<

>

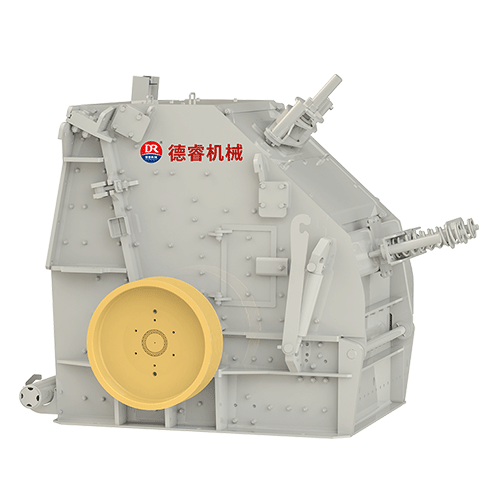

PF Series Impact Crusher

Model:

PF1214C

Size of Feeding Port:

Maximum Feed Particle Size:

<200mm

Throughput:

80-180t/h

COLLECT

CHENGDU DAHONGLI MACHINERY CO., LTD.

Main Products:Sand and gravel production line, hydraulic cone crusher, high-efficiency impact crusher, jaw crusher, impact crusher, high-pressure roller mill, vibrating sorting screen, spiral sand washing machine

Enter the store

︿

﹀

Details Parameters

Related product recommendations

More Products >

反击式破碎机.png)

PX旋回破√.png)

单缸液压圆锥破碎机2.png)

8HL.png)

复摆型鄂式破碎机2.png)

G系列高压辊磨机√.png)

水平筛√.png)

ZSW震动式给料机√.png)

圆盘给料机2.png)

LX螺旋式洗砂机√.png)

TDY带式输送机√.png)

HS-T脱水筛.png)

制砂楼√.png)

板框式压滤机.png)

袋式除尘器.png)

多缸液压圆锥破碎机.png)

123.png)