Product Introducion

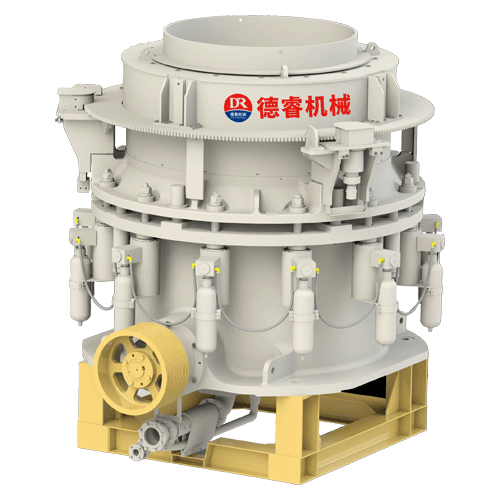

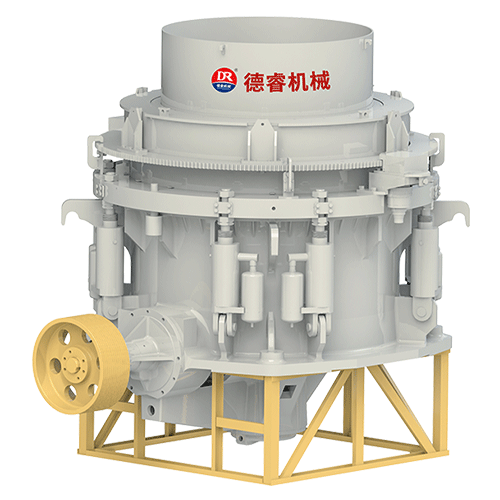

The HTP series high-efficiency cone crusher is developed based on the latest technology in the United States and has a world-class cone crusher. It not only improves the production capacity and crushing efficiency of the cone crusher, but also expands its application range. From limestone to basalt, from stone production to various ore crushing, it can provide unparalleled crushing performance in various crushing operations. It is the latest generation product that replaces spring cone crushers and general hydraulic cone crushers in today's mining and construction industries. It is the most ideal equipment for crushing in stone factories and various metal mining industries.

The HTP series high-efficiency cone crusher is developed based on the latest technology in the United States and has a world-class cone crusher. It not only improves the production capacity and crushing efficiency of the cone crusher, but also expands its application range. From limestone to basalt, from stone production to various ore crushing, it can provide unparalleled crushing performance in various crushing operations. It is the latest generation product that replaces spring cone crushers and general hydraulic cone crushers in today's mining and construction industries. It is the most ideal equipment for crushing in stone factories and various metal mining industries.

Product Features and Technological Advantages

1. The crushing ratio is high, the production efficiency is high, and the perfect combination of high speed and large stroke greatly increases the yield and the proportion of one-time qualified products;

2. The fixed spindle design makes the force on each component more reasonable and the power conversion more effective;

3. The product has a more stable particle size composition and more finely fragmented products;

4. Fully hydraulic standard configuration, PLC centralized control system, simple operation and flexible adjustment;

5. Adjustment of hydraulic discharge port

By using a hydraulic motor to drive the adjustment sleeve, coupled with a hydraulic locking cylinder to lock the entire set, you can complete the adjustment of the discharge port without the need to arrive at the site;

6. Improved bumper and accumulator

When the crusher suddenly increases in iron or other loads, the hydraulic oil of the safety cylinder can instantly flow back to the accumulator, quickly lifting the piston rod, thereby better protecting the crusher components and reducing the damage of impact loads to the machine;

7. Adjusting the sleeve locking

After adjusting the discharge port, the locking of the adjusting sleeve is completed by the hydraulic locking cylinder. You can press a button to complete the locking and adjusting of the whole set, greatly reducing labor intensity, saving downtime, and ensuring the reliability of locking;

8. Integrated base

The newly designed integrated base includes installation modules such as the main equipment, motor, and belt cover, simplifying the equipment installation steps and bringing great convenience to users.

Technical Parameter

HTP series production capacity reference (t/h):

|

Tight edge discharge port |

|||||||||||||

|

Model |

t/h |

6mm |

8mm |

10mm |

13mm |

16mm |

19mm |

22mm |

25mm |

32mm |

38mm |

45mm |

51mm |

|

HP100 |

t/h |

45-55 |

50-60 |

55-70 |

60-80 |

70-90 |

75-95 |

80-100 |

85-110 |

100-140 |

|

|

|

|

HP200 |

t/h |

|

|

90-120 |

120-150 |

140-180 |

150-190 |

160-200 |

170-220 |

190-235 |

210-250 |

|

|

|

HP300 |

t/h |

|

|

115-140 |

150-185 |

180-220 |

200-240 |

220-260 |

230-280 |

250-320 |

300-380 |

350-440 |

|

|

HP400 |

t/h |

|

|

140-175 |

185-230 |

225-280 |

255-320 |

275-345 |

295-370 |

325-430 |

360-490 |

410-560 |

465-630 |

|

HP500 |

t/h |

|

|

175-220 |

230-290 |

280-350 |

320-400 |

345-430 |

365-455 |

405-535 |

445-605 |

510-700 |

580-790 |

|

HP800 |

t/h |

|

|

260-335 |

325-425 |

385-500 |

435-545 |

470-600 |

495-730 |

545-800 |

600-950 |

690-1050 |

785-1200 |

.jpg)

多缸液压圆锥破碎机.png)