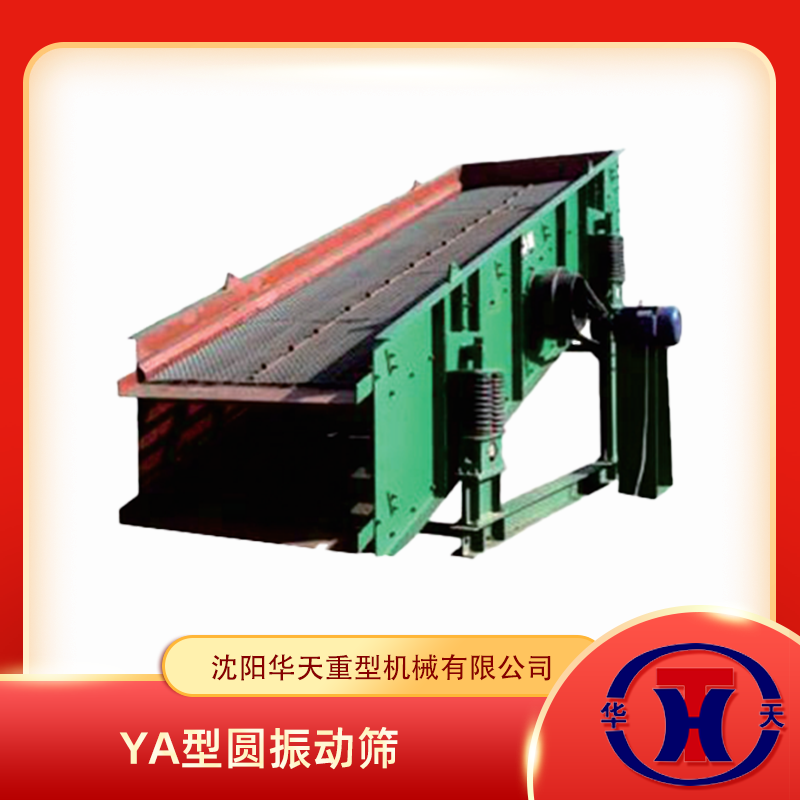

Product Introduction

The YA circular vibrating screen series has been introduced to the United States by R S Company's advanced technology can be widely used for dry classification of various materials in departments such as coal metallurgy, transportation, building materials, power, and chemical engineering. This series of sun drying machines is divided into single-layer, double-layer, and three-layer screen surfaces, and there are light and heavy types. The screen mesh has three types: woven punching and polyurethane; The feeding box is an optional component; The electric motor can be installed on the left or right side. If there are no special requirements from the user, it should be installed according to the installation diagram and supplied.

Advantages and Characteristics

The screening machine adopts a frame structure, ring groove rivet connection, advanced structure, and is sturdy and durable; The vibrator adopts large clearance bearings. Thin oil lubrication, low noise, and long service life; The other component has strong versatility and is easy to maintain.

Technical Parameter

|

Model |

Sieve surface |

Feeding grain size(mm) |

Processing capacity(t/h) |

Vibration frequency |

Double amplitude |

Motor |

|||||

|

Muber of layers |

Area(m²) |

Dip angle |

Sieve size(mm) |

Structure |

Model |

Power(kW) |

|||||

|

YA1848 |

1 |

8.6 |

20° |

6~50 |

weaving |

≤200 |

150~525 |

845 |

9.E |

Y160L4 |

15 |

|

2YA1848 |

2 |

8.6 |

20° |

6~50 |

weaving |

≤200 |

150~525 |

845 |

9.5 |

Y160L4 |

15 |

|

YAH1848 |

1 |

8.6 |

20° |

30~150 |

Punching |

0~150 |

250~1000 |

755 |

11 |

Y180M4 |

18.5 |

|

2YAH1848 |

2 |

8.6 |

20° |

30~150 |

Punching |

≤400 |

250~1000 |

755 |

11 |

Y180L4 |

15 |

|

YA2148 |

1 |

10 |

20° |

6~50 |

weaving |

≤210 |

180~630 |

748 |

9.5 |

Y180M4 |

18.5 |

|

2YA2148 |

2 |

10 |

20° |

6~50 |

weaving |

≤210 |

180~630 |

748 |

9.5 |

Y180L4 |

22 |

|

YAH2148 |

1 |

10 |

20° |

13~200 |

Punching |

≤400 |

270~1200 |

708 |

11 |

Y180M4 |

18.5 |

|

2YAH2148 |

2 |

10 |

20° |

30~150 |

upper punching and lower weaving |

≤400 |

270~1200 |

708 |

11 |

Y180L4 |

22 |

|

YA2160 |

1 |

12.6 |

20° |

3~80 |

weaving |

≤200 |

230~800 |

748 |

9.5 |

Y180M4 |

18.5 |

|

2YA2160 |

2 |

12.6 |

20° |

6~50 |

weaving |

≤200 |

230~800 |

748 |

9.5 |

Y200L4 |

30 |

|

YAH2160 |

1 |

12.6 |

20° |

30~150 |

Punching |

≤400 |

350~1500 |

708 |

11 |

Y200L4 |

30 |

|

2YAH2160 |

2 |

12.6 |

20° |

30~150 |

upper punching and lower weaving |

≤400 |

350~1500 |

708 |

11 |

Y200L4 |

30 |

|

YA2448 |

1 |

11.5 |

20° |

6~50 |

weaving |

≤200 |

200~700 |

748 |

9.5 |

Y180M4 |

18.5 |

|

YAH2448 |

2 |

11.5 |

20° |

6~50 |

Punching |

≤400 |

310~1300 |

708 |

11 |

Y200L4 |

30 |

|

YA2460 |

1 |

14.4 |

20° |

6~50 |

weaving |

≤200 |

260~780 |

748 |

9.5 |

Y200L4 |

30 |

|

2YA2460 |

2 |

14.4 |

20° |

6~50 |

weaving |

≤200 |

260~780 |

748 |

9.5 |

Y200L4 |

30 |

|

YAH2460 |

1 |

14.4 |

20° |

30~150 |

Punching |

≤400 |

400~1700 |

708 |

11 |

Y200L4 |

30 |

|

2YAH2460 |

2 |

14.4 |

20° |

30~150 |

upper punching and lower weaving |

≤400 |

400~1700 |

708 |

11 |

Y200L4 |

30 |