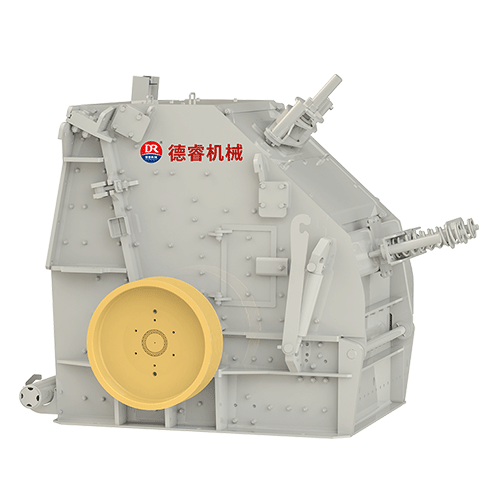

Widely used in aggregate, metal mining, chemical industries, and construction waste recycling, etc. This equipment is normally suitable for crushing materials with moderate hardness and low abrasiveness. It can be used for primary, secondary, and tertiary crushing, achieving a large reduction ratio and superior product shape.

PERFORMANCE FEATURE

- Optimized Rotor Part Design

The rotor part has been optimized to increase rotational inertia, boost equipment output, and enhance product shape. The unique wedge block hammer locking mechanism ensures easy disassembly while maintaining safety and reliability.

- Flexible Configuration

An optional third impact plate can be installed to achieve finer product sizes. Different wear-resistant hammers and impact liners are available to accommodate various application conditions.

- Hydraulic System Design

The equipment can be equipped with an efficient hydraulic system,which allows for hydraulic opening of the shell for easy maintenance and convenient adjustment of the closed side setting.

- Wear Parts Modular Design

Wear parts are well designed and arranged for maximum efficiency to minimize the varieties. They can be interchanged based on their wear levels, which enhances utilization and reducing inventory.

MAIN TECHNICAL SPECIFICATION

| Model | Feed Opening(mm) | Max. Feed Size(mm) | Rotor Diameter(mm) | Rotor Length(mm) | Power(kw) | Weight(t) |

| HFJ1213 | 1320×880 | 600 | 1200 | 1300 | 220 | 13.1 |

| HFJ1315 | 1540×930 | 600 | 1300 | 1500 | 315 | 16.6 |

| HFJ1520 | 2040×995 | 700 | 1500 | 2000 | 500 | 27.6 |

| HFJ1522 | 2240×995 | 700 | 1500 | 2200 | 630 | 31.7 |

| HFJ1313 | 1320×1200 | 900 | 1300 | 1300 | 220 | 18.4 |

| HFJ1415 | 1540×1320 | 1000 | 1400 | 1500 | 315 | 22.5 |

| HFJ1620 | 2040×1630 | 1300 | 1600 | 2000 | 500 | 41.5 |

| HFJ2023 | 2310×1980 | 1500 | 2000 | 2300 | 1000 | 75.6 |

反击式破碎机.png)