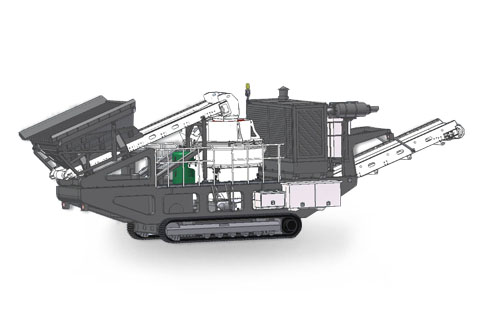

Lokotrack® mobile crushing plant is widely used in aggregate production and recycling applications. Thanks to its track-mounted design, it can be conveniently moved between different production sites.

Product Features

1. The Original Track-Mounted Mobile Plant

Lokotrack® mobile crushers are often referred to as "mobile crushing plants." As a track-mounted crushing unit, its excellent mobility maximizes productivity and reduces operating costs while enhancing safety and minimizing environmental impact.

The basic components of Lokotrack® mobile crushing plant are nearly identical to those of stationary crushers but with the added advantage of full mobility, allowing seamless movement even on slopes as steep as 1:10.

Lokotrack® mobile crushing plant is widely used in aggregate production, recycling, and mining operations.

2. Standalone or Integrated Operations

Many Lokotrack® models integrate crushers, conveyors, and screens on a single track-mounted frame. For models not pre-equipped with screens, they can be installed as needed.

The Lokotrack® can perform combined crushing, conveying, and screening tasks—functioning as a complete production line with just one unit.

Two or more Lokotrack® units can also be set up in sequence, forming a multi-stage integrated production line known as the "Lokotrack® Train."

3. Various Models for Different Needs

- Lokotrack® Mobile Cone Crushing Plant

Typically used for secondary, tertiary, and quaternary crushing, the mobile cone crusher can also serve as a primary crusher when the feed material size is small enough.

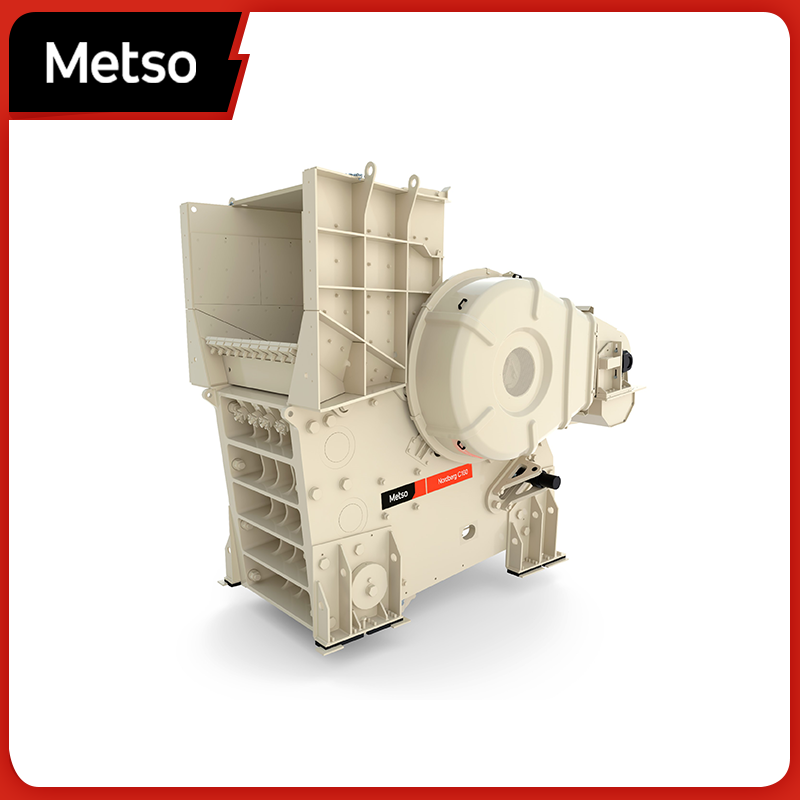

- Lokotrack® Mobile Impact Crushing Plant

This highly versatile crushing equipment is divided into two major categories based on the crushing technology employed:

The mobile impact crusher is equipped with an impact crusher and is commonly used for primary, secondary, and fine crushing.

The mobile vertical shaft impact (VSI) crusher features a VSI crusher, offering ultra-efficient final-stage crushing, producing high-quality cubical end products.

- Lokotrack® Mobile Jaw Crushing Plant

The widely popular mobile jaw crushing plant is primarily used as a primary crusher, breaking down material into smaller particles for further processing.

4. Efficient & Sustainable Hybrid Power

Lokotrack® e-Power mobile jaw and cone crushing plants can operate on either diesel or electric power. When grid power is available, the crushing plant can operate quietly and emission-free in urban environments, performing cost-effective crushing. In the absence of grid power, it is powered by modern, low-emission, and low-noise diesel engines.

Lokotrack® Mobile Crushing Plant Technical Parameters

|

Model |

Weight |

Crusher |

Crusher Drive Mode |

Engine Power |

|

|

Jaw crushing plant |

Lokotrack®LT96™ |

29,000 kg |

Nordberg®C96™ |

Hydraulic |

168 kW |

|

Lokotrack® LT106™ |

42,000 kg |

Nordberg®C106™ |

Hydraulic |

225kW |

|

|

Lokotrack® LT116™ |

50,000 kg |

Nordberg®C116™ |

Hydraulic |

310 kW |

|

|

Lokotrack® LT120™ |

62,600 kg |

Nordberg®C120™ |

Hydraulic |

310kW |

|

|

Lokotrack®LT120E™ |

66,500 kg |

Nordberg®C120™ |

Electric Drive |

310 kW |

|

|

Lokotrack® LT130E™ |

105,000 kg |

Nordberg®C130™ |

Electric Drive |

403 kW |

|

|

Cone crushing plant |

Lokotrack®LT200HP™ |

32,000 kg |

Nordberg®HP200™ |

Direct Drive |

310 kW |

|

Lokotrack®LT200HPS™ |

38,000 kg |

Nordberg®HP200™ |

Hydraulic |

310 kW |

|

|

Lokotrac®LT200HPX™ |

42,000 kg |

Nordberg®HP200™ |

Direct Drive |

310 kW |

|

|

Lokotrack®LT220GP™ |

38,500 kg |

Nordberg®GP220™ |

Direct Drive |

310 kW |

|

|

Lokotrack®LT300HP™ |

45,000 kg |

Nordberg®HP300™ |

Direct Drive |

403 kW |

|

|

Lokotrack®LT300GP™ |

46,000 kg |

Nordberg®GP300S™/GP330™ |

Direct Drive |

403kW |

|

|

Lokotrack®LT220D™ |

47,900 kg |

Nordberg®GP220™/HP200™ |

Direct Drive |

310 kW |

|

|

Lokotrack®LT330D™ |

71,000kg |

Nordberg®GP330™ |

Electric Drive |

563kW |

|

|

Impact crushing plant |

Lokotrack®LT1110™ |

35,400 kg |

Nordberg®NP1110M™ |

Direct Drive |

225kW |

|

Lokotrack®LT1213™ |

46,000 kg |

Nordberg®NP1213M™ |

Direct Drive |

310 kW |

|

|

Lokotrack®LT1213S™ |

52,300 kg |

Nordberg®NP1213M™ |

Direct Drive |

310 kW |

|

|

Lokotack®LT7150™ |

30,000 kg |

Barmac®B7150M™ |

Hydraulic |

310 kW |

|

The first Lokotrack® EC series models are now available!

Processing hard rock aggregates and recycled materials requires robust power and demanding conditions, while also delivering high-quality products promptly and at a reasonable cost. The new Lokotrack® EC series offers industry-leading reliability and performance. Thanks to its rugged design and practical digital tools, operating and maintaining the equipment has never been easier. The mobile crushers Lokotrack LT400J and LT350C are now released!