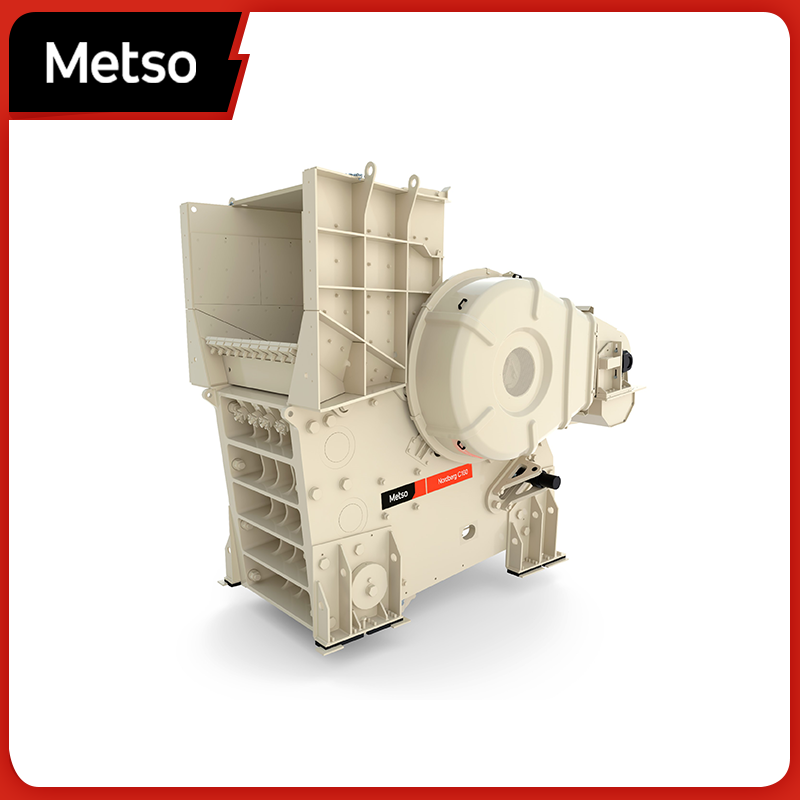

Renowned for delivering the highest crushing force in the market, Nordberg® MP™ Series cone crushers are specifically designed for mining applications to efficiently process both hard and soft rock formations.

Product Features

1. High Crushing Force with Guaranteed Uptime for Optimal Performance

With a longstanding history of exceptional performance across diverse mining operations, Nordberg® MP™ Series cone crushers are celebrated for their cost-effectiveness and superior crushing force.

This comprehensive product line encompasses multiple models, all rigorously field-tested in the most demanding mineral processing circuits.

2. Enhanced Operational Availability

Nordberg® MP™ Series cone crushers ensure increased uptime for your crushing needs. The fully automated hydraulic tramp release system facilitates the immediate passage of non-crushable materials through the crushing chamber, maintaining peak crushing force. Post-event, the system automatically reverts to the pre-set discharge setting.

Further boosting uptime, the hydraulic clearing system enables effortless material flow into the crushing chamber due to its generous vertical stroke, sustaining consistent stroke performance throughout the liner’s lifespan.

3. Unmatched Performance

Elevating cone crusher performance to unprecedented levels, Nordberg® MP™ Series delivers the highest power utilization among comparable crushers in the market.

Advanced crushing dynamics maximize power efficiency. With enhanced drive power, these crushers increase throughput, optimize power-to-production ratios, and improve energy efficiency.

4. Superior Reliability

Maintenance downtime translates to more than just lost operational hours. Nordberg® MP™ Series minimizes downtime with features like hydraulic chamber clearing and effortless discharge setting adjustments. Simplified one-button assembly/disassembly streamlines routine maintenance.

Engineered for rugged reliability, the rotating bowl compensates for feed segregation and uneven feed rates. Even with chamber wear, it prevents localized feed blockage and ensures consistently stable crushing outcomes.

5. Simplified Maintenance

Daily upkeep is expedited via the one-button disassembly function. Modular components enable swift replacements when required.

Every component detail is meticulously designed to ensure maintenance is both safe and straightforward.

Nordberg® MP™ Series Cone Crushers Technical Specifications

|

Model |

Weight* |

Capacity** |

|

Nordberg® MP800 |

120,570 kg (265,850 lbs) |

495-1935 mtph (545-2132 stph) |

|

Nordberg® MP1000 |

153,124 kg (337,604 lbs) |

615-2420 mtph (677-2667 stph) |

|

Nordberg® MP1250 |

153,985 kg (339,479 lbs) |

590-3025 mtph (650-3334 stph) |

|

Nordberg® MP2500 |

450,000 kg (992,080 lbs) |

2153-7166 mtph (2373-7899 stph) |

多缸液压圆锥破碎机.png)