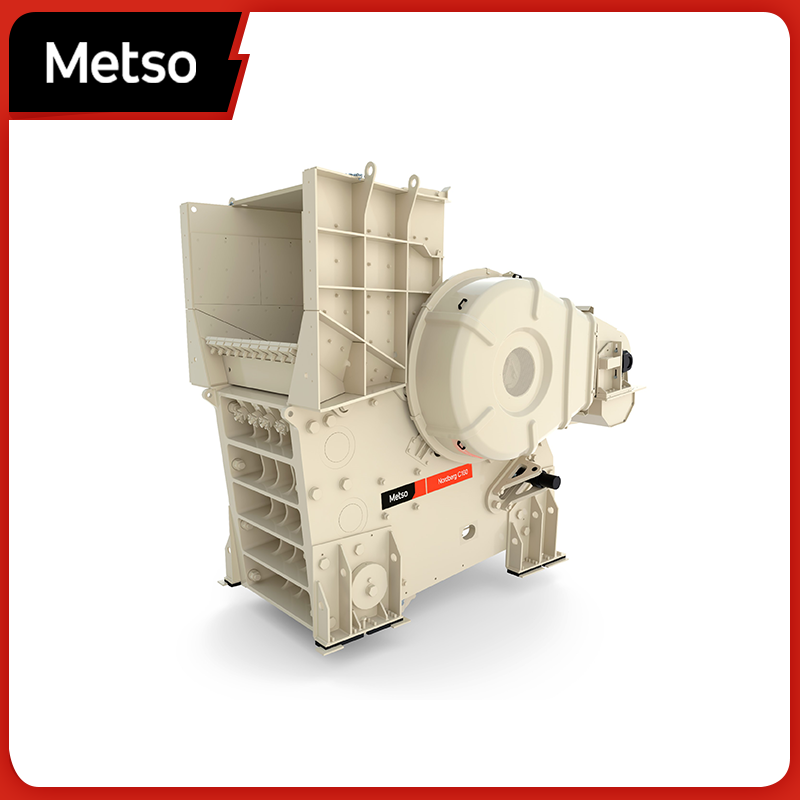

Nordberg® GP™ Series cone crushers are designed to efficiently, reliably, and economically crush feed materials into the desired final product. Engineered for all rock types, Nordberg® GP™ Series cone crushers serve as secondary, tertiary, and quaternary crushers in aggregate production and mining operations.

Capable of Crushing All Rock Types

Nordberg® GP™ Series cone crushers are widely used in aggregate production and mining operations.

In addition to stationary models, many Nordberg® GP™ Series cone crushers are also available in mobile and portable configurations.

Product Features

1. Long-Term Stable Performance

Whether high reduction ratios, high-quality cubical products, or high throughput are required, Nordberg® GP™ Series cone crushers are the optimal choice.

Compared to cone crushers of the same size (head diameter), the optimized casting design of Nordberg® GP™ Series allows for higher rated power. The crushing chamber design ensures maximum throughput for producing high-quality final products. Adjustable eccentricity and crushing chamber profiles allow easy tuning of the crusher’s throughput to match other equipment.

The steep cone angle ensures trouble-free operation under various feed conditions while delivering high reduction ratios. Continuous process and crusher control contribute to high uptime and maximum production of the desired final product.

2. Exceptional Reliability

Nordberg® GP™ Series cone crushers feature a simple yet robust two-point supported main shaft design, ensuring high mechanical reliability.

Additionally, an automated system can be integrated to continuously monitor crusher load and operational parameters, ensuring optimal performance and maximum uptime.

Our renowned metallurgical expertise, along with continuous advancements in manganese materials, metallurgical compounds, and geometric design, guarantees the reliability of Nordberg® GP™ Series cone crushers in demanding crushing applications.

3. Versatile Applications

Thanks to the ability to modify crushing chamber profiles, eccentricity, horizontal shaft speed, and control methods, Nordberg® GP™ Series cone crushers can adapt to any specific production requirements.

Adjustable eccentricity simplifies throughput tuning to coordinate with other equipment. It also allows the crusher to achieve optimal choke-fed conditions and the best discharge setting, ensuring maximum throughput for the desired final product size.

On the other hand, crusher automation ensures smooth process adaptability, enables fully automated crushing processes, and guarantees operation at peak performance levels.

4. Easy Installation, Operation, and Maintenance

Nordberg® GP™ Series cone crushers are designed for easy maintenance and servicing.

Durable and optimized components prolong the crushers’ service life, and when maintenance is required, heavy components can be disassembled from the top and lifted out.

The low installation height of Nordberg® GP™ Series cone crushers reduces the need for large supporting structures and shorter conveyors, lowering installation costs. These advantages also make them excellent solutions for portable and mobile applications.

Crusher automation enables remote adjustments for Nordberg® GP™ Series cone crushers, reducing risks and enhancing on-site personnel safety.

Nordberg® GP™ Series Cone Crushers Technical Specifications

|

Model |

Crushing Rang |

Weight* |

Power |

Maximum Feed Opening |

Optional Eccentricity |

Maximum Capacity |

|

Nordberg® GP100™ |

Medium crushing, fine crushing, ultra-fine crushing |

6 200 kg(13 700 lbs) |

75 - 90 kW(100 - 125 hp) |

135 mm(5 5/16") |

16, 20, 25 mm(5/8, 13/16, 1") |

105 Mtph(116 Stph) |

|

Nordberg® GP100S™ |

Medium crushing |

7 700 kg(17 000 lbs) |

75 - 90 kW(100 - 125 hp) |

236 mm(9 19/64") |

16, 20, 25 mm(5/8, 13/16, 1") |

250 Mtph(275 Stph) |

|

Nordberg® GP220™ |

Medium crushing, fine crushing, ultra-fine crushing |

11 100 kg(24 470 lbs) |

132 - 220 kW(175 - 300 hp) |

204 mm(8 1/32") |

18, 25, 28, 32, 36, 40 mm(11/16, 1, 1 7/64, 1 ¼, 1 13/32, 1 9/16") |

310 Mtph(341 Stph) |

|

Nordberg® GP330™ |

Medium crushing, fine crushing, ultra-fine crushing |

16 600 kg(36 600 lbs) |

250 - 315 kW(325 - 425 hp) |

215 mm(8 15/32") |

18, 22, 25, 28, 32, 36, 40 mm(11/16, 7/8, 1, 1 7/64, 1 ¼, 1 13/32, 1 9/16") |

420 Mtph(462 Stph) |

|

Nordberg® GP300S™ |

Medium crushing |

17 100 kg(37 700 lbs) |

132 - 250 kW(175 - 350 hp) |

320 mm(12 19/32") |

18, 22, 25, 28, 32, 36 mm(11/16, 7/8, 1, 1 7/64, 1 ¼, 1 13/32") |

480 Mtph(528 Stph) |

|

Nordberg® GP550™ |

Medium crushing, fine crushing, ultra-fine crushing |

28 700 kg(63 300 lbs) |

250 - 400 kW(325 - 500 hp) |

235 mm(9 1/4") |

25, 28, 32, 36, 40, 45 mm(1, 1 7/64, 1 ¼, 1 13/32, 1 9/16, 1 25/32") |

575 Mtph(633 Stph) |

|

Nordberg® GP500S™ |

Medium crushing |

34 300 kg(75 600 lbs) |

200 - 355 kW(275 - 475 hp) |

392 mm(15 7/16") |

18, 25, 28, 32, 36, 40 mm(11/16, 1, 1 7/64, 1 ¼, 1 13/32, 1 9/16") |

860 Mtph(946 Stph) |

Cone Crusher Parts and Services

1. Cone Crusher Parts

We provide a comprehensive range of crusher spare parts compatible with Metso, Nordberg®, and Symons crushers, as well as third-party crushers.

2. Crushing Chamber Optimization

Every crushing process is unique, and its performance is influenced by multiple factors.

3. Crushing Chamber Expert Services

Optimizing crushing processes and maximizing profitability from equipment are key goals for every aggregate producer.

4. Crusher Services

Minimize maintenance downtime, increase production, reduce cost per ton, or meet specific crushing requirements.

5. Lifecycle Services

Metso offers bundled and customized service portfolios to deliver support right at your doorstep.

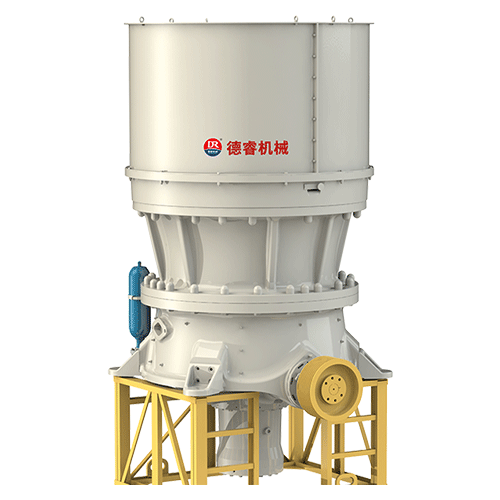

单缸液压圆锥破碎机2.png)