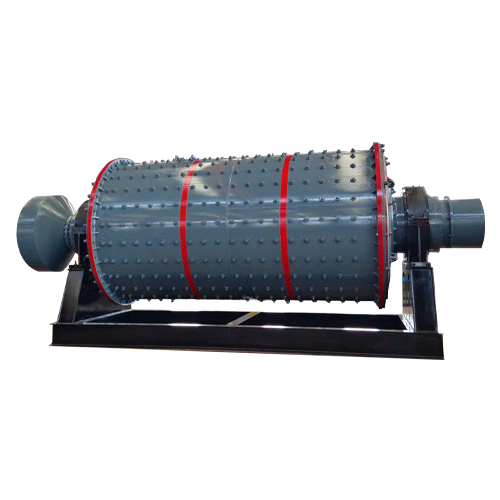

Ceramic ball mill is mainly used for mixing, milling of the materials, the fineness even, saving energy. It has two types, wet mills and dry mills. The machine could use different lining board according to product requirement to satisfy different requirement. The milling fineness depends on the milling time. The motor is started by the coupling which can reduce voltage and lower the starting electricity. The structure is divided into integral type and freestanding type. This products has lower investment, energy saving, structure novelty, easy and safe to operate, stable and reliable performance characteristics. It is suitable for mixing and milling of general and special materials. Users can choose the proper model, lining board and media as per the factors, such as: material's specific gravity and hardness, as well as output, etc.

MAIN MODELS AND TECHNICAL PARAMETERS:

| Model | Loading weight(ton/time) | Rotational speed(r/min) |

Reference power(kw) |

Liner material |

| 600×700 | 0.05 | 50 | 2.2 | Ceramics,Silica,Rubber, Metal(Equipped power will be a little different according to the liner material and the processed material) |

| 800×600 | 0.075 | 42 | 3 | |

| 900×1200 | 0.2 | 38.5 | 5.5 | |

| 1300×1500 | 0.5 | 33 | 7.5 | |

| 1500×1800 | 1.2 | 28.5 | 11 | |

| 1800×2000 | 1.5 | 24 | 15 | |

| 2600×2800 | 5 | 16.5 | 37 | |

| 3000×3800 | 10 | 14.5 | 57.2 | |

| 3200×4600 | 15 | 13.5 | 75 |