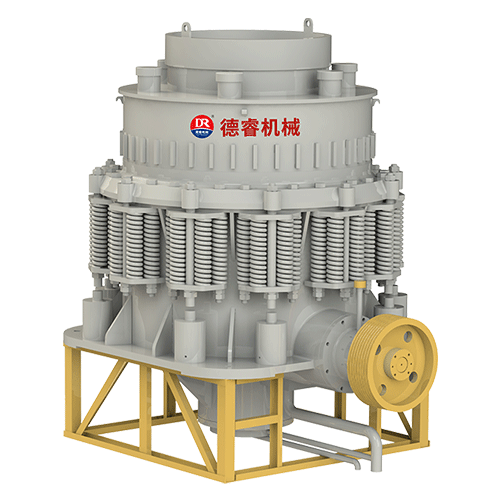

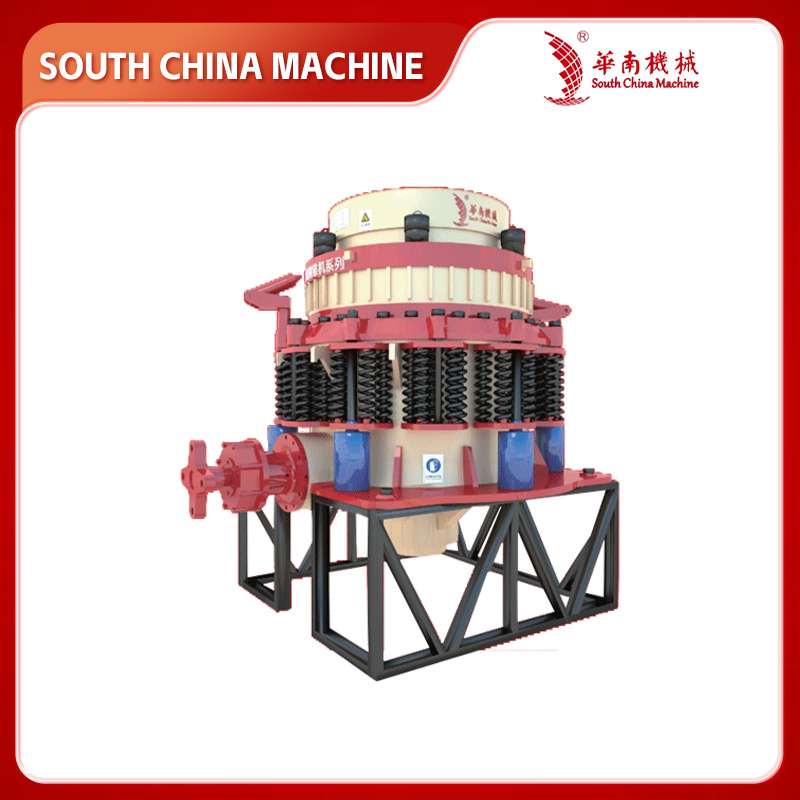

Production Introduction

The Simmons cone crusher has the characteristics of high production capacity, fine product particle size, good product shape, light equipment weight, convenient maintenance, and easy operation. The performance of the spring cone crusher is superior to that of the spring cone crusher in terms of output, product particle size uniformity, fineness of the crusher product, component life, operation rate, and production maintenance management costs.

Advantage and Characteristic

1. Two types of crushing chamber structures, with strong adaptability and a wide range of product particle sizes. The Simmons spring safety system can provide safe and effective overload protection, as well as a comprehensive lubrication system.

2. High degree of automation. Compared with traditional domestic cone crushers, Simmons cone crushers adopt hydraulic locking, hydraulic adjustment, hydraulic cleaning and other devices.

3. The Simmons cone crusher is designed and manufactured with high quality, long service life, convenient maintenance, and low cost. All maintenance work can be easily carried out on the upper part of the machine.

4. It has strong crushing power and can provide a large production capacity. One reason is that its force is longer than other existing cone crushers on the market, which is reflected in the main shaft. It has the advantages of reducing the load on the eccentric shaft, lowering the temperature of the bearing, and extending the service life of the bearing. The second is that the maximum crushing cone stroke will provide greater production capacity. The Simmons cone crusher is designed with a large eccentricity and just the right cone angle, giving it a larger discharge volume. The third factor is the large crushing force combined with the free fall of materials, which makes the crusher highly efficient and reduces energy consumption.

Technical Parameter

|

Model |

Crushing cone diameter(feet) |

Cavity type |

Size of feeding port(mm) |

Minimum ore discharge port(kW) |

Main motor power(kW) |

Size of ore discharge port(mm) |

Output(t/h) |

||

|

Closed edge |

Opening edge |

||||||||

|

PYS-B0910 |

3Ft |

Standard type |

Fine type |

83 |

102 |

10 |

75 |

10-22 |

45-91 |

|

PYS-B0917 |

Coarse type |

159 |

175 |

13 |

13-38 |

59-163 |

|||

|

PYS-B0918 |

Extra coarse type |

163 |

178 |

25 |

25-38 |

118-163 |

|||

|

PYS-D0904 |

Short head type |

Fine type |

13 |

41 |

3 |

3-13 |

27-90 |

||

|

PYS-D0906 |

Coarse type |

33 |

60 |

3 |

3-16 |

27-100 |

|||

|

PYS-D0907 |

Extra coarse type |

51 |

76 |

6 |

6-19 |

59-127 |

|||

|

PYS-B1313 |

4¼Ft |

Standard type |

Fine type |

109 |

137 |

13 |

155 |

13-31 |

109-180 |

|

PYS-B1321 |

Medium type |

188 |

210 |

16 |

16-38 |

130-250 |

|||

|

PYS-B1324 |

Coarse type |

216 |

241 |

19 |

19-51 |

170-350 |

|||

|

PYS-B1325 |

Extra coarse type |

238 |

259 |

25 |

25-51 |

236-360 |

|||

|

PYS-D1306 |

Short head type |

Fine type |

29 |

64 |

5 |

5-16 |

50-160 |

||

|

PYS-B1308 |

Medium type |

54 |

89 |

6 |

6-16 |

74-160 |

|||

|

PYS-B1310 |

Coarse type |

70 |

105 |

10 |

10-25 |

98-215 |

|||

|

PYS-B1313 |

Extra coarse type |

98 |

133 |

19 |

19-25 |

180-225 |

|||

|

PYS-B1620 |

5½Ft |

Standard type |

Fine type |

188 |

209 |

16 |

240 |

16-38 |

181-327 |

|

PYS-B1624 |

Medium type |

213 |

241 |

22 |

22-51 |

258-417 |

|||

|

PYS-B1626 |

Coarse type |

241 |

269 |

25 |

25-64 |

300-635 |

|||

|

PYS-B1636 |

Extra coarse type |

331 |

368 |

38 |

38-64 |

431-630 |

|||

|

PYS-D1607 |

Short head type |

Fine type |

35 |

70 |

6 |

6-13 |

100-209 |

||

|

PYS-D1608 |

Medium type |

54 |

89 |

6 |

6-19 |

136-310 |

|||

|

PYS-D1613 |

Coarse type |

98 |

133 |

10 |

10-25 |

190-336 |

|||

|

PYS-D1614 |

Extra coarse type |

117 |

158 |

13 |

13-25 |

253-336 |

|||

|

PYS-BC2127 |

7Ft |

Standard type |

Fine type |

253 |

278 |

19 |

400 |

19-38 |

540-800 |

|

PYS-BC2133 |

Medium typle |

303 |

334 |

25 |

25-51 |

670-1100 |

|||

|

PYS-BC2136 |

Coarse type |

334 |

369 |

31 |

31-64 |

870-1400 |

|||

|

PYS-BC2146 |

Extra coarse type |

425 |

460 |

38 |

38-64 |

970-1500 |

|||

|

PYS-DC2110 |

Short head type |

Fine type |

51 |

105 |

6 |

6-16 |

300-450 |

||

|

PYS-DC2113 |

Medium type |

95 |

133 |

10 |

10-19 |

390-560 |

|||

|

PYS-DC2117 |

Coarse type |

127 |

178 |

13 |

13-25 |

500-660 |

|||

|

PYS-DC2120 |

Extra coarse type |

152 |

203 |

16 |

16-25 |

560-720 |

|||