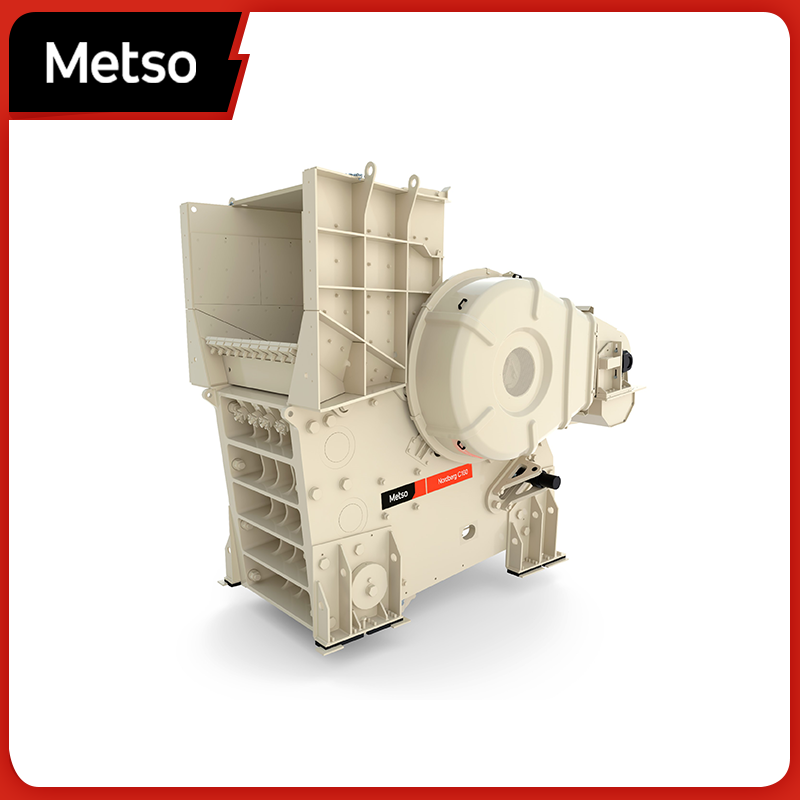

The world's most popular modern Nordberg® HP cone crusher is undergoing a revolution.

Efficiency is key to meeting the demands of aggregate and mining production, such as maximizing capacity and crushing ratio or increasing the output of specific aggregate product sizes. The new Nordberg HPe series cone crushers achieve higher performance and uptime in a more sustainable way.

Product Features

1. Performance Revolution

The kinetic energy of crushing and crusher cavity design have been further optimized, significantly improving crusher performance and adaptability to various working conditions.

- Perfect balance of crushing kinetics, cavity, locking force, and rated power.

- Higher head pivot point, greater installed power, stronger crushing force, and a new crushing cavity deliver revolutionary performance.

2. Extended Uptime

Crusher liner installation requires no backing material, simplifying liner replacement, reducing maintenance downtime, and positively impacting environmental protection and operator safety.

- Faster, simpler, and safer liner replacement with no backing material required.

- Anti-spin device extends liner life.

- IC70C automation system (optional) maximizes performance and protection.

- Ring bounce monitoring sensor (optional) enhances equipment protection.

3. Broader Application Range

The scope of application has expanded further with extra coarse, new coarse, fine, and extra-fine cavity options—optimizing crushing effects and performance.

- Three crushing kinetics options available.

- Reinforced and application-specific cavity designs. Cavity selection tools and cavity expert services support optimal choice.

- Adjustable crusher speed.

4. Enhanced Service Convenience

- No backing material required—liner replacement is faster, easier, and safer.

- Anti-spin device extends liner service life.

- Optimized tramp release cylinder fastening.

- New dedicated lifting tools for feed plate handling ensure safer hoisting and disassembly.

Spare Parts

High-quality cone crusher spare parts minimize unplanned downtime and ensure stable production. We offer a wide range of spare parts for Metso, Nordberg®, and Symons™ crushers, as well as third-party crushers. Depending on your application needs, we provide standard or customized components. With a global presence across 150+ locations, we offer comprehensive support—from recommended spare parts lists to installation upgrades.

Services

Maximize returns from your crushing circuit. Whether you need to reduce maintenance downtime, increase production, lower cost per ton, enhance sustainability, or meet specific crushing requirements, Metso has you covered. With over 1,500 field technicians, we provide the expertise and rapid response you need.

Technical Specifications

|

Model |

Weight (including drive device and base) |

Installed Power |

Feed Size |

Moving Cone Diameter |

|

Nordberg®HP200e™ |

12,300 kg (27,000 lbs) |

160 kW (200 HP) |

|

940 mm |

|

Nordberg®HP350e™ |

18,300 kg (40,300 lbs) |

250 kW (350 HP) |

|

1120 mm |

|

Nordberg®HP600e™ |

37,400 kg (82,500 lbs) |

450 kW (600 HP) |

|

1520 mm |

|

Nordberg®HP800e™ |

65,500 kg (144,400 lbs) |

600 kW (800 HP) |

356 mm |

1650 mm |

|

Nordberg®HP900e™ |

77,960 kg (171,870 lbs) |

700 kW (900 HP) |

356 mm (14") |

1780 mm |

多缸液压圆锥破碎机.png)