Grinding mills can be classified into ball mills, rod mills, and autogenous mills based on the grinding media used. They can operate in either wet or dry grinding modes.

Ball mills can be categorized by their discharge methods into grate-type and overflow-type mills, by their drive methods into peripheral-drive and central-drive mills, and by their main bearing types into plain-bearing and rolling-bearing (energy-saving) mills. They are primarily used for raw material grinding, with the finely ground material supplied to subsequent processes, such as in mineral processing plants, where it is fed to flotation machines or magnetic separators for mineral separation.

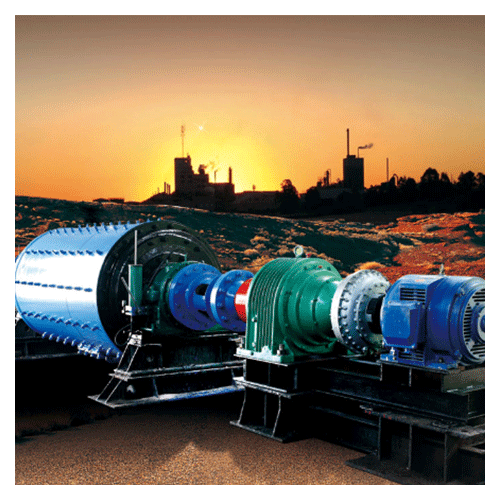

MQY Energy-Saving Overflow Ball Mill

The overflow ball mill is a type of ball mill that discharges ore pulp by overflow. The discharge end is equipped with reverse spirals to prevent steel balls and coarse ore from flowing out. It achieves finer grinding and is typically used for secondary or tertiary grinding in multi-stage grinding circuits.

Applications:

This machine is suitable for raw material grinding in industries such as mineral processing, metallurgy, chemicals, cement, and building materials, achieving a grinding fineness of up to 0.074 mm.

Structural Features:

1. The ball mill mainly consists of a transmission unit, slow-drive unit, main bearing unit, rotating unit (feeding unit, cylinder unit, discharge unit), lubrication system, and electrical control system.

2. Small ball mills (diameter < 2.1m):** Feature an integrated frame design for easy transportation and installation.

3. Large ball mills:

- Equipped with a jacking device for convenient maintenance.

- Include a slow-drive system for easier startup and maintenance.

- Utilize automatic spray lubrication for the gears, ensuring reliable lubrication, extending gear service life, and reducing lubricant consumption.

- Incorporate an air clutch for soft starting, minimizing the impact on the power grid during startup.

4. Energy-saving ball mills: Use double-row spherical roller bearings for the main bearings. When combined with permanent magnet synchronous motors and frequency control, they can save up to 30% energy compared to traditional ball mills.

Working Principle:

The rotating components of the ball mill, including the cylinder, are supported by main bearings at both ends. The motor drives the cylinder to rotate via the transmission mechanism. The material enters the cylinder through the feeding unit and is crushed by the impact and self-grinding action of the grinding media and the ore itself. As new material is continuously fed in, the ground material moves toward the discharge end and exits through the discharge port.

Technical Parameters:

| Model specification | Cylinder inner diameter(mm) | Cylinder length(mm) | Effective volume(m³) | Rotational speed of the cylinder(r/min) | Maximum ball charge(kg) | Feed size(mm) | Processing capacity(t/h) | Motor power(kw) | Weight(kg) | Overall dimensions (L×W×H) mm |

| MQY0918 | 900 | 1800 | 0.9 | 41.4 | 1900 | <20 | 0.5-2.2 | 18.5 | 5500 | 5080×2330×2020 |

| MQY0924 | 900 | 2400 | 1.2 | 41.4 | 2500 | <20 | 0.7-2.9 | 30 | 6400 | 5750×2330×2020 |

| MQY1224 | 1200 | 2400 | 2.4 | 36.7 | 4800 | <25 | 1.5-7 | 45 | 13200 | 6460×2860×2540 |

| MQY1230 | 1200 | 3000 | 3 | 36.7 | 6000 | <25 | 1.5-8 | 55 | 15300 | 7060×2860×2540 |

| MQY1530 | 1500 | 3000 | 4.5 | 31 | 8800 | <25 | 3-8 | 90 | 17500 | 7455×3260×2770 |

| MQY1535 | 1500 | 3500 | 5.3 | 31 | 10200 | <25 | 3.5-9 | 110 | 19000 | 7955×3260×2770 |

| MQY1540 | 1500 | 4000 | 6 | 31 | 11700 | <25 | 4-10 | 132 | 20500 | 8525×3310×2770 |

| MQY1830 | 1830 | 3000 | 6.7 | 28.8 | 12000 | <25 | 5-13 | 155 | 26000 | 8070×3770×3070 |

| MQY1835 | 1830 | 3500 | 7.8 | 28.8 | 14000 | <25 | 5.8-15 | 185 | 27500 | 8570×3770×3070 |

| MQY2130 | 2100 | 3000 | 9 | 23.6 | 19000 | <25 | 7-20 | 180 | 45000 | 9350×4920×4285 |

| MQY2135 | 2100 | 3500 | 10.5 | 23.6 | 22000 | <25 | 7-23 | 210 | 49000 | 9880×4920×4285 |

| MQY2435 | 2400 | 3500 | 14 | 23.6 | 25000 | <25 | 9-33 | 320 | 61000 | 9950×5220×4285 |

| MQY2445 | 2400 | 4500 | 18 | 23.6 | 32000 | <25 | 10-41 | 380 | 69000 | 10950×5200×4285 |

| MQY2736 | 2700 | 3600 | 18.5 | 21.7 | 36000 | <25 | 12-40 | 400 | 87000 | 11200×5815×4675 |

| MQY2745 | 2700 | 4500 | 23 | 21.7 | 45000 | <25 | 12-50 | 500 | 103000 | 12130×5815×4675 |

| MQY3236 | 3200 | 3600 | 26 | 18.5 | 50000 | <25 | 90-70 | 630 | 132000 | 12600×7200×5200 |

| MQY3245 | 3200 | 4500 | 32.5 | 18.5 | 625000 | <25 | 90-110 | 800 | 146000 | 13560×7200×5200 |

| MQY3645 | 3600 | 4500 | 41 | 18 | 75000 | <25 | 100-130 | 1250 | 165000 | 14250×7300×5700 |

| MQY3660 | 3600 | 6000 | 55 | 18 | 100000 | <25 | 100-170 | 1600 | 192000 | 15750×7300×5700 |

Note: In addition to the model specifications listed above, custom manufacturing is available to meet specific user requirements.