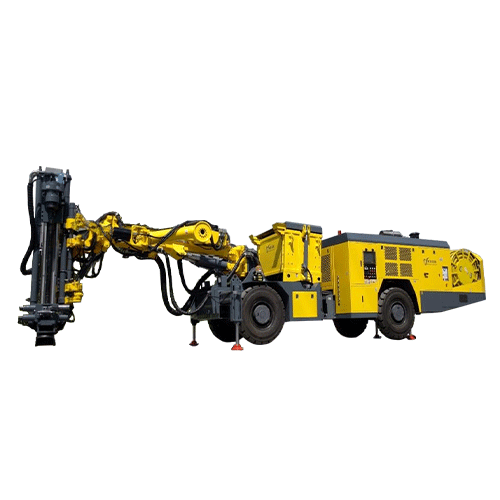

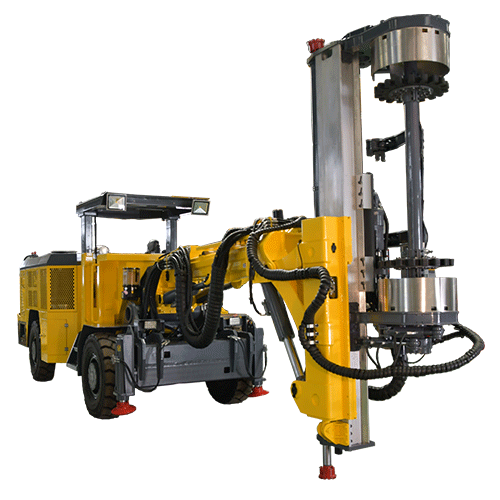

CY -T111 DRIVING JUMBO

CY-T111 face driirng rig is specialy developed by Hunan Chuangyuan to meet the development and production technalogy requirements of large, medium and small sized mines.

Adopling modular design, it can be conveniently disassembled and assembiled, and with the maximum width of only 0.98m, it can meet the requirements of down.hole operation in a small cage shaft. Driven by a diesel engine and provided with a hydraulic wheel four-wheel drive ariculated chassis and a large arm the posture of which can be adjusted during waking, it has the advanlages of smal tuming radius, sirong passing capaby, and good maneuverabilty and can walk freely in a small-section tunnel.

Wireless remote control enables more intellgent and comfortable operalion, safer and more efficient construction, and easier and more convenient maintenance, hydraulic system has automatic drill arm leveling, anti-jamming, anti-iding , and taping functions, and is applicable to boring of tunnel with a section of 3.9mx3.6m (W x H), and when provided with an inteligent conrol system of dril rig, it enables one-touch automatic full-section drilling according to the designed hole pattern and is a preferred boring equipment for small and medium sized mines to realize mechanization and intellectualization.

Function Characteristics

l.Modular design for convenient disassembly and assembly

Modular design is adopted according to the functions of the machine to realizerapid disassembly and assembly; With the maximum width of only 0.98m. it is applicable to down-hole transport insmall (W > 1m) cage shaft.

ll . High protection grade to enable more stable system operation andlonger service life of parts and components

The machine control system has automatic drilling, automatic regression,automatic anti-jamming,and automatic anti-idling functions, effectively improvingdrilling efficiency and lengthening the service life of rock drill and drilling rig; With high protection grade of electrical system and protection level of sensor notlower than IP67, it is designed for high-heat and water-rich environment and canoperate safely and reliably on a long-erm basis in water-rich, and other severeenvironment with terrestrial heat of mines.

lll. High intelligence

It can record the quantity of holes, the drilling depth, and vanous operating parareters of system in real time, and is provided wih an intelligent control system to enable one-touch automatic full-section drilling acoording to the designed hole pattern.

IV. Translational motion of mechanical double triangle arm to ensureaccuracy and reliability

Mechanical double triangle translational motion mechanism is adopted, with fullhydraulic control to enable translational motion of working mechanism, ensuringhigh reliability and realizing translational motion of drill arm in a convenient andaccurate way;

Translational motion can be relieved by one touch and arm angle can beseparately adjusted to realize drilling of oblique holes.

V. Articulated chassis, independent four-wheel drive, automatic slipproof

Articulated chassis is adopted to enable rotation of drill arm, with small turningradius to realize flexible, rapid, and safe walking in channel;

With independent four-wheel drive to provide strong power, it is able to climb a30° slope with good pavement conditions;

Four wheel motors are provided with speed sensors, and in case of differentialamong four wheels, slip-proof control system will force the four wheels to runsynchronously and strengthen the passing capability of the vehicle, and meanwhile.motor overspeed protection is realized through speed monitoring.

Job dimensions

|

A |

B |

C |

D |

E |

F |

G |

H |

|

8800 |

980 |

1730 |

14 |

14 |

2520 |

1600 |

≥280 |

Turning radius

|

θ |

r |

R |

|

34.5 |

3605 |

5500 |

Performance Parameter

|

|

items |

unit |

value |

|

参数整机 |

Weight |

Kg |

7500±200 |

|

Transport dimensions |

mm |

8800×980×1730 |

|

|

Parameters of |

Swing angle |

° |

±50 |

|

Pitch angle |

° |

±36 |

|

|

Retracting stroke |

Mm |

700 |

|

|

Righting angle |

° |

±10 |

|

|

Rotation of propelling beam |

° |

360 |

|

|

Working Parameters |

Hole diameter |

mm |

38~64 |

|

Hole depth |

m |

2.5 |

|

|

Maximum working area |

mm |

3900×3600 |

|

|

/ |

DF540L(Doofor) |

||

|

J |

185 |

||

|

HZ |

78 |

||

|

kw |

14 |

||

|

Nm |

796 |

||

|

L/min |

150 |

||

|

bar |

4~7 |

||

|

L/min |

200~300 |

||

|

Propulsion |

Drill rod |

mm |

D35 |

|

Maximum feed force |

kN |

12.5 |

|

|

Feed distance |

mm |

2500 |

|

|

Walking |

Walking speed |

Km/h |

0~5.34 |

|

lurning radius |

mm |

3605(内inner)/5500(外outer) |

|

|

Ground clearance |

mm |

280 |

|

|

Gradeability |

° |

14 |

|

|

Power |

Voltage |

V |

380 |

|

Motor power |

kW |

45 |

|

|

Motor speed |

rpm |

1480 |

|

|

Diesel engine power |

kW |

37(Cummins China IV) |