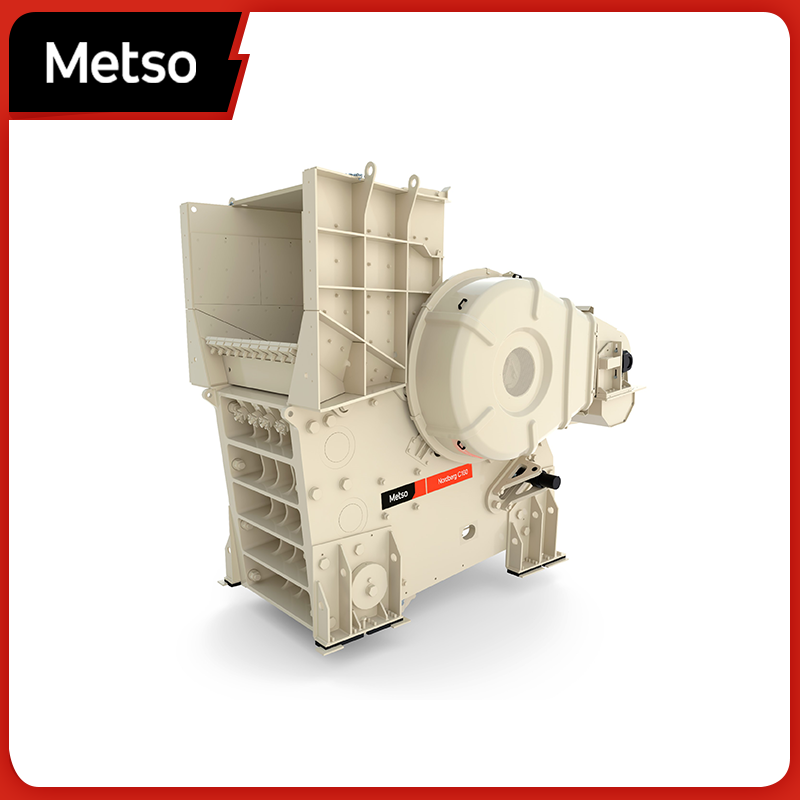

Primary Gyratory Crushers serve as the initial driving force for the entire mineral processing circuit.

Our range of primary gyratory crushers is named Superior™ MKIII Primary Gyratory Crusher, where "MKIII" represents the third generation of Superior™ primary gyratory crushers. Metso has over 100 years of experience in designing and manufacturing crushers.

The latest Superior™ MKIII Primary Gyratory Crusher outperforms its predecessors in quality, efficiency, safety, and simplicity, specifically developed to meet customers' needs in the face of fluctuating ore grades and operating conditions.

Product Features

1. Higher Throughput

Superior™ MKIII Primary Gyratory Crusher incorporates cutting-edge technology to achieve higher rotational speeds, increased installed power, and mechanical enhancements, resulting in throughput improvements of up to 30%. With its superior capacity, it stands as the most cost-effective primary gyratory crusher investment in the industry.

2.Reduced Maintenance Downtime

During the development of the Superior™ MKIII Primary Gyratory Crusher, several key improvements were implemented. After extensive R&D, a new frame and concave liner design were introduced. These advancements reduce maintenance downtime by up to 70%. The decreased crusher maintenance downtime also significantly reduces the volume of coarse stockpiles.

3.Advanced Automation System

All Superior™ MKIII Primary Gyratory Crushers can be equipped with the SmartStation system, which integrates innovative monitoring tools such as VisioRock® and VisioTruck®, along with additional sensors installed on equipment, bins, and hoppers. This enables intelligent measurement and automated control of crushing operations, optimizing ore processing and blending. The system includes online analysis and detailed reporting of plant operations.

4.Simple and Safe Maintenance

Maintenance of the Superior™ MKIII Primary Gyratory Crusher is effortless and safe. The hydraulic separation system for the frame and integrated lifting features provide a superior working environment for on-site maintenance personnel. The SmartStation system further enhances operational safety while offering better insights into maintenance requirements and predicting routine servicing needs.

Superior™ MKIII Primary Gyratory Crusher Technical Specifications

Superior™ MKIII Primary Gyratory Crusher is available in multiple models to meet your crushing needs.

|

Model |

Weight |

Installed Power |

Feed opening |

Maximum capacity |

|

Superior™ MKIII 42-65 |

120 000 kg (264 600 lbs) |

450 kW (600 hp) |

1066 mm (42") |

5 250 Mtph (5 787 Stph) |

|

Superior™ MKIII 50-65 |

153 000 kg (337 300 lbs) |

450 kW (600 hp) |

1270 mm (50") |

6 375 Mtph (7 027 Stph) |

|

Superior™ MKIII 54-75 |

242 000 kg (533 500 lbs) |

600 kW (800 hp) |

1370 mm (54") |

7 500 Mtph (8 267 Stph) |

|

Superior™ MKIII 62-75 |

298 000 kg (657 000 lbs) |

600 kW (800 hp) |

1575 mm (62") |

8 750 Mtph (9 645 Stph) |

|

Superior™ MKIII 60-89 |

365 000 kg (805 000 lbs) |

750 kW (1000 hp) |

1525 mm (60") |

12 500 Mtph (13 779 Stph) |

|

Superior™ MKIII 70-89 |

430 000 kg (948 000 lbs) |

900 kW (1200 hp) |

1780 mm (70") |

15 000 Mtph (16 535 Stph) |

|

Superior™ MKIII 60-110 |

553 000 kg (1 220 000 lbs) |

1500 kW (2000 hp) |

1525 mm (60") |

17 000 Mtph (18 739 Stph) |

Gyratory Crusher Parts and Services

1. Gyratory Crusher Parts

Gyratory crushers play a crucial role in the crushing process. Even minor improvements in operating time or production capacity can significantly impact the overall productivity of the entire production system.

2. Crusher Services

Minimize maintenance downtime, increase production, reduce cost per ton, or meet specific crushing requirements.

3. Life Cycle Services

Metso offers bundled and customized service portfolios to provide you with readily available support.

PX旋回破√.png)