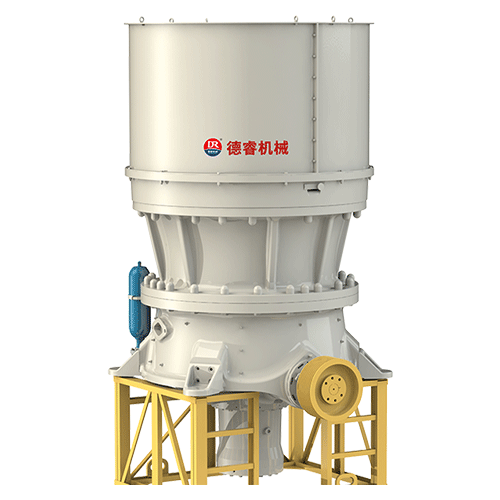

Product Introduction

The HTGP single cylinder hydraulic cone crusher is a highly efficient medium and fine crushing cone crusher developed and developed by our company based on similar products at home and abroad. Its technical level is also one of the leading levels in the domestic crushing industry. This product is suitable for crushing hard, medium hard ore and rocks, as well as medium-sized sand and gravel, limestone, quartz, granite or rock based materials and metal ores, with a compressive strength of ≤ 300Mpa and other stone materials. This product is characterized by its small size, light weight, and high output as an efficient medium to fine crushing equipment.

The HTGP single cylinder hydraulic cone crusher is a highly efficient medium and fine crushing cone crusher developed and developed by our company based on similar products at home and abroad. Its technical level is also one of the leading levels in the domestic crushing industry. This product is suitable for crushing hard, medium hard ore and rocks, as well as medium-sized sand and gravel, limestone, quartz, granite or rock based materials and metal ores, with a compressive strength of ≤ 300Mpa and other stone materials. This product is characterized by its small size, light weight, and high output as an efficient medium to fine crushing equipment.

Technical Parameter

1. At present, the HTGP-X fine crushing series cone crusher usually provides three types of interchangeable crushing chamber types. The HTGP-Z medium crushing series cone crusher usually provides two types of interchangeable crushing chamber types to adapt to different feed size and particle size requirements. The chamber type is changed by replacing the crushing wall and rolling mortar wall, and two to three strokes are available for selection.

2. The production capacity in the table is for reference only and only applicable to a bulk density of 1.6t/m ³ The parameters of medium hardness granite stones and stone materials when filling the crushing chamber, and the reference production of other materials can be approximately obtained through bulk density conversion.

3. Discharge port and cavity type

The minimum discharge port depends on various factors such as stone type (pebble or rock), cavity type, stroke (eccentricity), crushing ratio, overcrowding feeding level, uniform feeding level variation, feeding grading, and cavity wear.

The setting of the minimum discharge port is limited by the motor power and high pressure. The limited motor power and stroke have a protective effect on the main engine and are not allowed to be used beyond the design range.

The minimum discharge port provided is a reference for granite during continuous and stable operation of the crusher. The influence of feeding is a particularly important factor (especially in the intermediate crushing chamber type), which may cause the inability to adjust to the minimum discharge port.

Selection of stroke: When the stroke decreases, the allowable discharge port decreases. When the size of the discharge port is not constant, the output decreases; When the stroke increases and the allowable discharge port increases, the output increases when the size of the discharge port is fixed.

4. On site requirements for HTGP single cylinder hydraulic cone crusher:

Power supply voltage: 380V/220V.

B ambient temperature: -20 ℃~40 ℃.

C altitude ≤ 1000 meters.

If it exceeds the altitude, special requirements should be made.

5. HTGP single cylinder hydraulic cone crusher matching motor:

1) Main motor

2) Lubricating oil station motor

3) Hydraulic system motor

4) Cooling motor

5) Positive pressure fan motor

Technical Parameter

HTGP series production capacity(t/h)

|

Specification and model |

Stroke(mm) |

Maximum feeding(mm) |

Tight edged discharge port(mm) |

Motor Power |

||||||||

|

8 |

12 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

||||

|

HTGP100 |

18 |

60 |

35-40 |

50-55 |

55-65 |

65-75 |

75-85 |

90-100 |

105-115 |

|

|

110 |

|

25 |

120 |

45-50 |

60-65 |

65-75 |

75-90 |

85-105 |

100-125 |

115-135 |

|

|

||

|

HTGP200 |

18 |

60 |

60-70 |

75-90 |

85-105 |

100-125 |

135-150 |

160-175 |

170-190 |

|

|

200 |

|

25 |

150 |

|

90-100 |

110-130 |

125-155 |

160-180 |

185-210 |

200-250 |

|

|

||

|

HTGP300 |

25 |

70 |

100-120 |

110-135 |

130-160 |

150-180 |

170-200 |

200-230 |

230-260 |

250-290 |

270-310 |

250 |

|

32 |

160 |

110-135 |

130-150 |

160-200 |

180-220 |

200-250 |

230-280 |

260-310 |

280-320 |

300-34 |

||

|

HTGP500 |

25 |

80 |

100-120 |

120-150 |

140-170 |

160-190 |

190-220 |

220-250 |

250-280 |

280-310 |

330-370 |

315 |

|

32 |

180 |

|

150-170 |

170-200 |

200-230 |

250-270 |

280-300 |

310-340 |

370-420 |

430-500 |

||

HTGP-S series production capacity(t/h)

|

Specification and model |

Stroke(mm) |

Maximum feeding(mm) |

Tight edged discharge port(mm) |

Motor Power |

||||||||

|

35 |

40 |

45 |

50 |

55 |

60 |

65 |

70 |

75 |

||||

|

HTGP100S |

18 |

210 |

135-150 |

145-165 |

155-175 |

165-185 |

175-190 |

180-205 |

|

|

|

110 |

|

25 |

250 |

160-180 |

170-200 |

180-210 |

190-220 |

200-230 |

205-235 |

|

|

|

||

|

HTGP2005 |

25 |

210 |

160-190 |

180-210 |

200-230 |

230-250 |

250-270 |

270-300 |

|

|

|

200 |

|

32 |

280 |

190-240 |

210-260 |

230-280 |

260-310 |

290-340 |

310-370 |

|

|

|

||

|

HTGP300S |

25 |

240 |

250-300 |

290-340 |

320-350 |

350-380 |

380-410 |

410-440 |

440-470 |

|

|

250 |

|

32 |

320 |

340-390 |

370-420 |

400-440 |

430-470 |

470-500 |

500-510 |

530-540 |

|

|

||

|

HTGP500S |

25 |

320 |

|

|

|

500-550 |

550-600 |

600-650 |

650-700 |

700-750 |

750-800 |

315 |

|

32 |

420 |

|

|

|

650-700 |

700-750 |

750-800 |

825-875 |

900-950 |

950-1000 |

||

单缸液压圆锥破碎机2.png)