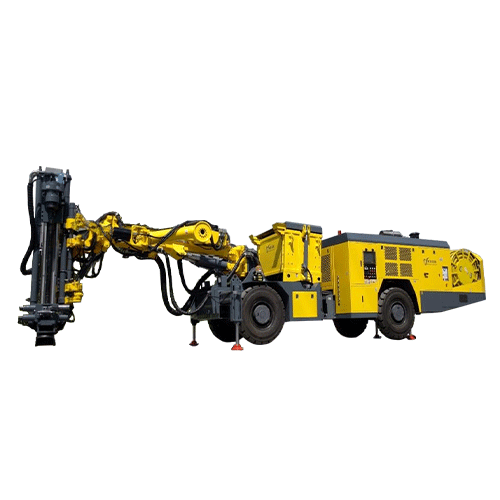

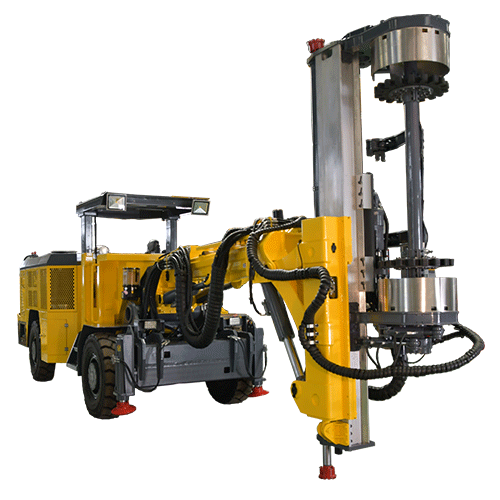

CY-MT221 ROCK DRILLING ROBOT

Conventional drilling operations in underground mines largely rely on manpower. Peopleo ften have to work under harsh conditions such as high temperature, noise, dust, water spraying, roof falling, and falling rocks, which could seriously threaten their personal safety. Rock drilling robots enable unmanned and inteligent automatic operations, which can reduce on-site workers, greatly improve mine safety and working efficiency, and lower production and operation costs.

Function Characteristics

一、Ai Artificial Intelligence Autonomous Operation System

Artificial intelligence autonomous operation intelligent operating system integrates security protection, automatic operation, fault diagnosis, data cloud storage, interconnection communication and digital display, online monitoring, control expansion and other functions, which can realize real-time access and sharing of equipment data.

二、Robot Control Technalogy

Through the research of "dynamic hole sequence planning" module, "car body positioning and coordinate conversion" module and "process control"module, the drill arm is controlled to move according to the set path, so that the position and posture of drill pipe can meet the requirements of accurately drllling the next hole, so as to realize high-precision hole drilling.

三、Big Data Rock Drilling Expert Database

Through the test of many typical rock drilling objects, the optimal parameters of hydraulic rock drill under various rock conditions are explored. The intelligent control technology based on DSP (digital signal processing) technology which can automatically adjust the working parameters according to the rock driling conditions is studied. The mathematical model and expert database of the intelligent control system are established.

Shape Dimension

|

|

A |

B |

C |

weight(t) |

|

ZY8 |

6398 |

1600 |

2311 |

7 |

性能参数

Performance Parameter

|

|

items |

unit |

value |

|

operation |

diameter |

mm |

<45 |

|

Depth |

m |

3.5 |

|

|

Angle |

° |

±180 |

|

|

Swing Speed |

rpm |

<3 |

|

|

凿岩机 |

Rated power |

|

10 |

|

impact flow |

L/min |

45~55 |

|

|

impact pressure |

bar |

100~130 |

|

|

Lubricant consumption |

g/h |

125~200 |

|

|

Lubricating gas pressure |

bar |

4~7 |

|

|

Lubricating gas flow |

L/min |

200~300 |

|

|

Flushing air pressure |

bar |

5~12 |

|

|

Flushing air flow |

L/min |

700~1200 |

|

|

Flushing water pressure |

bar |

5~12 |

|

|

Flushing water flow |

L/min |

25~40 |

|

|

travel |

Driving mode |

— |

Crawler |

|

Tuming radius |

m |

360°in place |

|

|

Driving speed |

km/h |

0~2.5 |

|

|

Gradeability |

° |

≤30 |

|

|

Ground clearance |

mm |

260 |

|

|

power |

Motor Power |

kW |

37 |

|

Voltage |

V |

standar:380 (optional:660/1000/1140) |