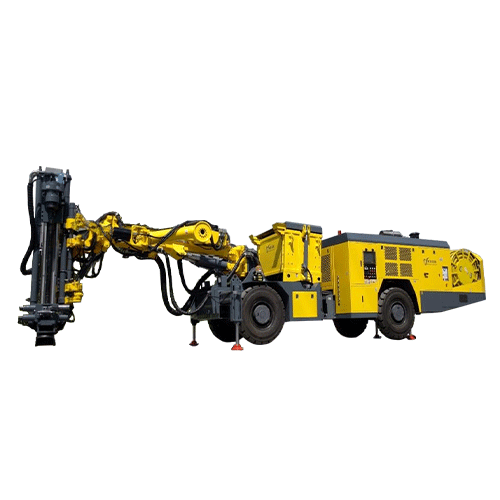

CY-MT311(智能型)地下中深孔凿岩采矿台车

CY-MT311 INTELLIGENT UNDERGMEDIUM AND DEEP HOLE ROCK DRILLING AND MINING RIG

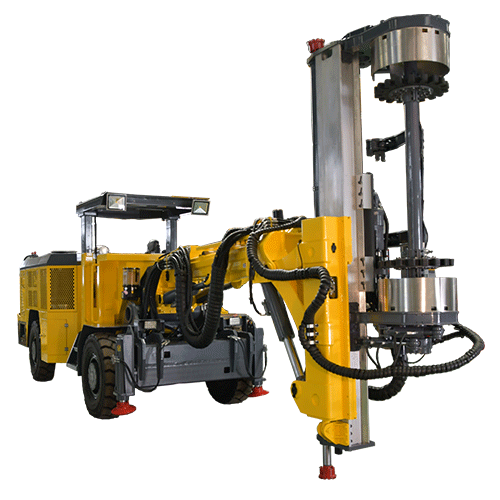

CY-MT311(智能型)地下中深孔凿岩采矿台车是湖南创远高新为满足当前及未来智慧型矿山的发展和实际生产工艺需求,在传统中深孔采矿钻机使用经验的基础上,运用创新的功能结构模块化设计理念,并搭配尖端的电液控制技术研发出来的一款适用于大、中型岩巷的智能型地下中深孔凿岩采矿台车。整机采用更现代化的外观设计,更人性化的操作界面,为操作者提供更舒适和人性化的工作环境。凿岩作业配置防卡钎系统,具备防空打、自动接卸杆及自动回退功能,有效提升钻进效率,降低钻具磨损。一次移机定位可实现在大断面巷道内自主钻凿中深平行孔,同时可在顶板及边帮上开凿作业,能满足多种定位功能的凿岩采矿钻孔需求。CY-MT311(智能型)地下中深孔凿岩采矿台车凿岩孔径覆盖范围广且孔深更深;整机操作更加舒适、智能;施工更加安全、高效;维护更加轻松、便捷,是无底柱高分段崩落采矿法及未来智慧型矿山发展的首选智能装备。

CY-T311 intelligent Under Medium and Deep Hole Rock Drling And Mining Rig is an intelligent underground medium- and deep-hole mining drill applicable for large- and medium-sized rock drifts developed by Hunan Chuangyuan High-tech Machinery Co, Ltd. to meet the needs of intelligent mines in current and future development and production operaions. lt is a product of combining the innovative functional structure modular design concepts with the cutting-edge electro-hydraulic control technology based on the applicafion history of conventional deep-hole machining drills.

With more modern appearance design and more user-friendly operaion interface, it provides operators with more comfortable and humanistic working environment. Mining operations are supported by the ani-jamming system whose ineffecive drilling prevention, automatic rod connection/disconnecion and automatic retraction functions can effectively improve drilling efficiency and reduce drilling tool wear. The machine just needs to be moved and positioned for one time before staring to drill medium or deep parallel holes in a drift with large cross-section. In addition to this, it can also work on the roofs and pit slopes, making it posible to meet the requirements of some driling and mining operations for varous positioning features. CY-T11 intelligent Under Medium and Deep Hole Rock Drilling And Mining Rig alows a wider range of hole diameter and a large depth of holes. It is more comfortable and intelligent to operate, is safer and more efficient to work, and is easier and more convenient to maintain. It is the preferred intelligent equipment for pillarless sublevel caving and development of intelligent mines in the future.

功能特点

Function Characteristics

一、四轮独立驱动,机动灵活

INDEPENDENT AND FLEXIBLE FOUR-WHEEL DRIVE

- 四轮液压马达独立驱动铰接式底盘,转场机动灵活;

Four-wheel hydraulic motor drives the articulated chassis separately, with flexible transfer;

二、多动力模块选配及多模操作,定制更加多样化

MULTIPLE POWER MODULE OPTIONS AND MULTIMODE OPERATION FOR MORE DIVERSE CUSTOMIZATION

- 动力模块化设计,快速实现柴电组合:

- 采用智能控制,多种操作模式可选,可按需选择手动、线控和无线操作方式。

Modular power design is adopted to enable diesel-electric, battery-electric, electric-only and diesel-only modes;

Intelligent control with multiple optional modes (manual, wired, and wireless).

三、自动接卸钻杆推进系统,作业更加高效

PROPULSION SYSTEM WITH AUTOMATIC DRILL ROD CONNECTION/DISCONNECTION FEATURE FOR MORE EFFICIENT OPERATION

- 轻型铝合金梁设计,高效抗弯、抗扭及抗疲劳性能,使用寿命长;

- 大容量钻杆存储系统,可满足更深孔深的凿岩作业需求;

- 自动接卸钻杆控制系统,钻杆存取更加便捷、省力;

- 配备钻杆丝扣润滑油自动加注系统,施工过程更加省心。

Lightweight aluminum alloy beam with high bending, torque, and fatigue resistance and long service life is used;

The large-capacity drill rod storage system can meet the needs of deeper drilling operations.

The automatic rod connection/disconnection control system enables more convenient and labor-saving access to drill rods.

The automatic lubricating oil filling system for drill rod threads reduces the workload inthe course of construction.

四、双三角液控平动伸缩式钻臂,大幅提升整机作业范围

DOUBLE-TRIANGLE HYDRAULIC-TRANSLATION TELESCOPIC ARM, GREATLY IMPROVING THE OPERATING RANGE OF THE COMPLETE MACHINE

- 双三角液控平动直接定位,电控全方位平动保持,凿岩孔位更加精准;

- 钻臂采用高强材料无缝套管结构设计,凿岩作业更加平稳,定位更加精准。

Direct positioning is carried out by double triangle hydraulic translational drill arm and translational motion is maintained through electric control to realize more accurate hole positions.

The arm is designed with a seamless casing structure made of high-strength materials, making rock driling operations smoother and positioning more accurate.

五、搭载IDOS钻机操作系统

- 安全保护:误动作掉杆、卡钻预警保护;应急切断动力,确保设备和人员安全;

- 自动定位:搭载钻孔定位系统,自主实现钻孔定位动作;

- 自动诊断:系统故障诊断模块适时检测,及时发出预警和提示;

- 最优钻进:系统运行作业数据适时采集和检测,自主调整,实现最优钻进:

- 上报生产报表,岩性分析:通过wifi与车载工控平板计算机宽频通信详细地适时显示各种参数,自动生成作业报表,设备运行报表和相关记录。

Safety protection: warning of misoperation-induced rod drop and rod jamming, and emergency power cutoff, ensuring the safety of eguipment and personnel;

Automatic positioning: Hole positioning system is provided to realize automatic hole positioning;

Automatic self-diagnosis: System fault diagnosis module carries out timely detection and gives out timely warning and prompt;

Optimal drilling: System operation data are timely acquired and checked for automatic adjustment to realize optimal drilling;

Production statement report and lithology analysis: Various parameters are displayed timely in details through wide-band communication with on-board industrial tablet PC vla wifi, and production statement, equipment operation statement and relevant records are generated automatically.

六、先进液压控制技术,动作更精准,运行更可靠

ADVANCED HYDRAULIC CONTROL TECHNOLOGY FOR MORE PRECISE MOVEMENTS AND MORE RELABLE OPERATIONS

- 采用负载敏感、多重过滤和全比例电磁控制的液压系统,节能高效智能化程度高,抗污能力强,系统更加稳定可靠;

- 电液控制集成系统,阀上集成高性能数据处理控制单元,可实时监控、分析系统运行的各项性能参数,施工及故障分析更加轻松、快捷。

Load sensitive, multl-filtered hydraulic system controlled by proportional solenoid valve is used to,realize high energy efficiency, high intelligence, strong pollutant resistance, and high system stability and reliability;

Electric-hydraulic integration system has its valve integrated with high-performance data processing and control unit to monitor and analyze in rea! time various performance parameters of the system and reallze easier and more convenlent construction and fault analysis.

七、一次移机定位,可完成多孔完全自主作业

START OF AUTOMATIC MULTIHOLE OPERATION, WITHOUT MANUAL INTERVENTION, BY MOVING AND POSITIONING THE MACHINE JUST ONCE

- 全站仪技术、裸眼3D技术应用,一次移机定位,一键操作完成多孔完全自主作业;

- 机器人技术应用,作业全程机械手自动接、卸钻杆,自动加注钻杆丝扣油。

Total station and naked-eye 3D technologles are used to realize positioning at one time and completely autonomous operation by one touch;

Robot technology is applied, by which drill rod fixture is completed by manipulator and thread lubricating oil is automatically loaded.

八、配置我司的钻机定位导航系统,通信系统,终控平台可实现远程控制

PROVIDED WITH OUR RIG POSITIONING AND NAVIGATION SYSTEM AND COMMUNICATION SYSTEM, TERMINAL CONTROL SYSTEM CAN REALIZE REMOTE CONTROL BY WHICH MULTIPLE RIGS

- 实时工业总线通信,低于100ms操控响应时延,确保钻机安全、准确、高精度操控;

- 远程操控器满足-25℃~+70℃宽温工作场景需求,满足矿山、重工业等恶劣现场环境需求,性能更加稳定可靠;工业显示器,IP65防护等级;防震机身设计,适用于高粉尘、高振动等恶劣工作环境。

Real-time industrial bus communication with operation response delay lower than 100ms to ensures safe, correct, and high-accuracy rig operation;

Remote operation, with more stable and reliable performance, can meet the requirements of working scenario with wide temperature range of -25℃-+70℃ and those of mine, heavy industry, and other severe environment;

Industrial display with protection grade of lP65 adopts anti-vibration structure and is applicabie to high-dust. high-vibration and other severe environment.

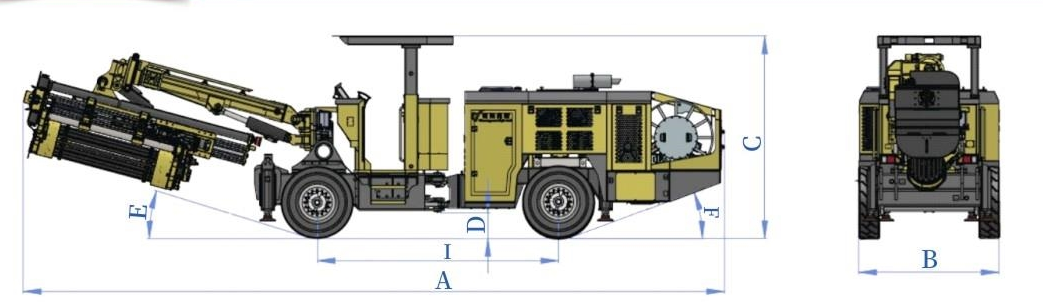

外形尺寸

Shape Dimension

| A (mm) |

B (mm) |

C (mm) |

D (mm) |

F (°) |

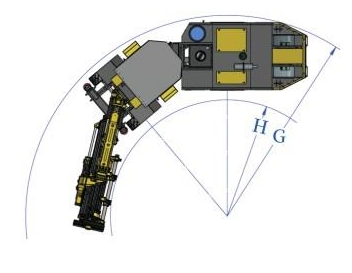

G (mm) |

H (mm) |

I (mm) |

| 11000 | 2200 | 2620-3220 | 435 | 20 | 6570 | 3805 | 3810 |

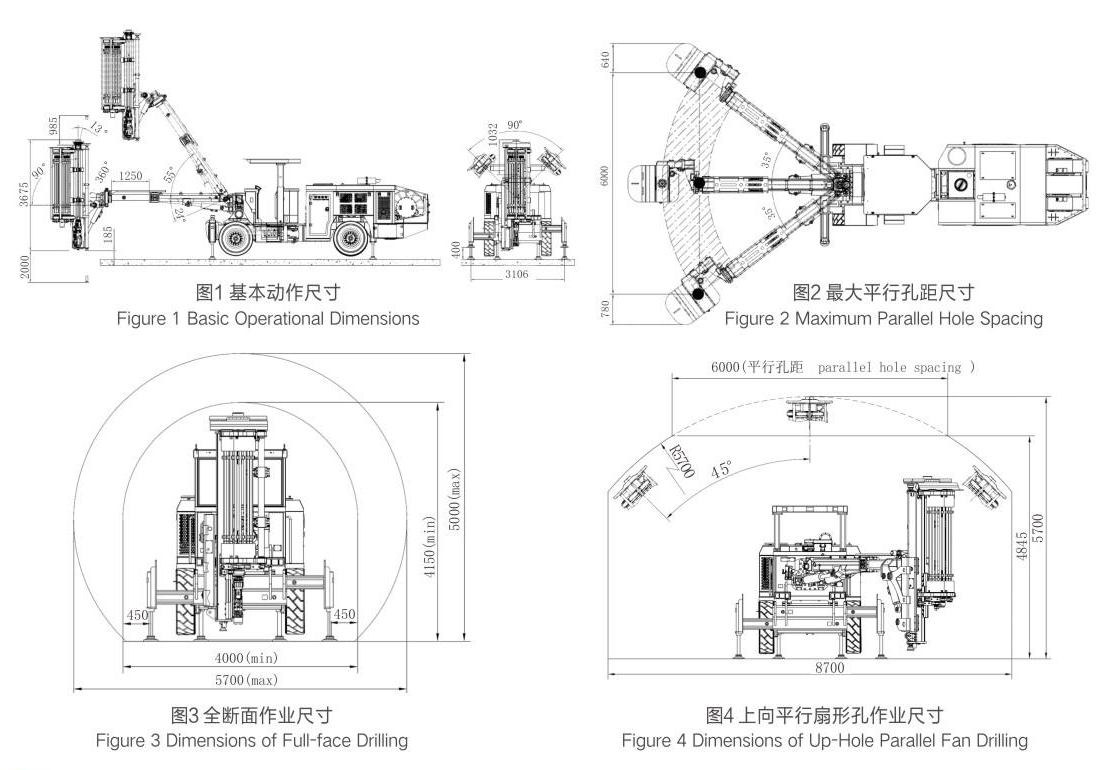

作业尺寸

Job dimensions

性能参数

Performance Parameter

| 顶目items | 单位unit | 数 值 value | |

| 参数整机 Parameters of whole machine |

整机重量 Machine weight | Kg | 20000 |

| 运输尺寸 Transport dimensions | mm | 11000×2200×2620/3220 | |

| 全断面作业尺寸(宽×高) Dimensions of full-face dilling (W×H | m | 4080×4150~5700×5000 | |

| 孔径 Hole diameter | mm | 51~89 | |

| 孔深 Hole depth | m | 32 | |

| 储杆器 Rod storage device |

钻杆长度 Rod length | m | 1.83 |

| 钻杆数量 Number of drill rods | / | 17+1 | |

| 钻臂 Drill arm |

伸缩行程 Retracting stroke | mm | 1250 |

| 最大平行孔距 Maximum parallel hole spacing | m | 6 | |

| 推进器补偿 Propeller compensation | m | 1032 | |

| 钻臂俯仰 Arm pitch | ° | 24/55 | |

| 左右偏摆 Roll | ° | 35 | |

| 凿岩机 Rock drill |

型号 Model | mm | HC95(蒙特贝) |

| 功率 Power | kW | 24 | |

| 钎尾 Shank | / | T45 | |

| 最大扭矩 Maximum torque | N/m | 764~955 | |

| 冲击功 Impact energy | J | 340~430 | |

| 供气系统 Gas supply system |

流量 Flow | m²/min | 0.7 |

| 工作气压 Working gas pressure | MPa | 0.7~1 | |

| 供水系统 Water supply system |

流量 Flow | L/min | 60~120 |

| 工作水压 Working gas pressure | MPa | 1.4~2.4 | |

| 底盘参数 Chassis parameters |

行走速度 Walking speed | km/h | 8 |

| 爬坡能大 Gradeability | ° | 20 | |

| 离地高度 Ground clearance | mm | 435 | |

| 转弯半径 Turning radius | mm | 4115(内inner)/6570(外outer) | |

| 轮胎规格 Tire size | / | 12.00-20 | |

| 转向角度 steering angle | ° | ±40 | |

| 车架摆动角度 Swing angle of frame | ° | ±8 | |

| 动力参数 Power parameters |

电压 Voltage | V | 380V/660V/1000V |

| 电机功率 Motor power | kW | 75 | |

| 柴油机功率 Diesel engine power | kW | 96(康明斯·国IV) |

UD391√.png)