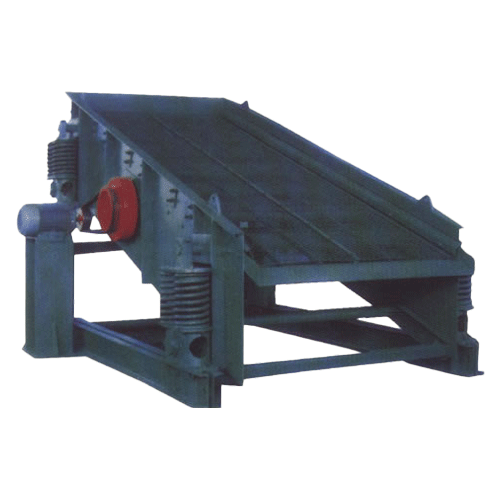

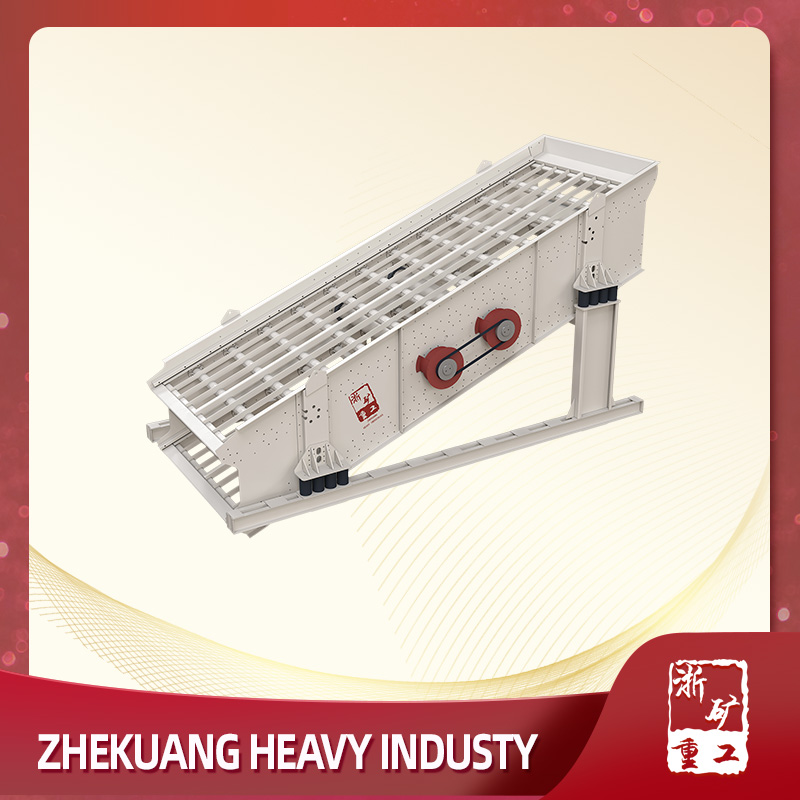

The circular vibrating screen gets its name from the nearly circular motion trajectory of the screen box. It is mainly used for screening and classifying materials, and can also be used for desliming, dewatering, and medium removal of materials. It is suitable for coal, limestone, crushed stone, gravel, metallic or non-metallic ores, and other materials.

Working principle: The motor drives the eccentric block of the exciter to rotate at high speed via a V-belt, generating a large centrifugal force that excites the screen box to produce a certain amplitude of vibration. Materials on the screen undergo continuous projectile motion due to the impact force transmitted by the screen box on the inclined screen surface; during contact with the screen surface, particles smaller than the screen mesh pass through, thereby completing the screening process. According to material types and user requirements, the screen mesh can be made of high manganese steel woven mesh or polyurethane mesh. The screen plates are available in single-layer, double-layer, and multi-layer configurations, and the motor can be installed on either the left or right side of the screen box.

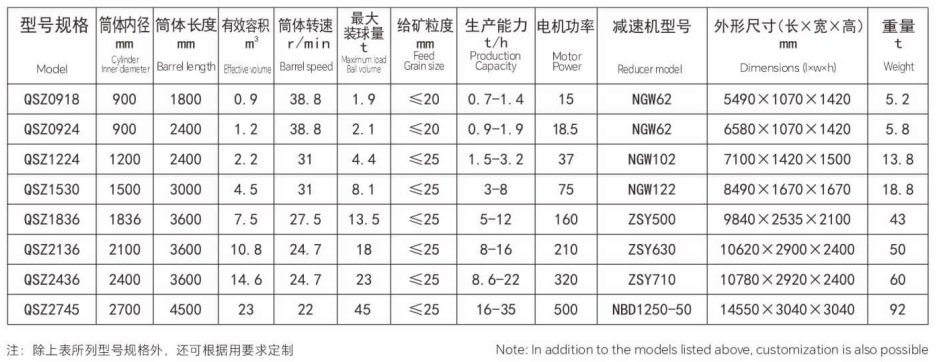

Main models and technical parameters

圆振动筛.png)