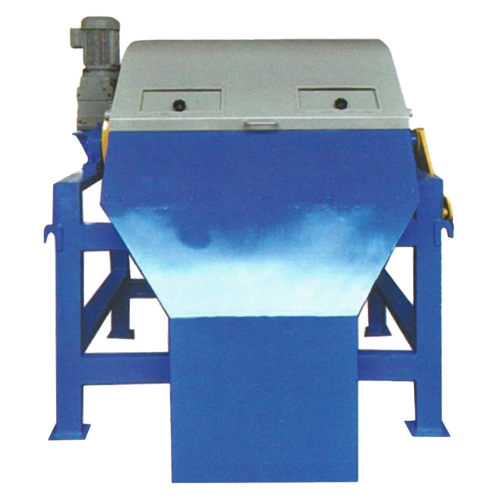

The series of magnetic separator is the most widely used wet magnetic separator. It is suitable for the wet magnetic separation of the materials whose granularity is below 6mm such as magnetite, pyrrhotite, calcined ore and ilmenite, and can also be used for removing iron from the materials such as coal, non-metal ore and building material. The magnetic system of magnetic separator is a compound of fine ferrite material and rare earth magnets, and the average magnetic induction intensity of the surface of the cylinder is 100-600 MT (that is, Gaussian 1000-6000). According to specific need, customers can choose from many kinds of magnetic separators with different surface magnetic intensity such as downstream type, reflux-type and semi-reflux type. The product has the advantages of simple structure, large handling capability, easy to use and easy to maintain etc.

Downstream type (CTS): The direction of feeding is the same with the direction of rotating cylinder or the direction of the movement of magnetic products. Such machines is applied to the roughing and fining of magnetic minerals of 0-6mm, moreover, the grade of ore concentrate is high.

Reflux-type (CTN): The direction of feeding is opposite with the direction of rotating cylinder or the direction of the movement of magnetic products. Such machines is applied to the roughing and scavenging of magnetic minerals 0-0.6mm, as well as the coal industry's heavy-medium recovery. The gangue of this type of machine have little metal loss, high metal recovery, so it is best to use it recovery gangue, but the ore concentrate grade is not high enough.

Semi-reflux type (CTB): The direction of feeding or magnetic products is the same with the direction of rotating cylinder and the direction of cylinder rotation is opposite with the direction of non-magnetic products. The lower part of the machine are plugged wash pipe to regulate the thickness of concentration. This model applied to the roughing and fining of strong magnetic minerals of 0-0.5mm, and the recovery rate and ore concentrate grade is high.

MAIN MODELS AND TECHNICAL PARAMETERS:

| Model and specification | Drum Diameter × Length (mm) | Rotation Speed (r/min) | Magnetic Intensity (mT) | Feeding Concentration (%) | Processing Capacity (Dry Metric) (t/h) | Motor power(kw) | Overall dimensions (L×W×H)(mm) | Weight(kg) |

| CTB46 | Φ400×600 | 45 | 120-150 | 25-35 | 1-3 | 1.1 | 1300×800×800 | 400 |

| CTB49 | Φ400×900 | 45 | 120-150 | 25-35 | 2-4 | 1.1 | 1600×800×800 | 550 |

| CTB69 | Φ600×900 | 38 | 120-150 | 25-35 | 8-10 | 1.5 | 1700×1050×1100 | 600 |

| CTB612 | Φ600×1200 | 38 | 120-150 | 25-35 | 10-15 | 1.5 | 2000×1050×1100 | 750 |

| CTB615 | Φ600×1500 | 38 | 120-150 | 25-35 | 15-20 | 2.0 | 2300×1050×1100 | 870 |

| CTB79 | Φ700×900 | 33 | 120-150 | 25-35 | 10-15 | 1.5 | 1700×1500×1300 | 670 |

| CTB712 | Φ700×1200 | 33 | 120-150 | 25-35 | 15-20 | 2.2 | 2100×1500×1300 | 900 |

| CTB715 | Φ700×1500 | 33 | 120-150 | 25-35 | 25-30 | 2.2 | 2400×1500×1300 | 1100 |

| CTB718 | Φ700×1800 | 33 | 120-150 | 25-35 | 30-35 | 3 | 2750×1500×3100 | 1300 |

| CTB912 | Φ900×1200 | 30 | 120-150 | 25-35 | 25-30 | 3 | 2200×1500×1600 | 1100 |

| CTB915 | Φ900×1500 | 30 | 120-150 | 25-35 | 30-35 | 3 | 2500×1500×1600 | 1350 |

| CTB918 | Φ900×1800 | 30 | 120-150 | 25-35 | 35-45 | 4 | 2850×1500×1600 | 1700 |

| CTB920 | Φ900×2000 | 30 | 120-150 | 25-35 | 45-50 | 4 | 3150×1500×1600 | 2150 |

| CTB1012 | Φ1050×1200 | 25 | 120-150 | 25-35 | 30-40 | 3 | 2200×1600×1700 | 1250 |

| CTB1015 | Φ1050×1500 | 25 | 120-150 | 25-35 | 40-55 | 4 | 2550×1600×1700 | 1500 |

| CTB1018 | Φ1050×1800 | 25 | 120-150 | 25-35 | 55-100 | 4 | 2850×1600×1700 | 1750 |

| CTB1020 | Φ1050×1200 | 25 | 120-150 | 25-35 | 60-120 | 5.5 | 3250×1600×1700 | 2100 |

| CTB1024 | Φ1050×2400 | 25 | 120-150 | 25-35 | 65-125 | 5.5 | 3550×1600×1700 | 2500 |

| CTB1215 | Φ1200×1500 | 20 | 120-150 | 25-35 | 50-90 | 4 | 2550×1950×2100 | 2300 |

| CTB1218 | Φ1200×1800 | 20 | 120-150 | 25-35 | 55-100 | 5.5 | 2950×1950×2100 | 2800 |

| CTB1220 | Φ1200×2000 | 20 | 120-150 | 25-35 | 60-110 | 5.5 | 3250×1950×2100 | 3400 |

| CTB1224 | Φ1200×2400 | 20 | 120-150 | 25-35 | 70-130 | 7.5 | 3650×1950×2100 | 4100 |

| CTB1230 | Φ1200×3000 | 20 | 120-150 | 25-35 | 80-150 | 7.5 | 4000×1950×2100 | 5000 |