The impact crusher is mainly used for medium and fine crushing of materials. Its discharge particle size can be adjusted, with diverse crushing specifications. It boasts advantages such as a large crushing ratio and cubic-shaped crushed materials. As a crushing machine that utilizes impact energy for material crushing, during operation, the rotor rotates at high speed driven by the motor. When materials enter the plate hammer action area, they collide with the plate hammers on the rotor and are crushed, then thrown onto the impact device for re-crushing. Subsequently, they bounce back from the impact liner to the plate hammer action area for further crushing. This process repeats: materials enter the first, second, and third impact chambers in descending order of size, undergoing repeated crushing until they reach the required particle size and are discharged through the discharge port. Adjusting the gap between the impact frame and the rotor can alter the discharge particle size and shape of the materials.

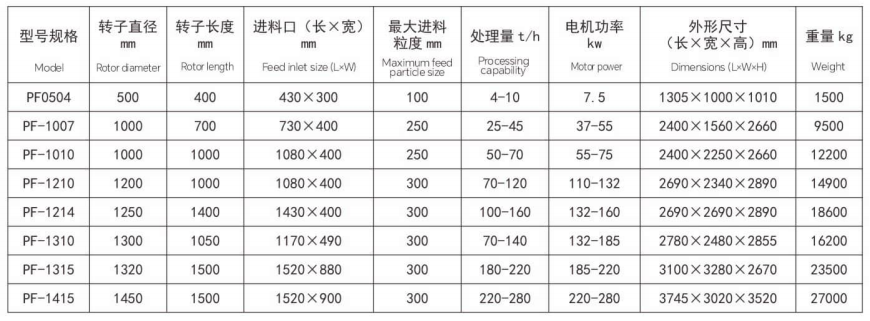

Main models and technical parameters

反击式破碎机.png)

反击式破碎机.png)

反击式破碎机3.png)

反击式破碎机3.png)

反击式破碎机1.png)