is severely lost during washing, and some even lose more than 20%. This not only losses production, but also seriously affects the grading of sand, causing unreasonable grading and coarse fineness modulus, greatly reducing the product quality of machine made sand. Excessive sand washing discharge can also cause environmental pollution.

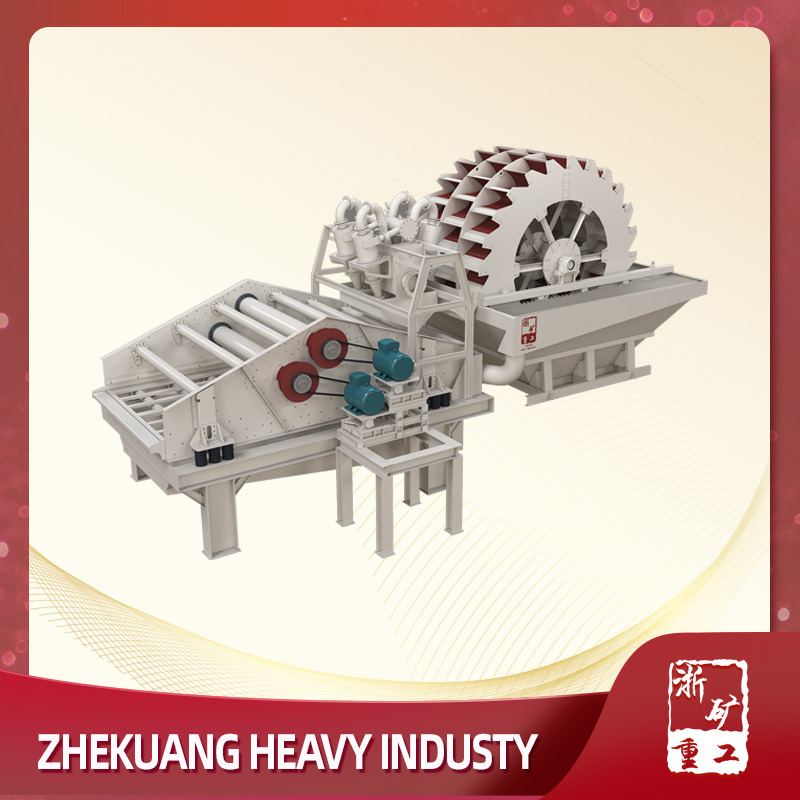

To solve the above problems, our company has developed the WS series sand washing and recovery system. This system is a world advanced fine material recovery device designed by our company to absorb advanced foreign technology and combine it with the actual situation in China. It is widely used in sand and gravel processing systems of hydropower stations, glass raw material processing systems, artificial sand production lines, coarse coal slurry recovery in coal preparation plants, and environmental protection engineering (mud purification, etc.), which can effectively solve the problem of fine sand recovery.

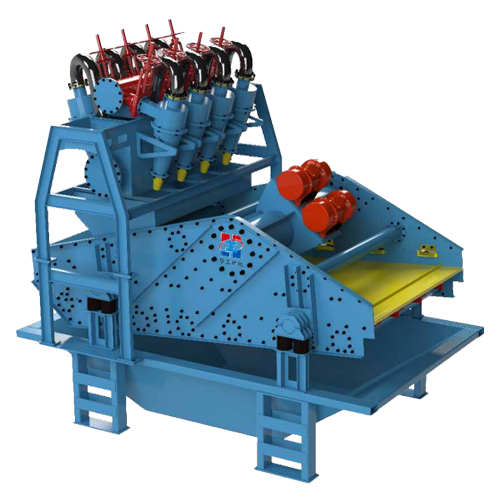

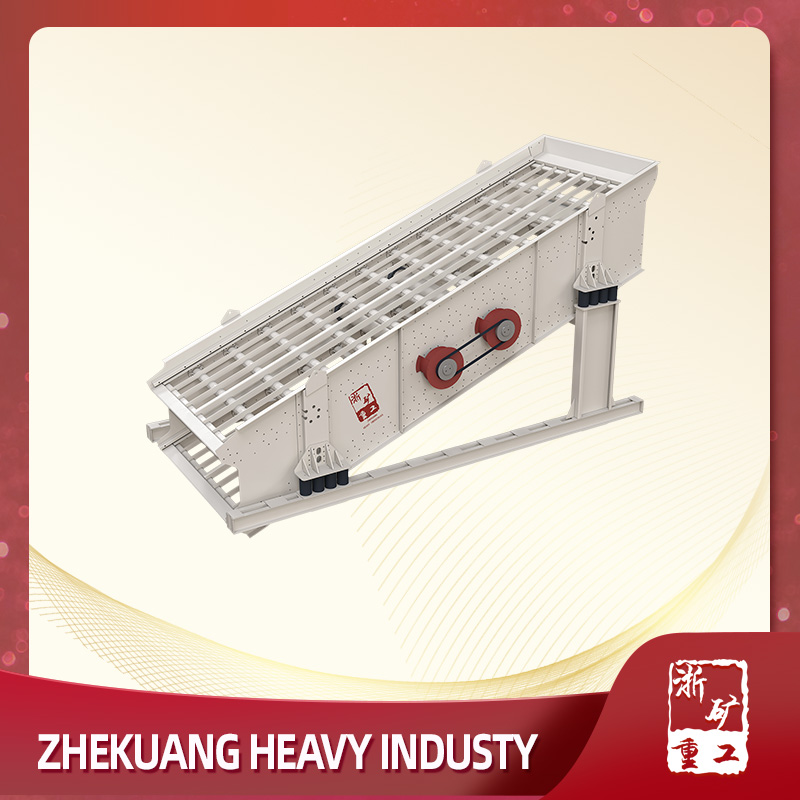

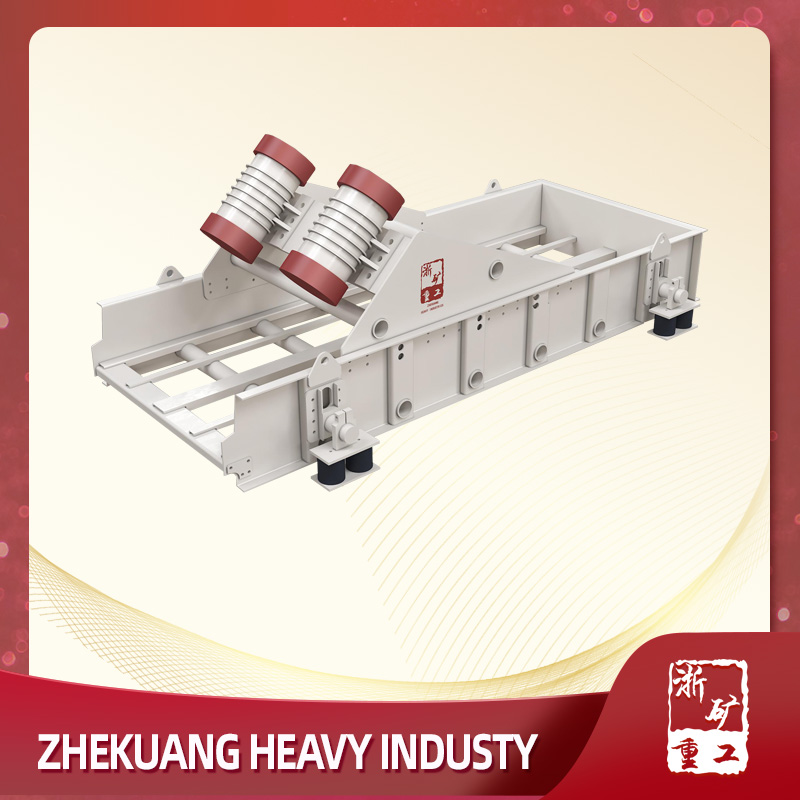

The slurry pump transports the sand water mixture to the cyclone, and the fine sand concentrated by centrifugal classification is provided to the vibrating screen through the sand settling nozzle. After being dehydrated by the vibrating screen, the fine sand and water are effectively separated, and a small amount of fine sand, mud, etc. are returned to the cleaning tank through the reverse material box. When the liquid level in the cleaning tank is too high, it is discharged through the discharge port. The weight concentration of the recovered material by the linear vibrating screen is 70% -85%. Adjusting the fineness modulus can be achieved by changing the pump speed, changing the mortar concentration, adjusting the overflow water volume, and replacing the sand outlet nozzle. Thus completing the three functions of cleaning, dehydration, and grading.

Advantages and Characteristic

1. The vibrating screen adopts polyurethane mesh, which has a longer lifespan than other types of mesh and is not easy to block holes;

2. The polyurethane inside the cyclone improves the service life of the entire device and can smoothly complete tasks such as slurry concentration and liquid clarification;

3. The sand washing and recovery system can recover 85% of the total amount of fine particulate materials emitted, which has unparalleled technological and economic advantages compared to other equipment;

4. Fine particles are fully recovered, reducing the workload of the sedimentation tank and lowering the cleaning cost of the sedimentation tank.

Technical Parameter

|

Model |

pump |

Specification fo mud and sand swparator(mm) |

Dehydration screen |

Processing capacity(m³/h) |

Weight(kg) |

|||

|

Power(kw) |

Size(inch) |

Model |

Area(㎡) |

Power(kW) |

||||

|

WS-06-300 |

11 |

2.5" |

300 |

ZJS0622 |

1.32 |

2×1 |

30-80 |

3945 |

|

WS-08-300 |

15 |

2.5" |

300 |

ZJS0822 |

1.76 |

2×1.5 |

40-100 |

4200 |

|

WS-10-350 |

18.5 |

3" |

350 |

ZJS1022 |

2.20 |

2×1.5 |

70-130 |

4900 |

|

WS-12-500 |

22 |

4" |

550 |

ZJS1232 |

3.84 |

2×3.2 |

100-220 |

7515 |

|

2WS-12-350 |

2×18.5 |

3" |

350 |

ZJS1232 |

3.84 |

2×3.2 |

140-260 |

7600 |

|

2WS-14-500 |

2×22 |

4" |

500 |

ZJS1437 |

5.18 |

2×3.7 |

200-440 |

15926 |

微信截图_20220623135131.png)

微信截图_20220623134552.png)