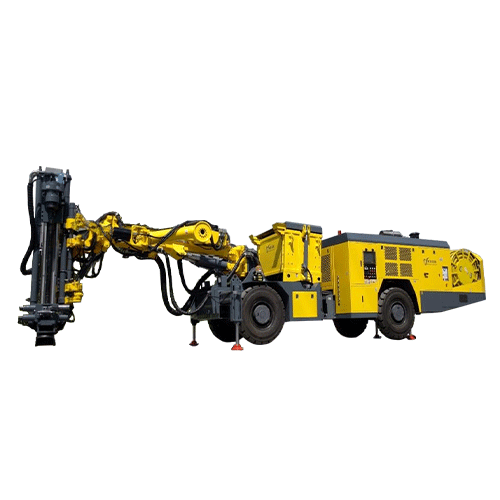

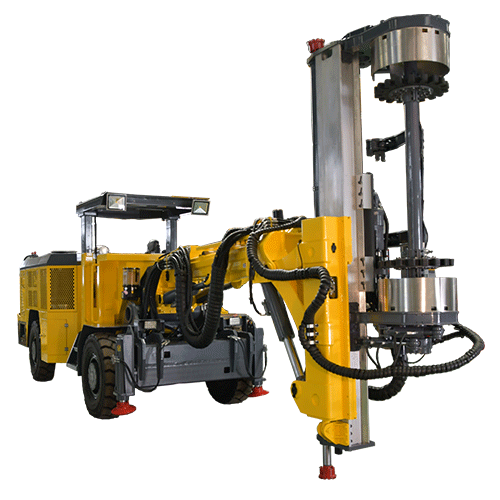

CY-MD311 INTELLIGENT UNDERGROUND IN-THE-HOLE DRILL

CY-MD311 inteligent underground down-the-hole dril is the giobal first robo-aided inteigent underground down-he-hole drllspeciay developed by Hunan Chuangyuan with creative design concept of funcional structure modularization, in combination with high-and hydrauic and robotic technologjies and based on the experience in convenional down-the-hole dill to meet the requirements of development of inteligent mines at present and in the future and those of actual production technologies.

In addition to a compact and elegant appearance, the machine adopts a strong four-wheel drive ariculated chassis and multi-functional module design, and is provided with independent creative automaic-posiioning dril rod fixture and high-end electic and hydrauic control technologies to reaize one-touch automatic operation. The machine works with a small distance to tunnel and a large ranslalional distance and can complete operation of muliple holes by one-time positioning. CY-MD311 intellent underground down-the-hole drill covers a wider range of hole diameter and depth; with more comfotable and inteligent operaion, more safe and efficient construction, and easier and more convenient maintenance, it is the preferred equipment for underground largediameter long-hole mining and the development of intelligent mines in the future.

Function Characteristics

一、INDEPENDENT AND FLEXIBLE FOUR-WHEEL DRIVE

Four-wheel hydraulic motor drives the articulated chassis separately, with flexible transfer;

二、OPTIONAL POWER AND OPERATION MODES TO REALIZE DIVERSIFIED CUSTOMIZATION

Modular power design is adopted to enable diesel-electric, battery-electric, electric-only and diesel-only modes;

Multiple operation modes, including manual, wired, and wireless operation, are available.

三、FLEXIBLE ON-BOARD COMPRESSOR WITH NO NEED FOR EXTERNAL GAS SOURCE

Sullivan on-board compressor with more stable and reliable performance is used;

The supply distance of accompanied gas source is short, with small pressure loss and more thorough slagging.

四、GLOBAL FIRST ON-BOARD INTEGRATED ROD STAND

Drill rod is more conveniently accessible;

Automatic thread lubricating oil loading system is provided to save effort in construction.

五、ROBOTIC DRILL ROD FIXTURE SYSTEM

Sliding type multi-DOF hydraulic manipulator is used to automatically complete drill rod fixture;

Double triangle telescopic dril arm is provided to realize superlarge distance of translational motion and small distance to tunnel during operation.

六、ADVANCED HYDRAULIC TECHNOLOGY, MORE ACCURATE ACTIONS, AND MORE RELIABLE OPERATION

Load sensitive, multi-filtered hydraulic system controlled by proportional solenoid valve is used to realize high energy efficlency, high intelligence, strong pollutant resistance, and high system stability and reliability;

Electric-hydraulic integration system has its valve integrated with high-performance data processing and control unit to monitor and analyze in real time various performance paramelers of the system and realize easier and more convenient construction and fault analysis.

七、PROVIDED WITH OUR RIG POSITIONING AND NAVIGATION SYSTEM AND COMMUNICATION SYSTEM, TERMINAL CONTROL SYSTEM CAN REALIZE REMOTE CONTROL BY WHICH MULTIPLE RIGS

Real-time industrial bus communication with operation response delay lower than 100ms to ensures safe, correct, and high-accuracy rig operation;

Remote operation, with more stable and reliable performance, can meet the requirements of working scenario with wide temperature range of -25℃~+70℃ and those of mine, heavy industry, and other severe environment.

Industrial display with protection grade of lP65 adopts antil-vibration structure and is applicable to high-dust, high-vibration and other severe environment.

八、AUTOMATIC OPERATION OF MULTIPLE HOLES BY ONE-TIME POSITIONING WITH NO NEED FOR MANUAL INTERVENTION

Total station and naked-eye 3D technologles are used lo realize positioning at one time and completely autonomous operation by one touch;

Robot technology is applied, by which drill rod fixture is completed by manipulator and thread lubricating oil is automatically loaded.

九、IDOS

Safety protection:Stoppage of drll rod upon malfunction, jamming warning and protection, and emergency power cutting are provided to ensure the safety of equipment and personnel;

Aulomatic positioning: Hole positioning system ls provided to realize automatic hole positioning;

Automatic self-diagnosis:System fault diagnosis module carries out timely detection and gives out timely warning and prompt;

Optimal driling: System operation data are timely acquired and checked for automatic adjustment to realize optimal drilling;

Production statement report and lithology analysis: Various parameters are displayed timely in details through wide-band communication with on-board industrial lablet PC via wifi, and production statement, equipment operation statement and relevant records are generated automatically.

Shape Dimension

|

A |

B |

C |

D |

E |

F |

G |

H |

I |

|

11759 |

2200 |

2617 |

>300 |

14 |

16 |

7050 |

4133 |

3810 |

Performance Parameter

|

|

items |

unit |

value |

|

Camplete machine parameter |

Machine weight |

t |

23.3 |

|

Transport dimensions |

mm |

11759×2200×2617 |

|

|

Working parameters |

Pressure |

MPa |

0.8~1.8 |

|

Hole diameter |

mm |

105-165 |

|

|

Hole depth |

m |

0~100 |

|

|

Angle |

° |

0~90 |

|

|

Maximum parallel hole spacing |

mm |

6000 |

|

|

Distance to tunnel |

mm |

500 |

|

|

Propulsion parameters |

Drill rod |

mm |

114/89-1500 |

|

Feed force |

kN |

0~80 |

|

|

Lifting force |

kN |

0~80 |

|

|

Total length of propulsion beam |

mm |

2700 |

|

|

Feed distance |

mm |

1866±50(1870) |

|

|

Rotation parameters |

Rated torque |

kNm |

4.5 |

|

Peak torque |

kNm |

7.2 |

|

|

Rotation speed |

rpm |

0~36 |

|

|

|

Walking speed |

km/h |

180m/min |

|

Gradeability |

° |

≥14 |

|

|

Ground clearance |

mm |

≥300 |

|

|

Turning radius |

mm |

4133(内inner)/7050(外outer) |

|

|

Tire size |

|

12.00-20 |

|

|

steering angle |

° |

±40 |

|

|

Swing angle of frame |

° |

±8 |

|

|

Power parameters |

Voltage |

V |

380V/660V/1000V |

|

Motor power |

kW |

55 |

|

|

Diesel engine power |

kW |

96(Cummins China IV) |

|

|

Air compressor |

Power |

kW |

160 |

|

Nominal volumetric flow rate |

m³/min |

18 |

|

|

Rated exhaust pressure |

bar |

18 |

|

|

Operating pressure range |

bar |

6.5~18 |

SD150F-1√.png)

SDC170√.png)

SDC130无背景√.png)