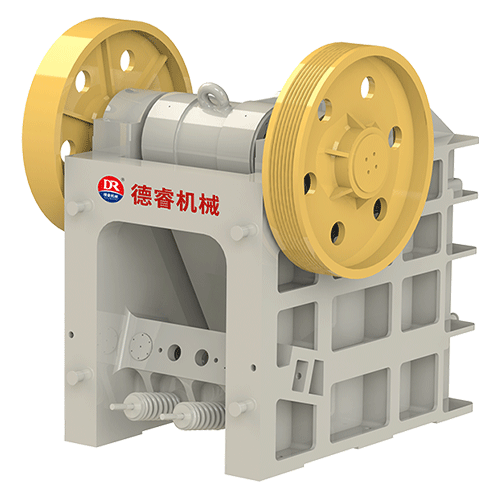

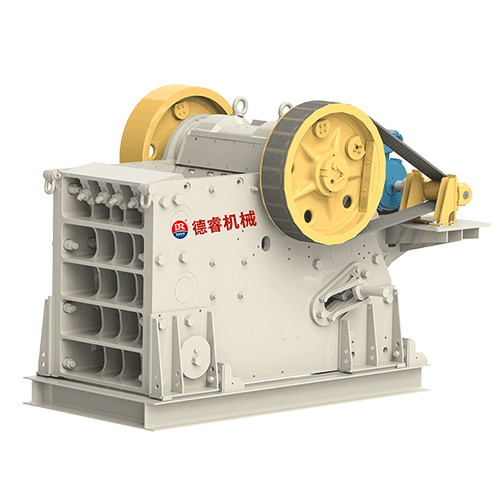

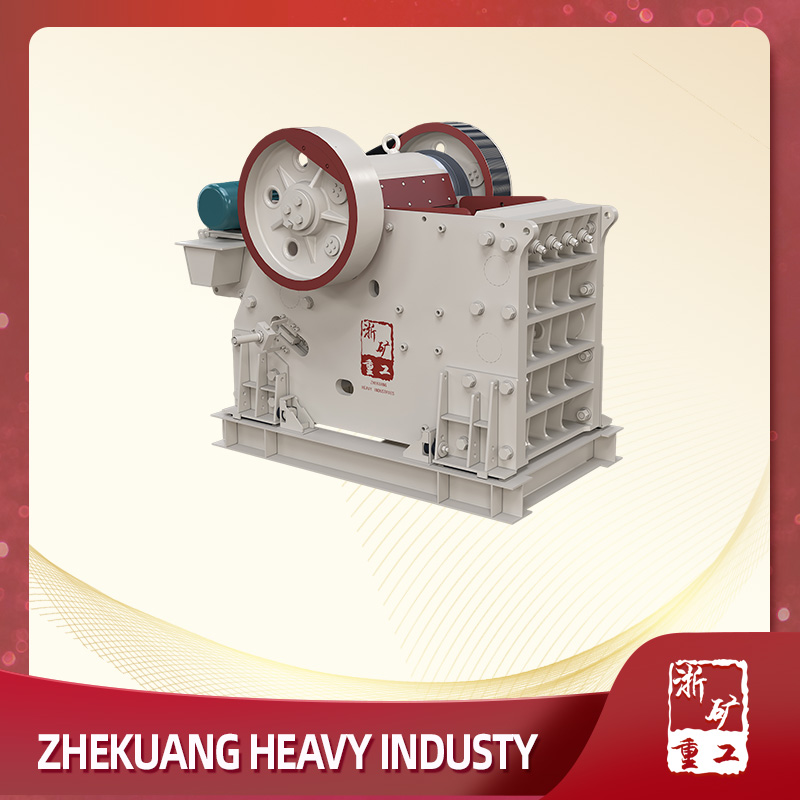

Jaw crushers are mainly used as primary crushers, designed to break rock into smaller sizes for processing in subsequent crushing stages.

Originally developed for crushing the hardest ores and rocks, jaw crushers deliver superior performance in general applications.

Capable of efficiently processing large volumes of hard rock, jaw crushers are a popular alternative to primary gyratory crushers. Due to their compact size, they are also well-suited for confined spaces, such as underground mining and mobile crushing applications.

Over 11,000 units installed

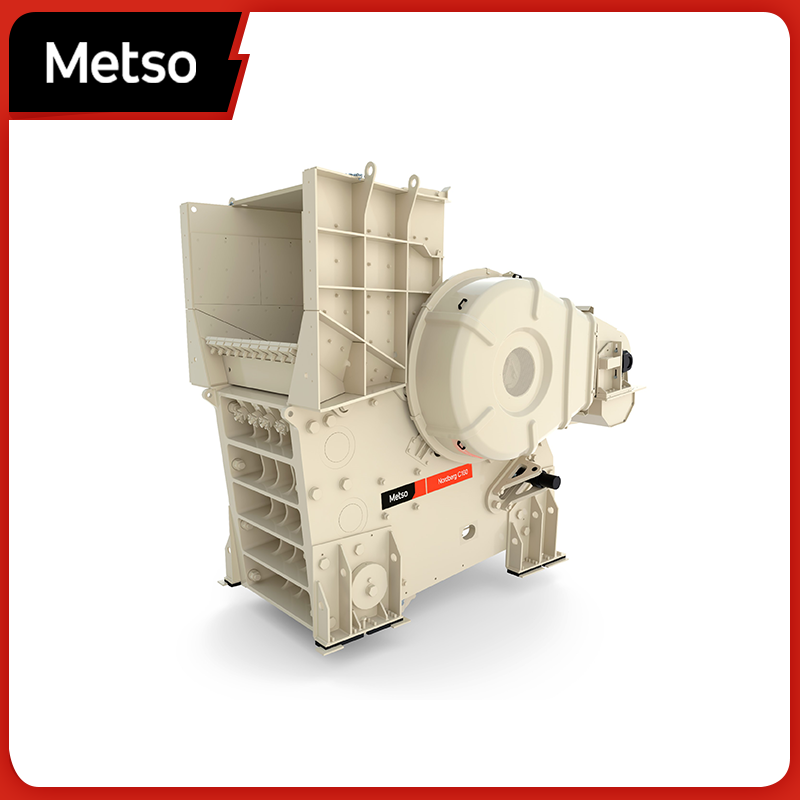

Nordberg® C™ Series jaw crushers have proven their reliability and high productivity in thousands of mining, quarrying, recycling, and industrial applications.

In addition to stationary jaw crushers, a range of mobile or wheel-mounted jaw crushing plants is available.

Product Features

1. Unmatched Reliability

The reliability of Nordberg® C™ Series jaw crushers is based on a pinned and bolted, non-welded frame construction, ensuring excellent fatigue strength. All frame components are cast from Metso's proprietary alloys specifically developed for jaw crushers.

Beyond solid casting, the frame of Nordberg® C™ Series jaw crushers features a cellular structure, proven to be sturdier and more durable.

- Pinned and bolted, non-welded frame construction

- Superior fatigue resistance

- Premium casting process

- High-quality components

2. High Productivity and Crushing Ratio

Nordberg® C™ Series jaw crushers feature an optimized movable jaw stroke and a large eccentric throw at the bottom of the crushing chamber.

A larger feed opening increases material intake and ensures smooth rock entry into the crushing chamber. A steeper nip angle reduces jaw plate liner wear, lowering operating costs and ensuring fast downward material flow in the chamber.

The eccentric throw increases from the top to the bottom of the crushing chamber. The greater stroke at the bottom enhances capacity and crushing ratio, ensuring high productivity across various applications.

- Exceptional feed intake

- Steep crushing chamber for optimal nip angle

- Efficient jaw movement for maximum capacity and crushing ratio

3. Easy Installation, Operation, and Maintenance

Nordberg® C™ Series jaw crushers feature a modular design, reducing installation time and costs. Installation can be completed within days, minimizing on-site engineering and fabrication.

An optional IC10C automation system can upgrade Nordberg® C™ Series jaw crushers for remote monitoring and adjustment of the feeder, crusher, and conveyor. This enables remote crusher operation for easier and safer handling.

Based on extensive field experience and customer testing, critical areas of Nordberg® C™ Series jaw crushers are wear-protected. Wear parts and components are designed for easy access and replacement.

- Easy retrofit on existing crushers

- Optional remote monitoring, automation, and discharge setting adjustment

- Splittable for transport

4. Multiple Optional Extras

Nordberg® C™ Series jaw crushers can be customized for specific applications. Safe flywheel and drive guards protect operators from moving parts. An optional integrated motor base allows direct mounting of the drive motor at the rear of the crusher.

- Additionally, an optional feed chute ensures consistent feeding.

- Standard jaw plates, cheek plates, and lifting tools

- Optional flywheel and drive guards

- Optional maintenance platforms

- Safe, fast, and convenient discharge adjustment system

- IC™ crusher automation system

Nordberg® C™ Series Jaw Crushers Technical Specifications

| Model | Power | Rotational speed | Weight of Crusher (Basic Configuration)* | Weight of Crusher (Operational)** |

| Nordberg® C80™ | 75 kW (100 hp) | 350 rpm | 7 650 kg (16 870 lbs) | 9 340 kg (20 590 lbs) |

| Nordberg® C96™ | 90 kW (125 hp) | 330 rpm | 10 150 kg (22 380 lbs) | 12 260 kg (27 030 lbs) |

| Nordberg® C106™ | 110 kW (150 hp) | 280 rpm | 15 650 kg (34 502 lbs) | 18 510 kg (40 810 lbs) |

| Nordberg® C116™ | 132 kW (175 hp) | 260 rpm | 19 240 kg (42 420 lbs) | 22 470 kg (49 540 lbs) |

| Nordberg® C120™ | 160 kW (200 hp) | 230 rpm | 27 990 kg (61 710 lbs) | 31 690 kg (69 860 lbs) |

| Nordberg® C130™ | 185 kW (250 hp) | 220 rpm | 40 150 kg (88 516 lbs) | 46 300 kg (102 070 lbs) |

| Nordberg® C150™ | 200 kW (300 hp) | 220 rpm | 50 950 kg (112 330 lbs) | 59 440 kg (131 100 lbs) |

| Nordberg® C160™ | 250 kW (350 hp) | 220 rpm | 76 300 kg (168 213 lbs) | 87 260 kg (192 400 lbs) |

| Nordberg® C200™ | 400 kW (500 hp) | 200 rpm | 124 000 kg (273 373 lbs) | 147 110 kg (324 320 lbs) |

| Model | Power | Feed Opening, Width x Depth*** | Throughput with Pre-Screening of Coarse Material and at Maximum Discharge Opening | Throughput without Pre-Screening of Coarse Material and at Maximum Discharge Opening |

| Nordberg® C80™ | 75 kW (100 hp) | 800×510 mm (32”× 20”) | 335 Mtph (370 Stph) | 514 Mtph (575 Stph) |

| Nordberg® C96™ | 90 kW (125 hp) | 930×580 mm (37”× 23”) | 390 Mtph (430 Stph) | 592 Mtph (662 Stph) |

| Nordberg® C106™ | 110 kW (150 hp) | 1060×700 mm (42”× 28”) | 500 Mtph (560 Stph) | 760 Mtph (850 Stph) |

| Nordberg® C116™ | 132 kW (175 hp) | 1150×760 mm (45”× 30”) | 520 Mtph (580 Stph) | 800 Mtph (880 Stph) |

| Nordberg® C120™ | 160 kW (200 hp) | 1200×870 mm (47”× 34”) | 540 Mtph (600 Stph) | 800 Mtph (880 Stph) |

| Nordberg® C130™ | 185 kW (250 hp) | 1300×1000 mm (51”× 39”) | 831 Mtph (915 Stph) | 1 267 Mtph (1 416 Stph) |

| Nordberg® C150™ | 200 kW (300 hp) | 1400×1200 mm (55”× 47”) | 880 Mtph (970 Stph) | 1 319 Mtph (1 474 Stph) |

| Nordberg® C160™ | 250 kW (350 hp) | 1600×1200 mm (63”× 47”) | 1 145 Mtph (1 260 Stph) | 1 909 Mtph (2 133 Stph) |

| Nordberg® C200™ | 400 kW (500 hp) | 2000×1500 mm (79” × 59”) | 1 435 Mtph (1 575 Stph) | 2 462 Mtph (2 752 Stph) |

复摆型鄂式破碎机2.png)