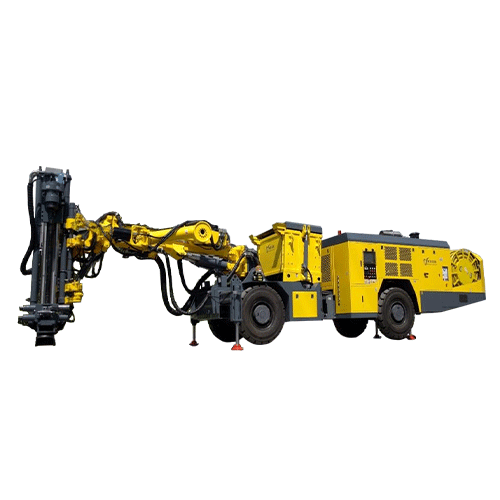

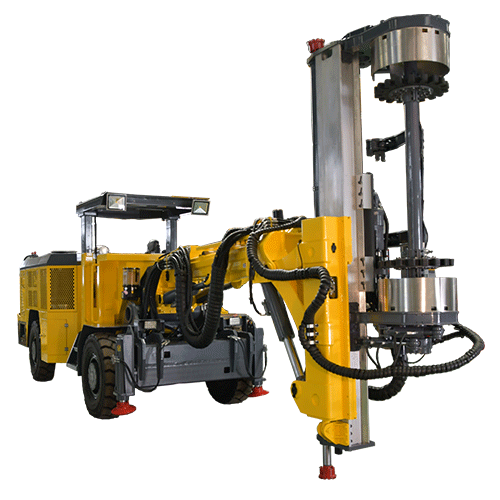

CY-R40C CUTTING GROOVE RBM

The purpose of culting groove is to create free face and provide free space for large-scale mining, and the boring of cuting groove direcly inuences continuousand balanced producton of an underaround mine. At present in China, manual boring is qeneraly adooted in cuting qroove construcion whle conventional borngwithl RBM is adopted in few mines, with safety factors, working eficiency, and environmental indicators faing to meet the requrements of production in medium tclarge sized mines, Ou pioneering CY.R40c cuting qroove RBM in China is specialy used for boin constucion of vanious cuting orooves, for which automai.down-hole operalion and transfer is possilble so that pouing of concrele foundallon is nol necessan, realzina convenient instalalon for fransfer and sale aneficient. With vanous technical indicators reaching the intermational advanced level, it can fuy meet the technological requirements of culing groove construcion in vanous underground mines of China.

Function Characteristics

SELF-LUBRICATING AND MAINTENANCE-FREE CRAWLER CHASSIS

The customized hydraulic crawler chassis are self-lubricating and maintenance-ree,canautomalically shift gears between two speeds, can travel by wireless operation on or besidethem,The rig is safe, reliable, flexible and efficient.

AUTOMATIC PRESSURE-MAINTAINING STEADY MACHINE SYSTEM

Automatic pressure-maintaining steady machine system is used to replace the concretefoundation,can keep rig a special condilion of"come and work, complete and go away".Thesystem can save much time of base pouring and machine installation.

DIESEL-ELECTRIC DUAL POWER HYDRAULIC SYSTEM

Two independent hydraulic systems with load-sensing control, constant power controlpropartional solenoid control are used. All functions of working site are powered by a motorDiesel is responsible for traveling. So the major advantages of CYRV series RBM hydraulicsystem are same with CY-R seres RBM.

RCS INTELLIGENT CONTROL SYSTEM

The CY.RV series RBM installs RCS intelligent control system with safety protection,automatic operation, fault diagnosis, data storage, Internet communications, digitaldisplay and other functions (see specification of RCS intelligent control system).

TOW DRILLING MODES AND THREE OPERATION MODES

The control system supports two driling modes(high accuracy drilling mode and fastspeed drilling mode) and three operation modes(manual operation, wireless operation andwired operation).The user can select drilling mode according to accuracy requirement andgeological conditions and select operation mode according to operating position and theactual situation.

FULL-MECHANIZED CONNECTION & BREAKOUT DRILL ROD SYSTEM

By means of the automatic positioning technology and two hydraulic wrenchesinserted dynamically, the operation that operators connect and break out drill pipes can beaccomplished without being directed.Thesystem greatly reduces working strength andsaves auxiliary working time.

OUR PATENTED TECHNOLOGY AND HIGH-LEVEL CONFIGURATION

Our large number of patented technology and numbers of intemational well-knowncomponents (such as electric paris, hydraulic parts, transmission parts) are included inthe RBM.Compared with same kinds of products,ours are more reliable and moredurable.

Product Function

Longhole drilling

Diameter Φ220mm

Depth 200m

Boxhole drilling

Diameter ф670mm

Depth 60m

Down reaming

Diameter ф670mm

Depth 60m

Down raising

Diameter ф1000mm

Depth 200m

Performance Parameter

|

|

items |

unite |

CY-R40C |

|

propulsion |

feed force |

kN |

1700 |

|

lifting force |

kN |

1700 |

|

|

feed distance |

mm |

1440 |

|

|

rotation |

nomianl torque |

kN.m |

82 |

|

peak torque |

kN.m |

95 |

|

|

rotation speed |

r/min |

Pilot Hole with a Diameter of 30 Reamed/Expanded Hole to a Diameter of 15 |

|

|

travel |

weight |

t |

25.4 |

|

travelling speed |

km/h |

0~3 |

|

|

gradeability |

° |

14 |

|

|

height from the ground |

mm |

≥200 |

|

|

power |

voltage |

V |

standard:380 |

|

motor power |

kW |

90 |

|

|

diesel engine power |

kW |

96(Cummins ChinaIV) |